Hold workpiece securely is vital for milling. Good clamping ensures high accuracy. It also improves operator safety. Many workshops use traditional methods. But these often waste time.

Tools to Hold Workpiece

Firstly, let us discuss common holding techniques. Many factories use manual clamps. Others rely on custom fixtures. These methods require tightening bolts. Workers spend minutes on each part. This slows down production. So, efficiency drops significantly.

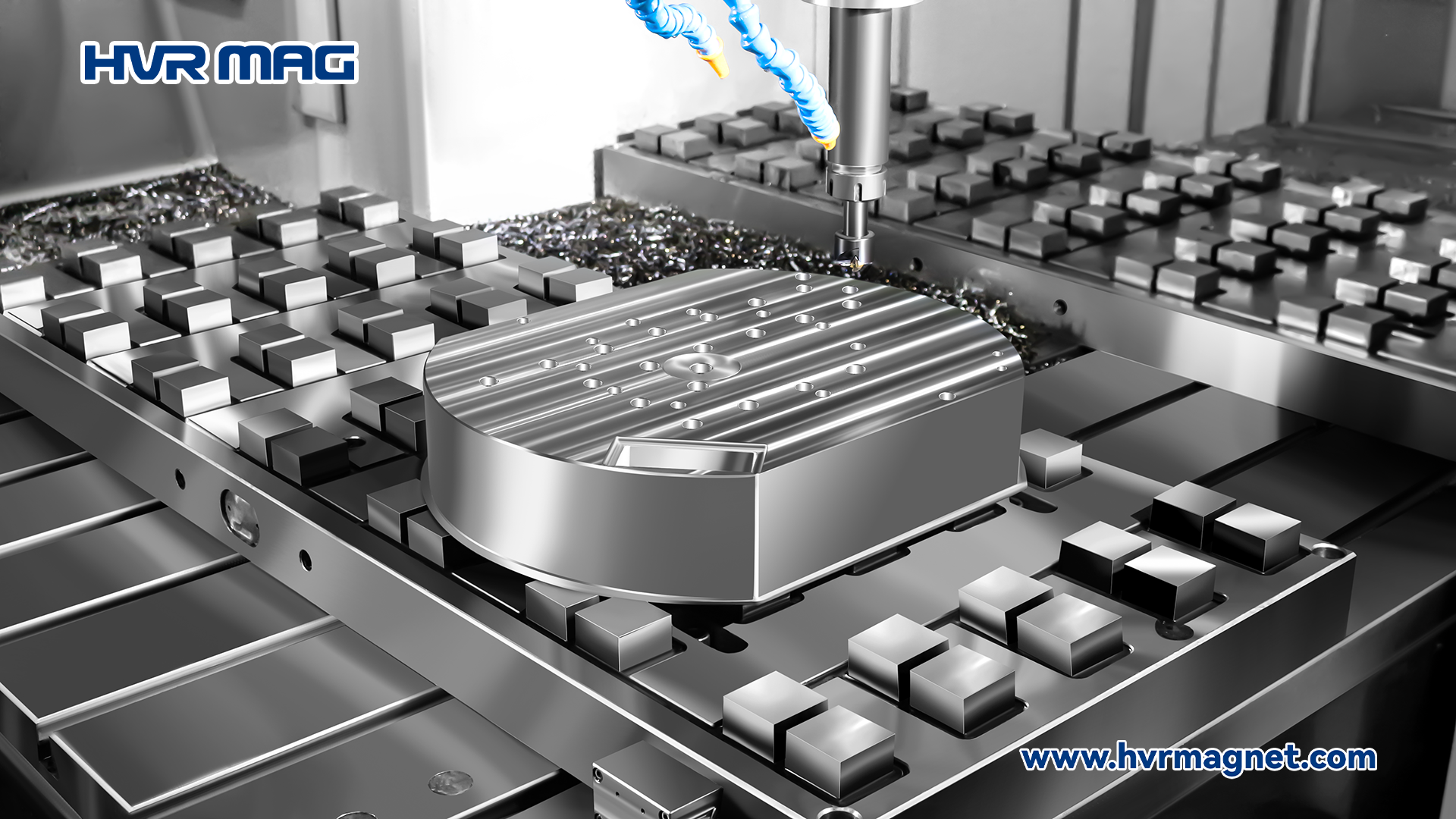

Magnetic Chuck to Hold Workpiece

However, new solutions now exist. Electro-permanent magnetic chucks offer a better way. They use strong magnetic force. For example, they can provide over 16kg/cm² suction. This force holds the workpiece firmly. Thus, no screws are needed.

