In today’s automated manufacturing environments, efficiency and reliability are paramount. Electro-permanent magnetic workholding technology has emerged as a valuable solution for addressing these needs, particularly in applications requiring rapid cycling and consistent performance. This technology operates on principles that make it especially suitable for integration into automated systems and robotic work cells.

Technical Foundation and Operational Advantages

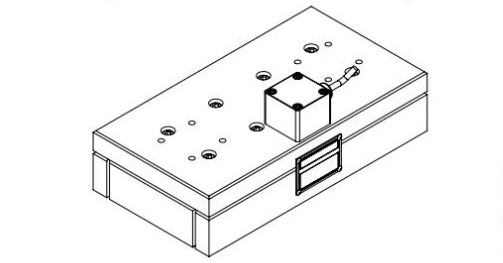

Electro-permanent magnet technology utilizes brief electrical pulses to switch magnetic states, creating a secure holding force without continuous power consumption. This characteristic provides inherent safety advantages while reducing energy requirements. The instant engagement capability allows for rapid workpiece changes, significantly reducing non-productive time between operations. The system’s consistent holding pressure across the entire contact surface ensures uniform support, minimizing vibration and improving machining accuracy.

Integration with Robotic Systems

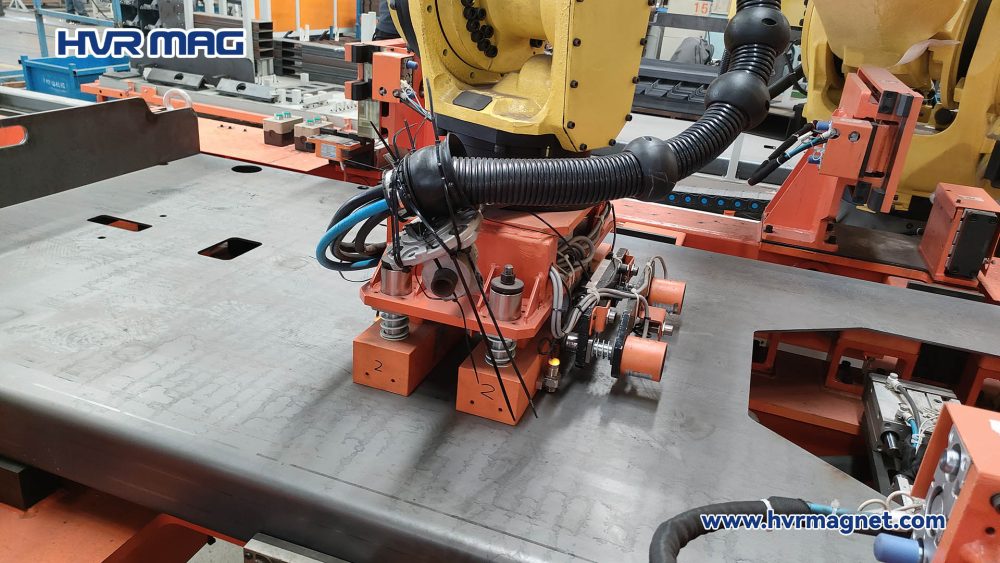

The compatibility of magnetic workholding with robotic automation represents one of its most significant benefits. Robotic arms equipped with magnetic end-effectors can handle various ferromagnetic materials without mechanical adjustments or tool changes. This flexibility is particularly valuable in mixed-production environments where workpiece sizes and shapes may vary. The simple interface requirements facilitate straightforward integration with existing automation controls, while the lightweight design minimizes the impact on robot payload capacity.

Application Versatility in Industrial Settings

This technology demonstrates considerable adaptability across different manufacturing sectors. In machining operations, it securely holds workpieces for milling, drilling, and grinding processes. The automotive industry utilizes these systems for handling stamped components and structural parts. Metal service centers employ magnetic workholding for sorting and transferring sheet materials. The non-marking holding method preserves surface quality, making it suitable for finished or coated materials where surface protection is crucial.

Practical Implementation Considerations

Successful implementation requires attention to several technical parameters. The magnetic system must be appropriately sized according to the application requirements, considering factors such as workpiece weight, material composition, and surface conditions. Safety systems, including backup power supplies and status monitoring, ensure reliable operation in production environments. The maintenance requirements are generally minimal, primarily involving periodic checks of electrical connections and wearing surfaces.

Future Development Directions

Current advancements in magnetic workholding focus on enhancing intelligence and connectivity. Integrated sensors can provide real-time feedback on workpiece presence and positioning, while programmable magnetic zones offer additional flexibility for irregular shapes. These developments align with Industry 4.0 initiatives, supporting the trend toward more adaptive and data-driven manufacturing systems.

The continued evolution of magnetic workholding technology demonstrates its growing importance in automated manufacturing. By providing reliable, efficient, and versatile workpiece handling solutions, these systems contribute to enhanced productivity and operational flexibility in modern industrial settings.