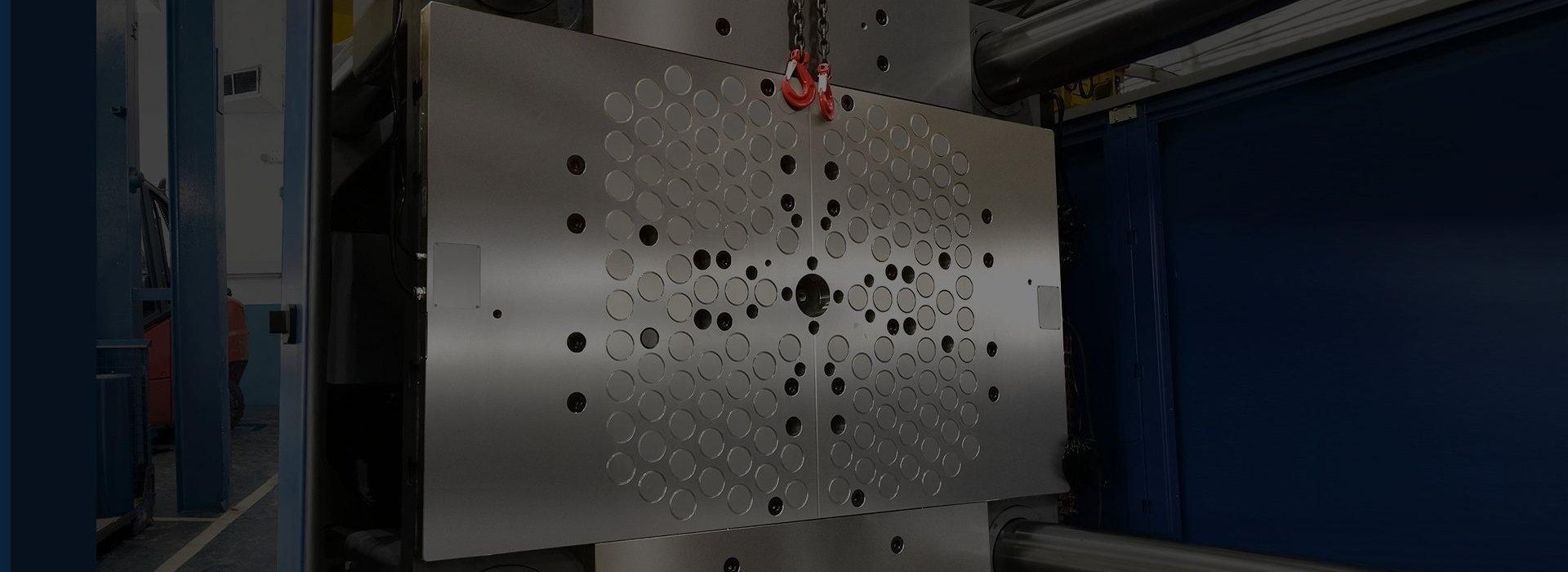

Magnetic Quick Mold Change System

HVR MAG Magnetic Quick Mold Change System utilizes electro permanent magnetic technology, to clamp molds and dies on injection molding machines and stamping machines.This magnetic mold clamp supports quick mold changeover. Mold Change, 3 Minutes Done.

What is Magnetic Quick Mold Change System?

