Electro Permanent Coil Lifting Magnets

- Minimized Contact: No pressure marks or edge damages to coil material, unlike C-hooks.

- Space-Saving Design: Enables side-by-side coil storage, saving up to 30% space

- Integration Option:Equipped with an interface for easy integration into automated production processes.

- High-Durability& Minimum Maintenance: no moving parts

- Remote Control: Single operatorand digital push buttons

- High Safety: 3:1 safety factor.

What is Electro Permanent Coil Lifting Magnets

HC Series Electro Permanent Coil Lifting Magnets are designed for the precise and secure handling of steel coils in various configurations, including horizontal or vertical eye setups, improve efficiency by allowing a single operator to manage heavy coils with ease.

Energy-efficient and customizable, these magnets are tailored to meet specific lifting needs, making them indispensable in steel production facilities, warehousing, and logistics for increased productivity and reduced material handling costs.

Coil Lifting Magnets Products

Coil Lifting Magnets lift the coil peripheral from above or around, specifically designed for secure handling of coils in both horizontal and vertical configurations, effectively prevents any damage to the coil eye or side faces.

Electro Permanent Vertical Coil Lifting Magnets lift the cold steel coils in a vertical position (end face) , only contact the top of the coil, nearly no damage to coils while handling, particular useful for warehouse and service center.

Electro Permanent Vertical Coil Lifting Magnets also support the horizontal steel coil lifting, designed according to the curved surface, don’t need to check for wear and deformation of the coils caused by the use of mechanical means.