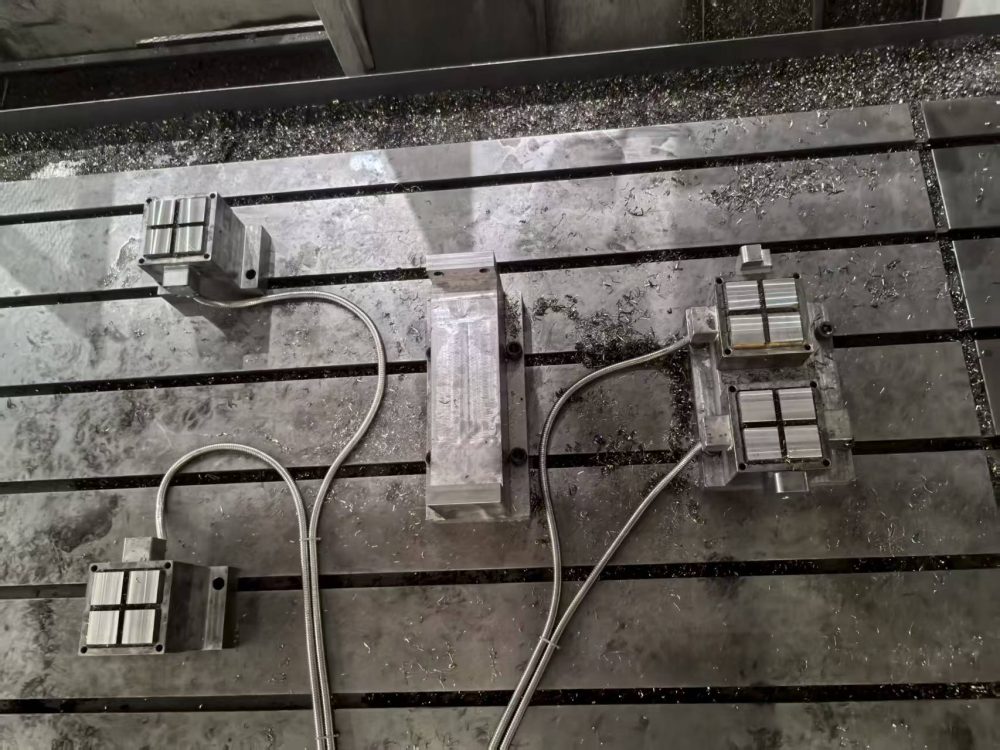

Moreover, consider a real case. A CNC machine tool company faced this issue. They used homemade fixtures before. Each setup took too long. Their main need was faster clamping. Therefore, they tried an innovative solution.

Specifically, they used four electro-permanent magnetic chucks. These devices held gray cast iron parts. The milling allowance was 1mm. The application was on a gantry machining column. After switching, they saw great results.

Hold Workpiece and Save 5 Minutes per Setup

Consequently, each workpiece saved five minutes. The total clamping time dropped sharply. Additionally, machining precision improved. Repeated tests met all accuracy standards. This shows a clear technical breakthrough.

Furthermore, this method cuts costs. It reduces labor time. It also minimizes human error. So, workshops can boost output. In summary, magnetic holding solves key problems.

In Conclusion

Proper workpiece holding matters a lot. Traditional ways delay work. Modern magnetic chucks speed it up. They ensure precision and save money. Therefore, consider upgrading your clamping method today. Your milling process will thank you.