In metallurgy production, machining large components between 200-660mm diameter presents unique challenges. Traditional mechanical clamping methods simply can’t keep up with the demanding precision requirements of modern bearing manufacturing. Workers previously wasted valuable production time tightening numerous screws on conventional fixtures, while uneven clamping pressure often compromised the critical tolerances needed for high-performance bearings.

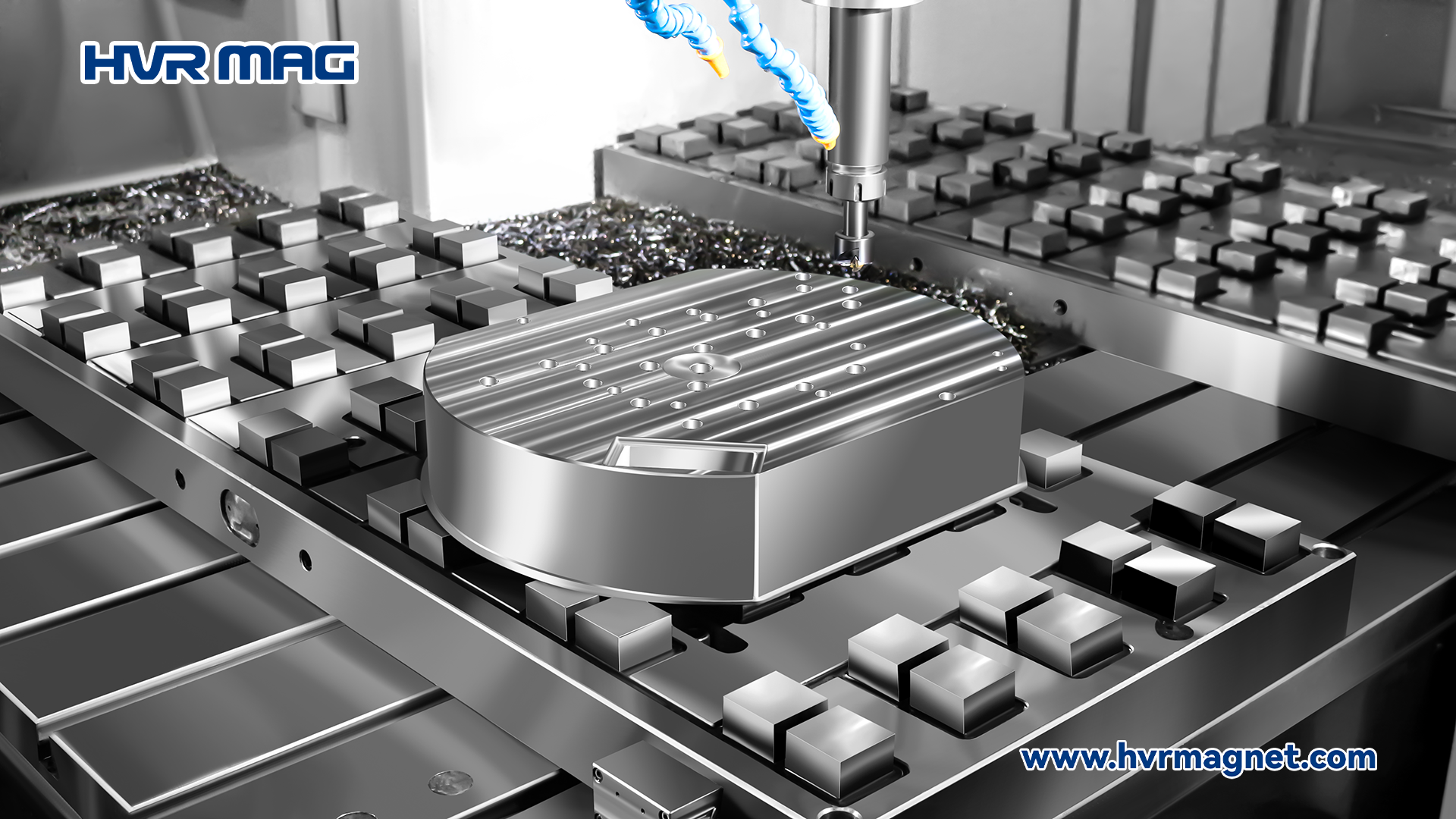

HVR MAG’s magnetic chuck transforms this process completely. Specifically designed for metallurgy applications, this innovative solution delivers 16kg/cm² holding force across its entire 188-660mm diameter working surface. Metallurgical manufacturers particularly appreciate how the magnetic chuck secures bearing components in under 2 seconds – a game-changing improvement over traditional methods that required minutes of manual clamping. The full-surface magnetic adhesion ensures perfectly uniform pressure distribution, eliminating the distortion risks associated with point-clamping methods.

For metallurgy workshops, the benefits extend far beyond faster cycle times. The chuck’s permanent magnet technology provides failsafe operation without continuous power requirements – a critical safety advantage when working with heavy bearing components. Operators simply press a button to engage or release workpieces, significantly reducing physical strain during long production runs. More importantly, the consistent, vibration-free clamping improves surface finish quality and dimensional accuracy – two factors that directly impact bearing performance and longevity.

Leading bearing manufacturers report measurable improvements since adopting this technology. One producer reduced bearing raceway machining time by 40% while achieving superior roundness specifications. It also eliminated all workpiece slippage incidents during heavy cutting operations. The magnetic chuck’s reliability and precision make it particularly valuable for machining specialty alloys used in advanced metallurgical applications.

HVR MAG continues to develop magnetic solutions tailored for the metallurgy industry’s evolving needs. Our technology helps bearing manufacturers achieve new levels of productivity while maintaining the strict quality standards required in this demanding sector.