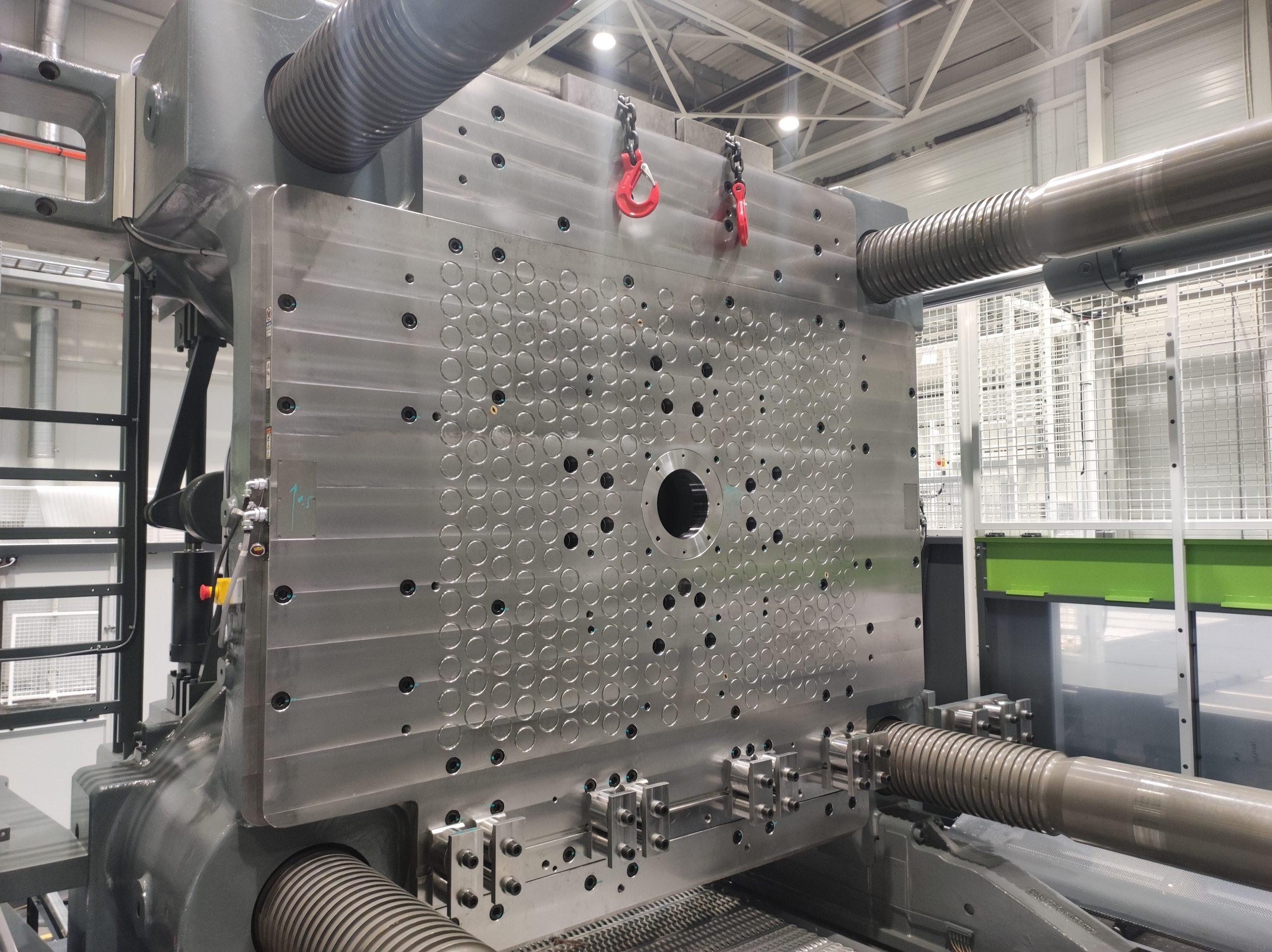

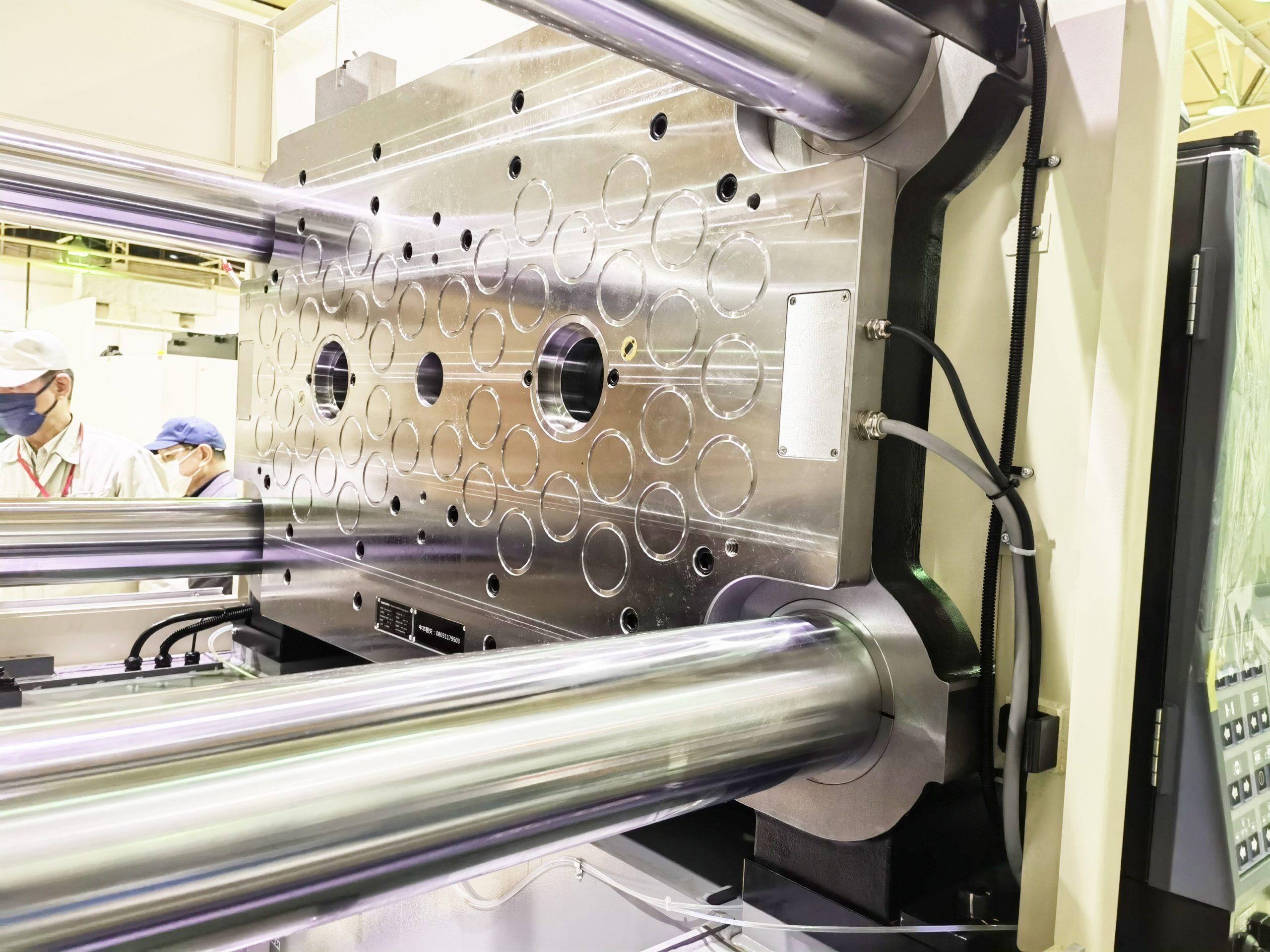

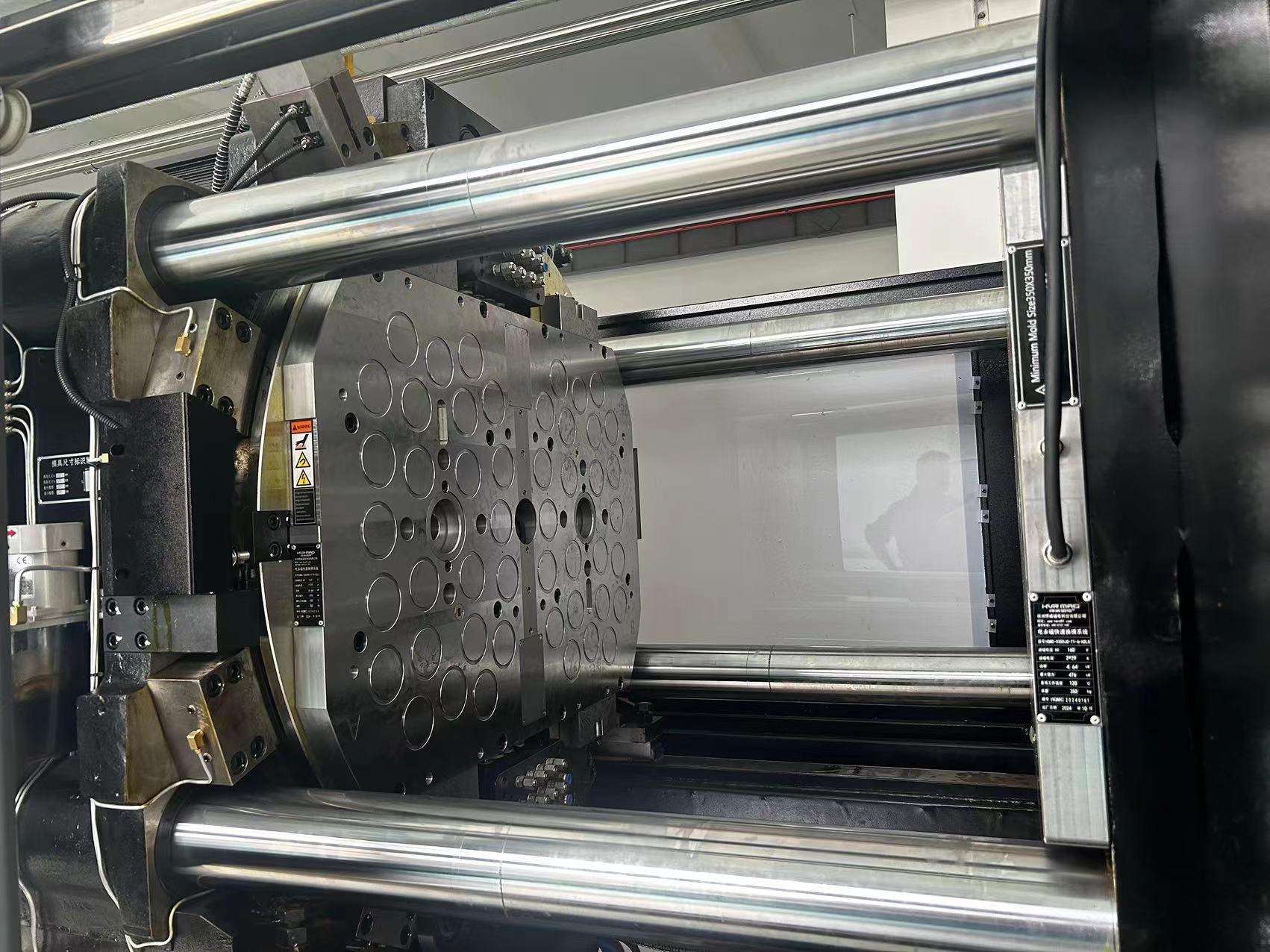

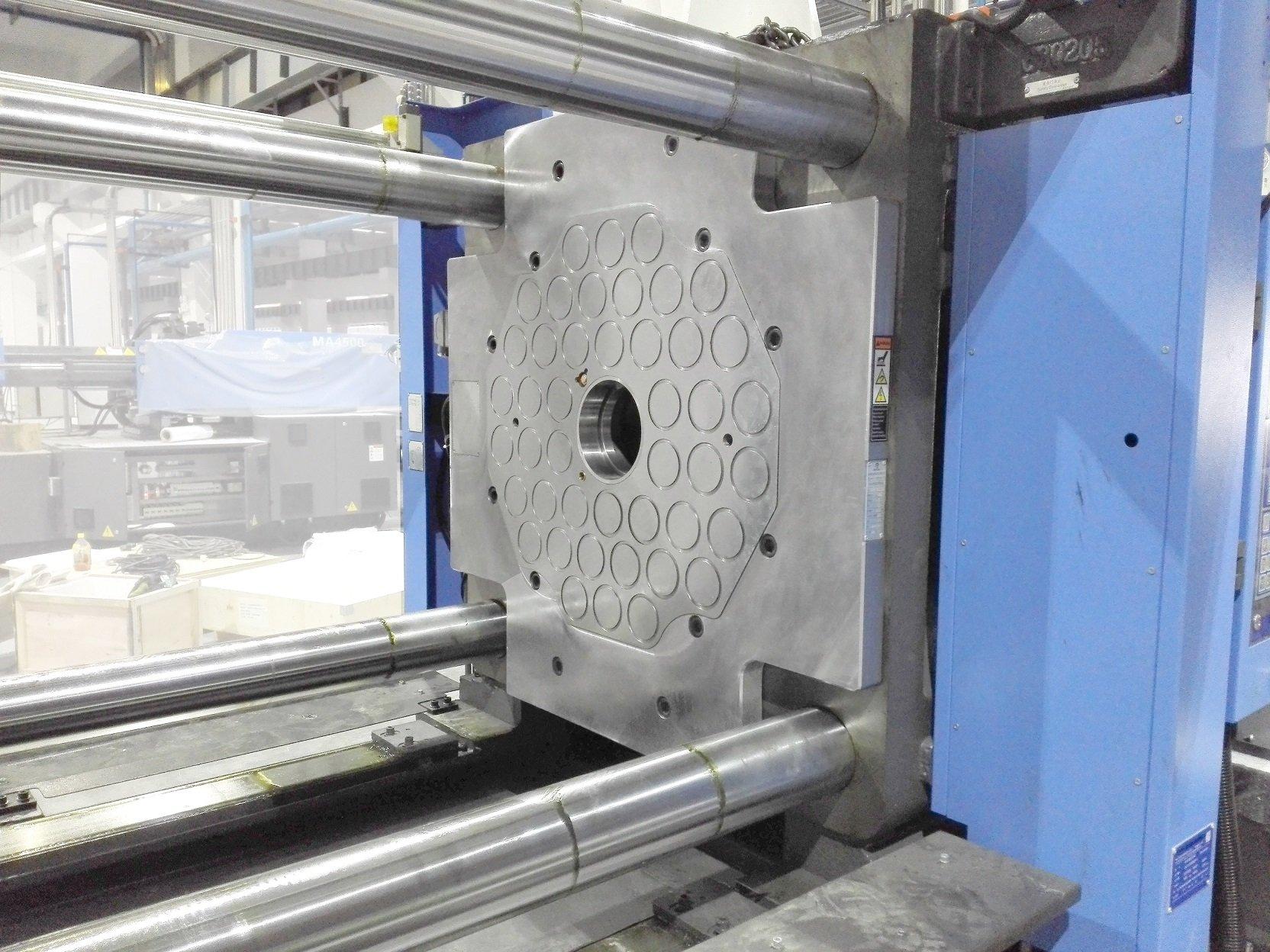

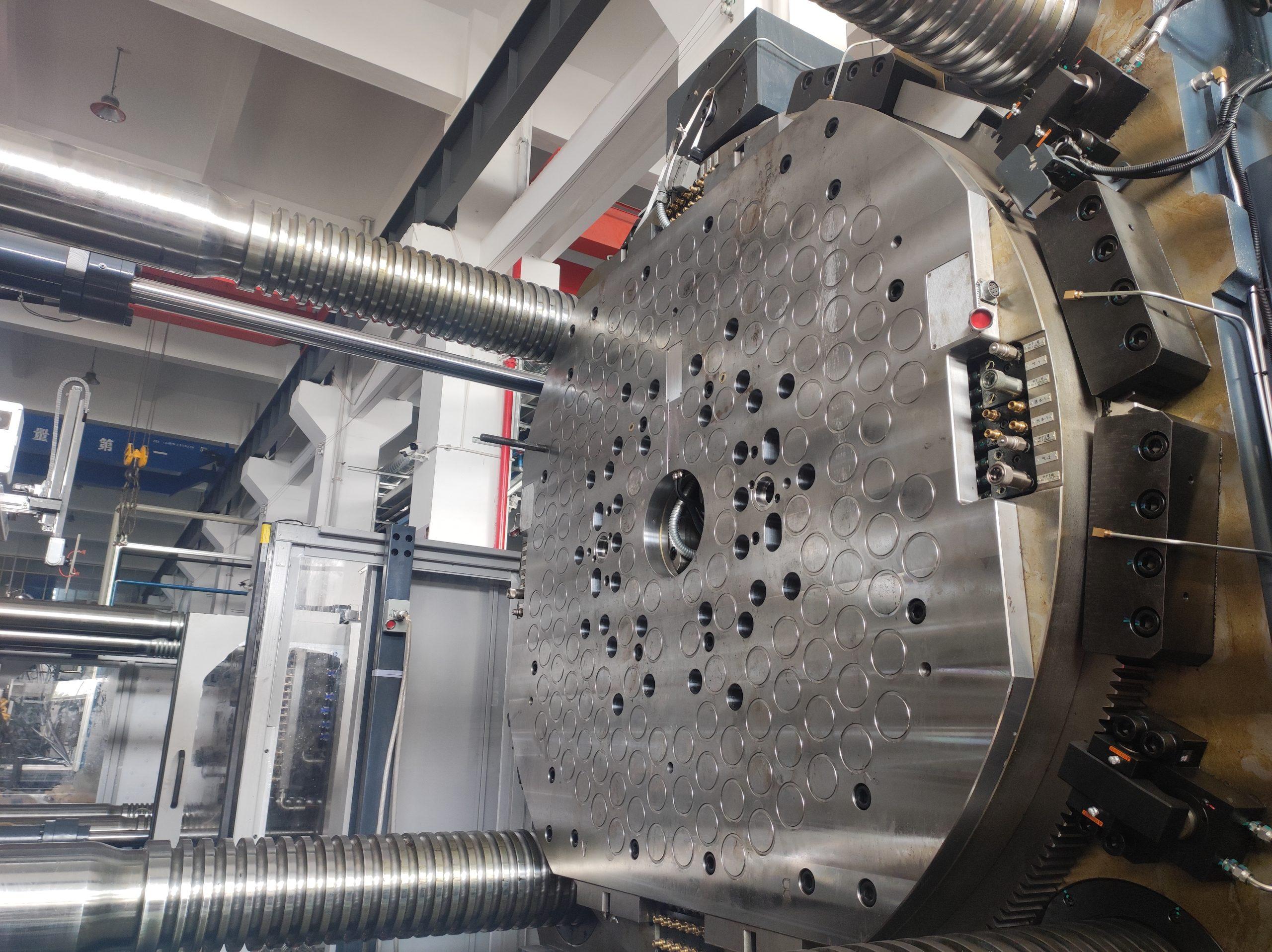

HVR magnetic quick mold change system consists of 2 magnetic platens, fixed and stationary, human-machine interface, electric control cabinet. The size and shape of magnetic platens can be custom designed.

Magnetic quick mold change system is suitable for 50-4000ton injection molding machine. The magnetic platen provides