Producing plastic automative parts requires high efficiency. Quick mold changes are essential. However, traditional methods often cause delays, many factories face this challenge daily. Workers used manual locking systems before, the way slow and unsafe. Moreover, skilled workers were hard to find, which increased costs and stress.

Magnetic Solution for Plastic Automative Parts Fabrication

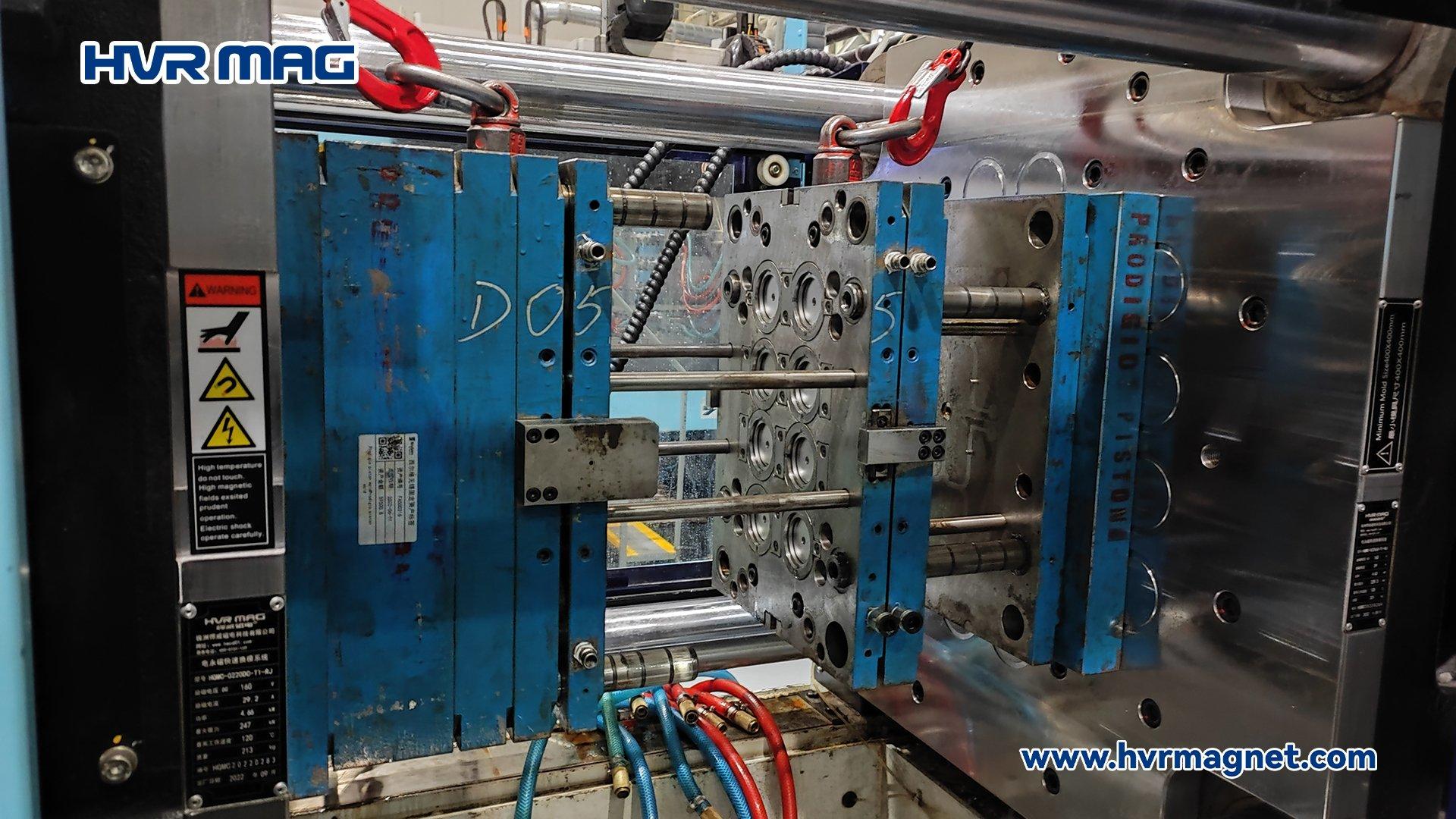

Now, a new solution exists. Electric permanent magnet systems enable fast mold changes. For example, a Shandong Auto Tech company adopted this technology. They upgraded their 380T injection molding machine. Their goal was to boost productivity.

They also tried magnetic plates from another company, and this time they choose to trust HVR MAG, a leading company in magnet industry in China and has international brand.

HVR MAG we customized the HQMC-380C-T2-1 model for the plastic automative parts manufacturer. It withstands high temperatures up to 150 degrees. Therefore, it suits demanding production environments. Operators find it very simple to use, only need minimal training to handle it.

Successfully Change Mold in 3 min

After installation, results were impressive. Mold change time dropped to just three minutes. Consequently, production line efficiency soared, workers felt less physical strain. In addition, companies saved on labor costs.

This progress benefits the entire plastic automative parts industry. Fast mold change systems reduce downtime significantly. They also improve workplace safety. Furthermore, production output increases dramatically.

Many manufacturers now consider this upgrade. It addresses key industry pains effectively. For instance, it solves slow changeover and high labor intensity, and then factories gain a competitive edge.

In Summary

Electric permanent magnet technology transforms mold changing. It makes plastic automative parts fabrication faster and smarter. Companies should try and adopt this innovation for better results and high ROI.