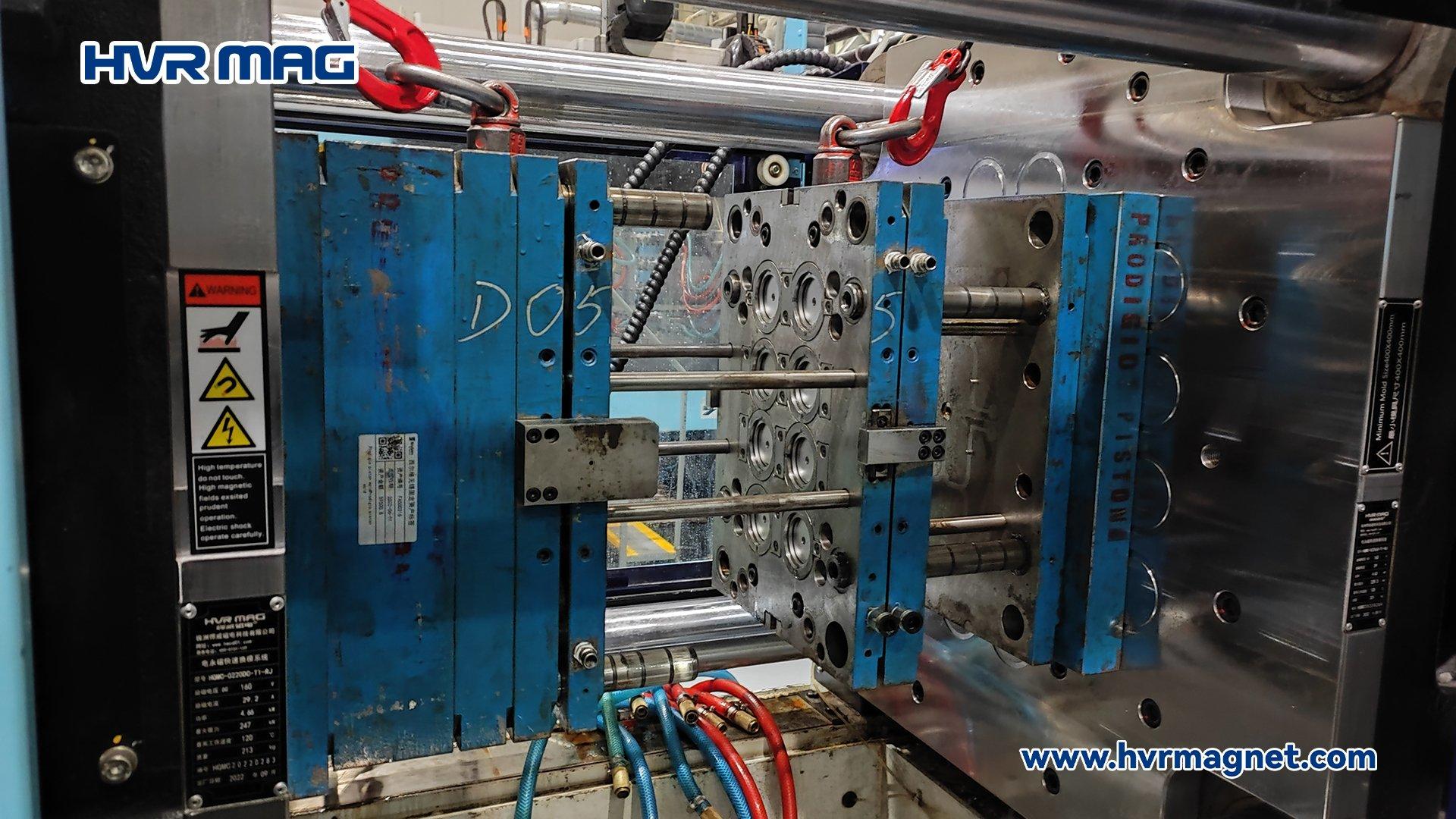

Efficiency defines success in the modern plastic injection industry. Recently, A plastic products manufacturer successfully transformed its production line using the Injection Magnetic Platen system. This case study highlights how HVR MAG technology solves traditional manufacturing bottlenecks.

Faults of Manually Mold Change

Before the upgrade, the manufacturer relied on manual bridge clamps for their 200T injection molding machines. This traditional method created several operational hurdles. Large molds required significant time to align and secure manually. Consequently, the staff faced high labor intensity and frequent production delays.

Furthermore, manual clamping poses safety risks and limits overall output. To address these challenges, the company sought a solution to reduce costs and simplify the mold-changing process. They chose the HQMC-0200A-T1-1 Injection Magnetic Platen, which features a 120-degree temperature resistance.

Why Choose an Injection Magnetic Platen?

The HVR MAG Electro Permanent Magnetic Quick Mold Change System offers distinct advantages over mechanical systems. First, it utilizes permanent magnets to hold the mold securely. Electricity only flows during the brief magnetization and demagnetization phases. Therefore, the system remains safe even during a total power failure.

Additionally, the EPM Magnetic Platen provides uniform clamping force across the entire mold surface. This prevents mold deformation and extends the life of your machinery. Because there are no moving parts or bolts, maintenance requirements stay remarkably low.

Succeed Results of Injection Magnetic Platen

The transition to the magnetic system yielded immediate benefits for the customer.

- Faster Changeovers: The company significantly increased its mold-switching speed.

- Reduced Labor: Operators no longer need specialized mechanical skills to handle the equipment.

- Higher Profits: Faster production cycles directly improved the company’s total revenue.

- Cost Savings: Lower labor intensity and faster turnaround times reduced operational overhead.

Conclusion

In conclusion, the Injection Magnetic Platen is a vital tool for competitive plastic manufacturers. It turns a complex, dangerous task into a simple, push-button operation. If you want to optimize your 200T injection molding machine, this technology provides the perfect ROI.