uniform and strong clamping force on mold contact surface. The electro permanent magnetic field can be activated and deactivated rapidly, so the mold can be easily clamped and unclamped. It is also able for one single operator to perform the operation safely outside the machine.

8 Safe Measures of HMQC System

HVR Quick Mold Change System features 8 safety precaution attributes that make it particularly safe.

MAG/DEMAG starts only when mold is fully pressed and in contact with magnetic platens.

MAG/DEMAG is allowed only when magnetic flux meets safety threshold.

The system stops automatically if magnetic platens exceed the set temperature limit.

MAG/DEMAG is confirmed only when the required current pulse is detected.

If mold shifts during production, the injection machine stops immediately.

DEMAG only occurs if mold-to-platen gap is under 0.2mm; larger gaps halt production.

Production starts only when all sensors are normal and both sides are magnetized.

The key selects setup or production mode; DEMAG is disabled during production.

Magnetic Quick Mold Change System Feature

More than safety.

90% reduction in mold changeover time

40% Labor cost save with magnetic clamping force

Faster mold changes mean more production cycles per day

Low Power Consumption during working

Reduces the risk of injuries associated with manual clamping systems

Designed for durability and longevity, ensuring a long service life with minimal upkeep

Fewer moving parts mean less wear and tear, leading to lower maintenance costs

Reducing downtime during maintenance

3 Min Mold Change Process

- Lifting mold into injection machine.

- Align with the locating ring adjust position and close the mold.

- Doing MAG operation for fixed and movable side magnetic platens.

- Unlock mold from lifting equipment, remove hoisting gear, then injection machine could normally work.

- Close the mold and add lifting chain.

- Doing the DEMAG operation for fixed side and movable side magnetic platens.

- Machine’s movable platen return back, start to remove the mold.

- Mold remove operation finish, injection machine Standby.

