The wind power industry is developing faster and faster.

According to the Global Wind Energy Council (GWEC), global installed capacity is expected to reach 130 gigawatts by 2024, increasing by approximately 158 gigawatts on average each year over the next five years.

Long – term goal: To meet the target of doubling global renewable energy capacity by 2030 and limiting global warming to 1.5 °C, as the 28th United Nations Climate Change Conference (COP28) adopted, the wind power industry must increase its annual installed capacity to at least 320 gigawatts by 2030.

So, what is the application prospect of electric permanent magnets in wind power equipment manufacturing?

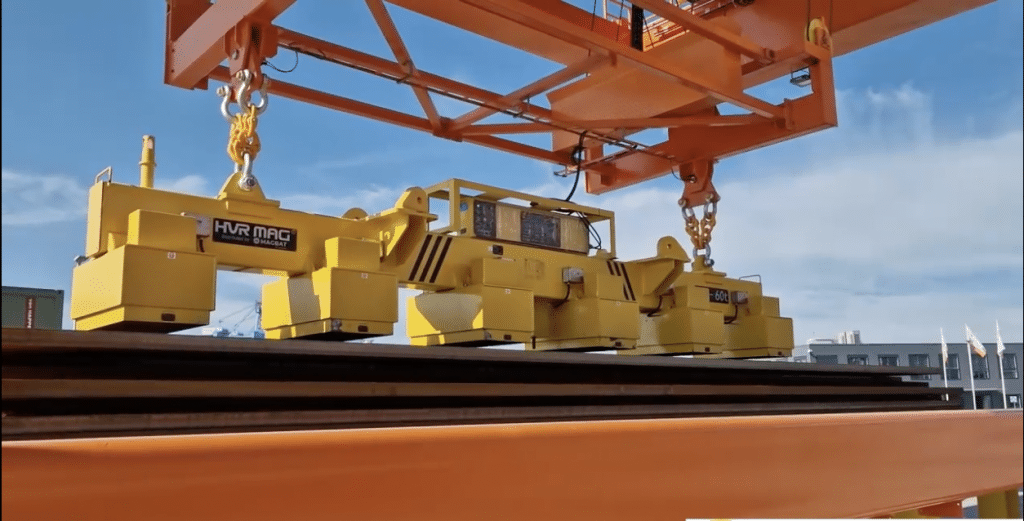

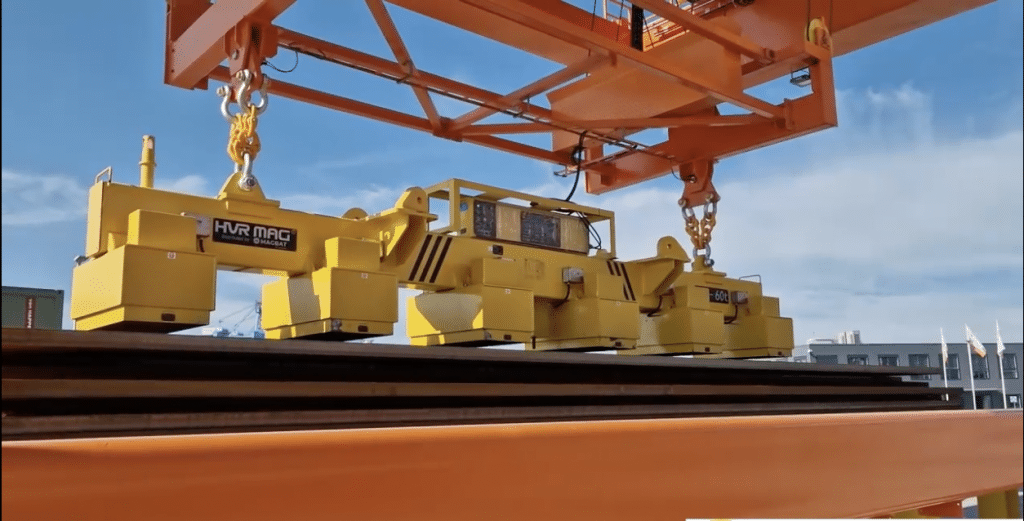

The components of wind power generation equipment, such as blades, towers, and engine rooms, are large in volume and heavy in weight. Traditional handling methods not only prove inefficient but also pose safety hazards. Electric permanent magnets can quickly and firmly attach to these components. This enables workers to handle and transfer them conveniently in the production workshop. As a result, handling efficiency improves, labor costs go down, and operational risks reduce. For example, in blade production workshops, workers can use electric permanent magnets to easily lift newly produced blades out of molds and transport them to designated locations.

During component assembly, precise positioning and stable fixation are essential. Workers can utilize electropermanent lifting magnets to handle blades, tower sections, and the like. These magnets help keep these components stable when joining them with other parts, ensuring installation accuracy and quality.

Our Customers can rely on HVRMAG for innovative and dependable solutions that enhance their operational efficiency. Our extensive network and our commitment to sustainability and corporate social responsibility drive us to stay at the forefront of technological advancement. We strive to continuously improve and offer the best, ensuring that we lead in the field through our efforts and dedication.Visti for more.

Our Customers can rely on HVRMAG for innovative and dependable solutions that enhance their operational efficiency. Our extensive network and our commitment to sustainability and corporate social responsibility drive us to stay at the forefront of technological advancement. We strive to continuously improve and offer the best, ensuring that we lead in the field through our efforts and dedication.Visti for more.

Our Customers can rely on HVRMAG for innovative and dependable solutions that enhance their operational efficiency. Our extensive network and our commitment to sustainability and corporate social responsibility drive us to stay at the forefront of technological advancement. We strive to continuously improve and offer the best, ensuring that we lead in the field through our efforts and dedication.Visti for more.

Our Customers can rely on HVRMAG for innovative and dependable solutions that enhance their operational efficiency. Our extensive network and our commitment to sustainability and corporate social responsibility drive us to stay at the forefront of technological advancement. We strive to continuously improve and offer the best, ensuring that we lead in the field through our efforts and dedication.Visti for more.