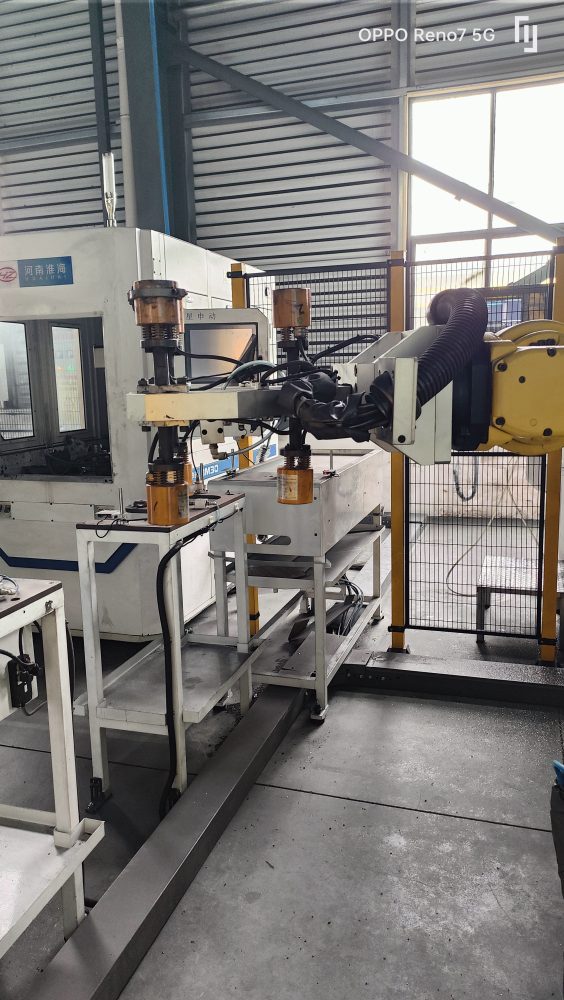

En las fábricas de piezas de automóviles, el mecanizado de discos de freno debe ser rápido y preciso. Trabajamos con un cliente para configurar un sistema en el que los brazos robóticos utilizan pinzas magnéticas para cargar y descargar piezas automáticamente.

Cómo funciona el sistema

La instalación utiliza seis unidades magnéticas (modelo HEPM1-58-D), dispuestas en dos pinzas. Se turnan para mover discos de freno que pesan entre 15 y 20 kg, completando un ciclo cada 15 segundos. Un robot maneja ahora dos máquinas a la vez, manteniendo el flujo de trabajo sin necesidad de personas que muevan las piezas.

Mejor que la antigua

Antes, una persona manejaba cada máquina. Ahora, el robot lo hace todo, sin sujeción manual ni posicionamiento a mano. Esto ha hecho que el proceso sea más de cinco veces más rápido y ha eliminado la necesidad de un operario en estas estaciones.

Bueno para las piezas y las personas

Las pinzas magnéticas sujetan el disco de freno desde el centro sin tocar la superficie, por lo que no se producen arañazos ni daños. Tampoco aprietan el disco, por lo que no se dobla. Esto mantiene las piezas en buen estado.

Además, sin trabajadores que levanten piezas pesadas, hay menos posibilidades de lesiones y menos cansancio al final del día. El taller también está ahora más ordenado y organizado.

Por qué es importante

Este tipo de sistema muestra cómo las pinzas magnéticas y los robots pueden trabajar juntos para mejorar el mecanizado: más rápido, más seguro y más ordenado. Es un práctico paso adelante para las fábricas que fabrican piezas como discos de freno.