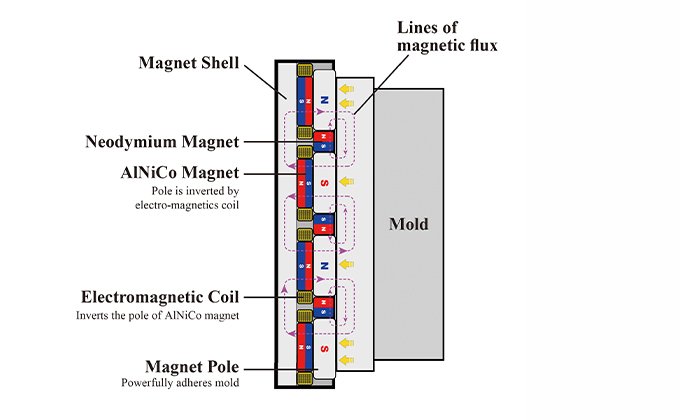

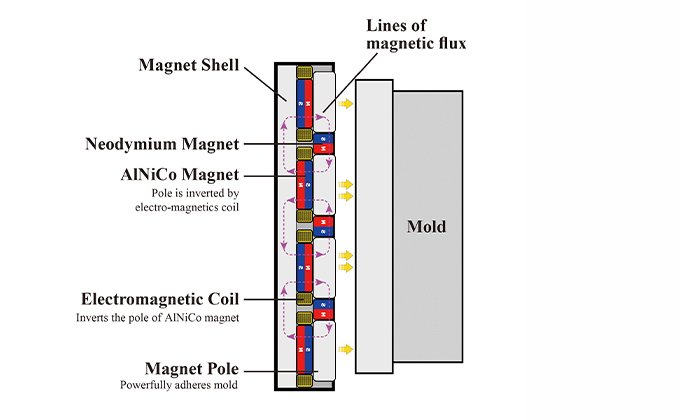

Working Principle of Magnetic Quick Mold Change System

- An excitation current is passed through the solenoid coil for 0.1-0.5s.

- Pole of AlNiCo magnet is inverted. Neodymium magnet and AlNiCo magnet become unipolar.

- The magnetic poles form a magnetic circuit with the mold and clamping the mold.

- An excitation current is passed through the solenoid coil for 0.1-0.5s.

- Pole of AlNiCo magnet is inverted.

- Magnetic Flux of Neodymium magnet and Alnico magnet is not emitted from the surface of the magnet core. Thus, it unclamps the mold.

Traditional Clamping System VS Magnetic Quick Mold Change System

| Contents | Mechanical System | Hydraulic Systems | Magnetic Clamping |

| Safety | Unable to stop the press if fault occurs. | Unable to stop the press if fault occurs. When power is down, hydraulic presser will be decreased and cause accident. | Multiple sensors monitor the system for faults. No energy consumption during working phase. |

| Reliability | Serious potential safety hazard, causing by mechanical clamping. | Oil leaks, pipe blockage, part replacement. High cost and time consuming. No feedback signal. | No Movable part and no electrical power needed once energized. Real time feedback signal during working process. Multiple sensors monitor the system for faults. |

| Efficiency | Long mold change cycle, low efficiency. | Limitation of thickness of mold base board, it causes much less efficient mold change time. | Reduces mold change over times (up to 90%). A single operator easily and safely performs the operation. |

| Clamping Fore | Clamping force only available in mold peripheral location with very limited. No clamping force on mold center area. Mold is easy to deform. | Clamping force around the peripheral edge of the mold. No clamping force on mold center. | Uniform clamping over the entire surface, especially the center of the mold back. Ensure the working process of mold clamping rigidity. |

| Quality | Due to deformation of clamping pressure and no clamping force in the center of mold back. The consistency of product is not good. | Due to deformation of clamping pressure and no clamping force in the center of mold back. The consistency of product is not good. | Clamping the mold with uniformity allows obtaining good quality parts even with the first molds. The two mold halves are perfectly aligned: friction is minimized, preserving wear of molds and the machine. |

| Flexibility | Low suitability. | All the mold should require fixed size and shape. | The entire magnetic working area allows any mold size and shape. No modification required. |

| Economic | Pressing plate and bolt always needs replace, huge labor cost. | Pressing plate and bolt always needs replace, huge labor cost. | No moving part, No wearing part. No maintenance need. |