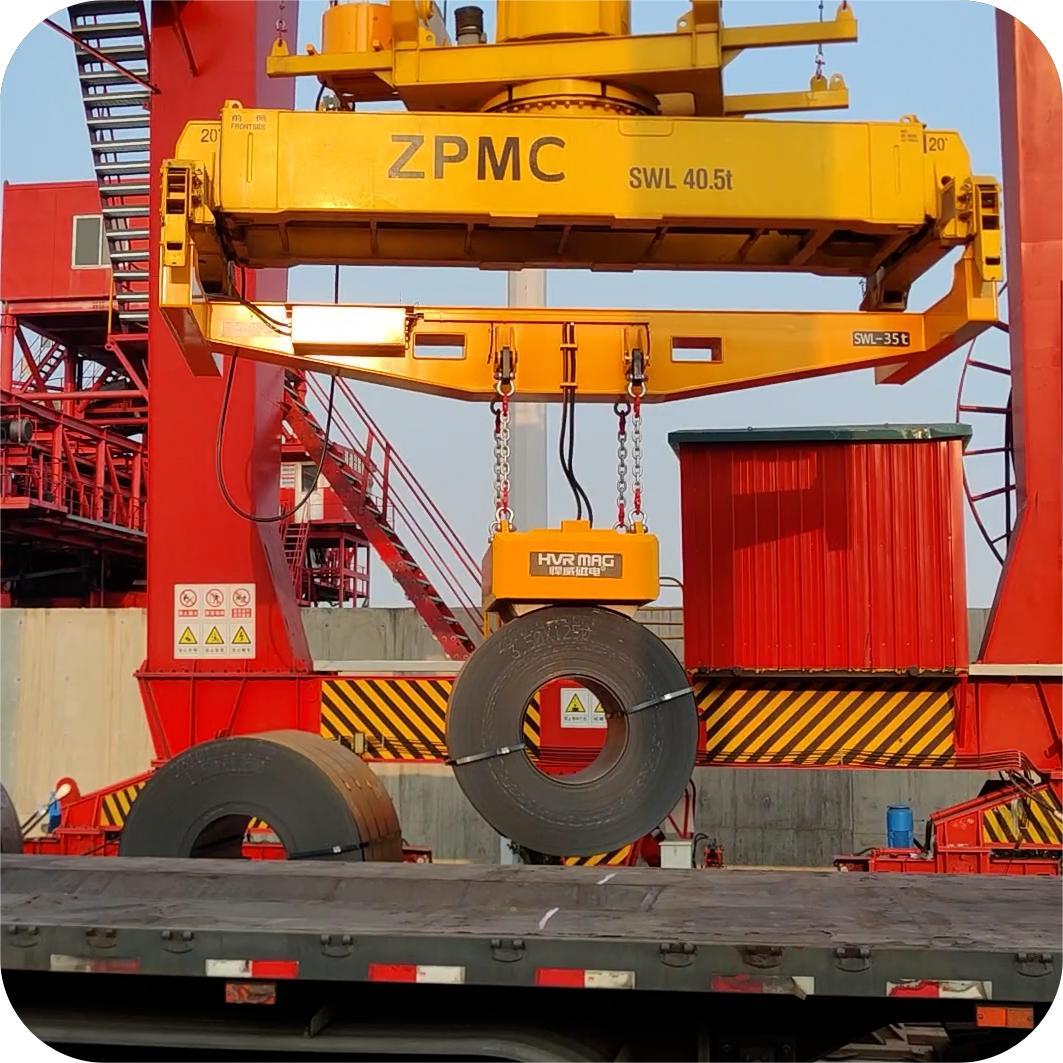

Coil Lifting Magnets Application

Coil Lifting Magnet, designed to optimize the handling and storage of steel coils.

They enable the safe and efficient transportation of coils within warehouses, facilitate dense vertical stacking to maximize space utilization, and expedite loading and unloading processes, thereby enhancing operational efficiency and reducing the risk of damage to the coils surface during storage and transit.

Coil Lifting Magnets, efficient and safe handling of coils during production, storage, and shipping.

These magnets ensure that steel coils are moved without manual intervention, reducing the risk of accidents and preserving the coils’ pristine condition. Their use is typical in automating the heavy lifting involved in steel manufacturing, thereby increasing productivity and safeguarding both the material and the workforce.

– Efficient Handling: Coil Lifting Magnets Efficiently move steel coils from production lines to storage or shipping areas

– Safety Enhancement: Coil Lifting Magnets minimize the risk of workplace injuries by reducing the need for manual lifting of heavy steel coils.

– Space Optimization: Coil Lifting Magnets optimize the storage of steel coils, allowing for dense stacking and reducing the required storage space.

– Cost Savings: Coil Lifting Magnets reduce labor costs and the potential for material damage, leading to cost savings in production and logistics.

– Quality Preservation: : Coil Lifting Magnet protect the surface of steel coils from scratches and dents, ensuring material quality for end-use applications.

Typically, there is 1-2mm of unevenness in the steel coils, and the thickness of the wrapping paper is usually around 2-3mm, so we need to attract the steel coils with a 5mm air gap. We can solve the problem by increasing the depth of permeability by adjusting the suction force of the electro-permanent magnets and increasing the number of layers of coils.

In the case of different thicknesses of steel coil products, will the adsorption of thin steel strip coil workpieces cause collateral adsorption? Suppose an electromagnetic lifter is used for handling. It is very likely to happen because the electromagnetic lifter cannot adjust its force in the transportation of thin steel coils, and it will cause collateral absorption of the workpiece.

In contrast, the electro-permanent coil lifting magnets do not, because its magnetic force is adjustable. Adjusting the appropriate magnetic force size will not cause a collateral impact on the workpiece below through the customer’s specialised needs.

The electro-permanent coil lifting magnets uses magnetic force to absorb the steel coil. The larger the contact surface of the workpiece, the greater the magnetic force.

The contact surface of the workpiece will have a curvature, which increases the difficulty of contact and will have a particular influence on the size of the magnetic force. The contact surface of the workpiece is kept at a good range, reducing the impact on the magnetic force size.

To fit the curvature of the workpiece, we can make the contact surface of the electro-permanent coil lifting magnets slightly curved, which will keep the contact surface of the electro-permanent coil lifting magnets with the workpiece in a good range and reduce the influence on the magnitude of the magnetic force.