En este caso, desarrollamos un pinza magnética para una aplicación automatizada de manipulación de materiales en la planta de producción de un cliente. Como fabricante de imanes electropermanentes, colaboramos estrechamente con el cliente para diseñar una pinza que pudiera montarse en el extremo de un brazo robótico y funcionar junto con un sistema de visión.

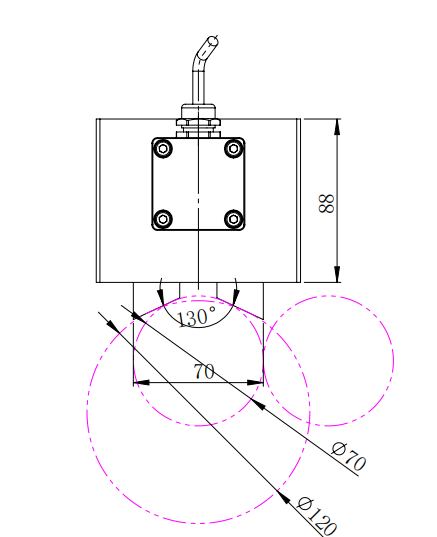

El cliente necesitaba manipular piezas de eje redondo con una amplia gama de tamaños. Las piezas tienen diámetros de 70 mm a 120 mm, longitudes de 100 mm a 1.800 mm y un peso máximo de 40 kg. El proceso de manipulación requería un agarre estable, un posicionamiento preciso y un movimiento suave durante el funcionamiento automatizado.

Basándonos en estos requisitos, diseñamos una pinza magnética utilizando dos imanes electropermanentes HEPMT-1611G que trabajan conjuntamente. Esta configuración proporciona una fuerza de sujeción suficiente y permite al robot manipular ejes cortos y largos. La pinza magnética se monta directamente en la brida del robot y se conecta al sistema de control para un sencillo control magnético on/off.

Durante las pruebas in situ, la pinza magnética demostró un rendimiento fiable en combinación con el sistema de visión. El robot fue capaz de identificar, agarrar, levantar y transferir ejes de diferentes tamaños sin necesidad de ajustes mecánicos. El método de agarre sin contacto ayudó a proteger la superficie de las piezas y redujo la necesidad de complejas fijaciones mecánicas.

La prueba también demostró que la pinza magnética podía adaptarse bien a los cambios de longitud y posición de las piezas. Gracias al guiado por visión, el robot mantuvo unos puntos de agarre constantes y un movimiento estable durante todo el proceso de manipulación. El diseño electropermanente garantizaba una sujeción segura durante el funcionamiento y sólo requería energía durante la magnetización y la desmagnetización.

Este proyecto confirma que un diseño pinza magnética es muy adecuada para la manipulación automatizada de piezas cilíndricas de acero. Ofrece una solución sencilla, estable y flexible para aplicaciones robóticas en sistemas de automatización modernos.