Component of Magnetic Quick Mold Change System

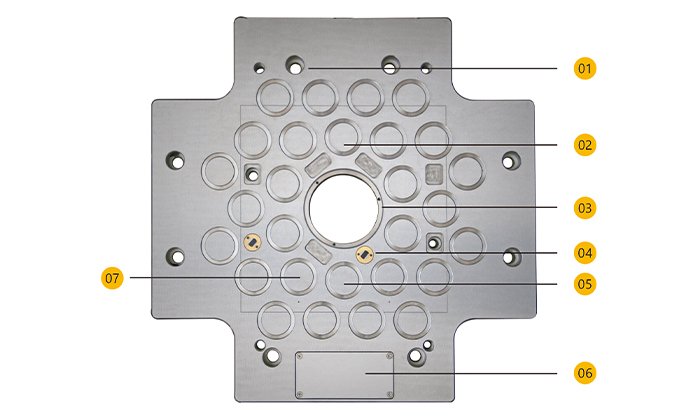

- Fixed Magnetic Platen

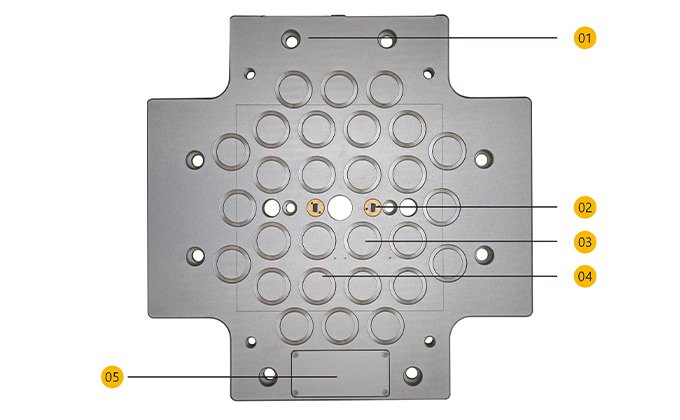

- Movable Magnetic Platen

- Electric Control Cabinet

- HMI Type HQMC-11A

1. Mounting screw hole

2. Temperature detection

3. Locating ring

4. Distance detection

5. Magnetic flux detection

6. Junction box

7. Mold dislocation detection

1. Mounting screw hole

2. Distance detection

3. Mold dislocation detection

4. Magnetic flux detection

5. Junction box

1. Accurate control

2. Intelligent monitoring

3. Strong stability

4. Good compatibility

1. Full-metal pushbutton with good controllability and high protection level.

2. More stable, suitable and safer for industrial application.

3. Easy to learn and operate.

4. Fault messages are displayed directly.

This system is designed to overcome the friction during the ejection process and the weight of the mold by magnetically clamping the back plate of the mold, preventing it from falling out of the machine. Key parameters include:

- Weight of the mold.

- Maximum opening force of the injection molding machine.

- Clamping force of the movable side. It is greater than that of the fixed side due to acceleration, so it will be prioritized.

- Branch and model of the molding machine.

- Mold clamping force (Unit: TON).

- Drawings of the machine clamping plates and dimensions of the centering ring.

- Minimum mold size.

- Maximum mold weight (fixed and movable sides).

- Maximum mold contact temperature.

No. The system does not rely on continuous electricity. Once activated, it won’t demagnetize when it’s powered off.

No. The system only requires current during the mold change, and the magnetic field extends only 20 mm from the surface of the magnetic platen. All other areas are non-magnetic, ensuring no interference with the injection molding machine.

No. After magnetization, the system forms a closed magnetic field on the surface of the magnetic platen. The effective range of the magnetic field lines is 20 mm. Beyond 20 mm, the magnetic field becomes very weak and comparable to the ambient magnetic field. However, people with pacemakers, bank cards, watches, and cell phones should not get closer than 20 mm to the magnetic field.

Yes. The platen is designed with a multi-layer, waterproof, anti-oil, and corrosion-resistant structure. It is possible in water, oil, and gas environments.

Yes. There are available in high temperature resistant versions. However, we do not recommend using the magnetic clamping plates at temperatures above 180°C.

If the back plate temperature exceeds the allowed limit, an alarm is triggered, and the automatic production process stops immediately. To resolve this, place an insulation plate between the back plate of the mold and the molding plate.

No if the insulation plate is on the back plate. However, it is possible if the insulation plate is between the back plate and the molding plate.

The magnetic quick mold change system has a 30% safety margin. For example, if 20% of the back plate is holes, the system is still safe. However, it is worth noticing that other factors, such as the flatness of the back plate, also affect the total attraction force of the magnetic plate.

Yes. The magnetic platen must fit perfectly against the magnetic clamping surface.

Improper adjustment can cause the mold to be pushed off the magnetic plate. It’d be better to avoid making the injection nozzle head go too deep, and use a safety chain during the start-up phase.

Yes. If it opens too quickly, especially in the first phase, a vacuum effect may occur, pulling the mold off the magnetic plate.

In this case, increase the opening force. When the opening force exceeds the clamping force of the magnetic platen, the mold will be released. A proximity switch will trigger an alarm and stop the machine immediately. Please take precautions to prevent the mold from falling, such as using a safety chain.

无字幕_10506-e1749461799641.jpg)