In this case, HVR MAG, as a manufacturer of electro-permanent magnets, provided a magnetic gripper solution for an automated production line at a forklift manufacturing plant. The customer produces forklifts and related components, including fuel tanks and other steel workpieces, with individual part weights of up to 200 kg.

The main task in this application is material loading and unloading. Electro-permanent magnetic grippers work together with an automated robotic arm to move raw parts into the production process and transfer finished components out of the line. The solution replaces the customer’s previous method, which relied on manual operation using an overhead crane for lifting, positioning, and assembly.

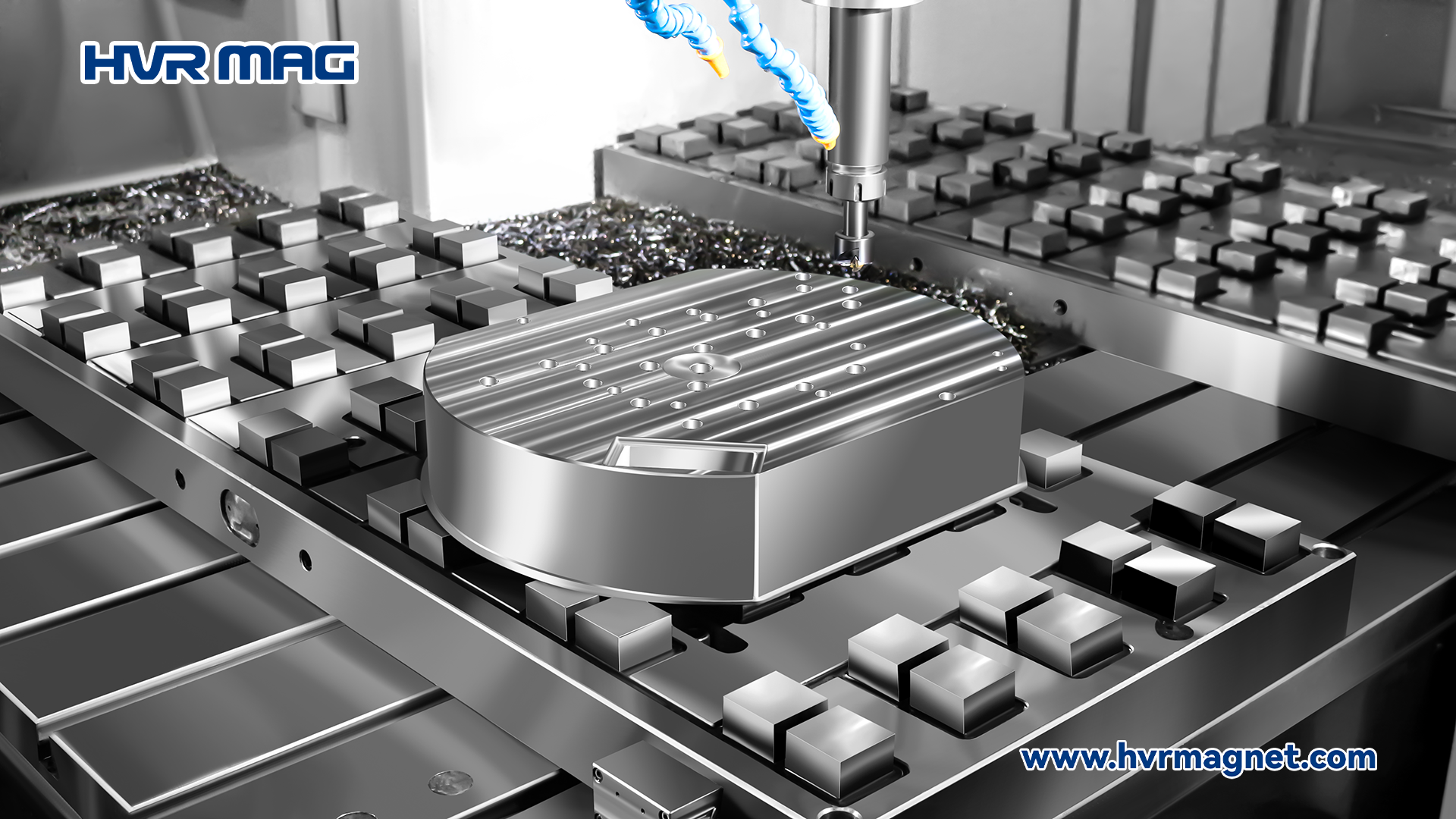

For this project, we designed a customized system using two HEPMP-1814A-GW electro-permanent magnets working together. The magnetic gripper system integrates with the robotic arm and control system, allowing stable and repeatable handling of different workpieces. The solution supports a wide range of part sizes and thicknesses without mechanical adjustments.

Compared with the original lifting tooling, the magnetic gripper brings several practical improvements. First, when lifting single steel plates or components, the electro-permanent magnetic gripper allows faster and simpler handling. Operators no longer need to pry plates apart or install mechanical clamps. Positioning becomes quicker, which improves overall efficiency and significantly reduces labor intensity.

Second, the magnetic gripper adapts well to workpieces of different sizes and thicknesses. Through control grouping, the system ensures that only one steel plate or component is lifted at a time, even when handling materials with varying specifications. This improves process stability and reduces handling errors.

Third, the magnetic gripper holds the workpiece by magnetic force acting on the surface. This non-contact gripping method helps avoid scratches, clamp marks, or deformation that can occur with traditional mechanical fixtures. As a result, the surface quality of the workpieces remains consistent throughout the handling process.

By combining electro-permanent magnetic grippers with automated handling equipment, the customer reduced manual labor, lowered the risk of workplace injuries, and improved production flow. After implementation, overall production capacity increased by more than three times compared with the previous manual crane-based operation.

This project demonstrates how a magnetic gripper solution can support efficient, safe, and flexible automation in forklift manufacturing and similar heavy industrial applications.