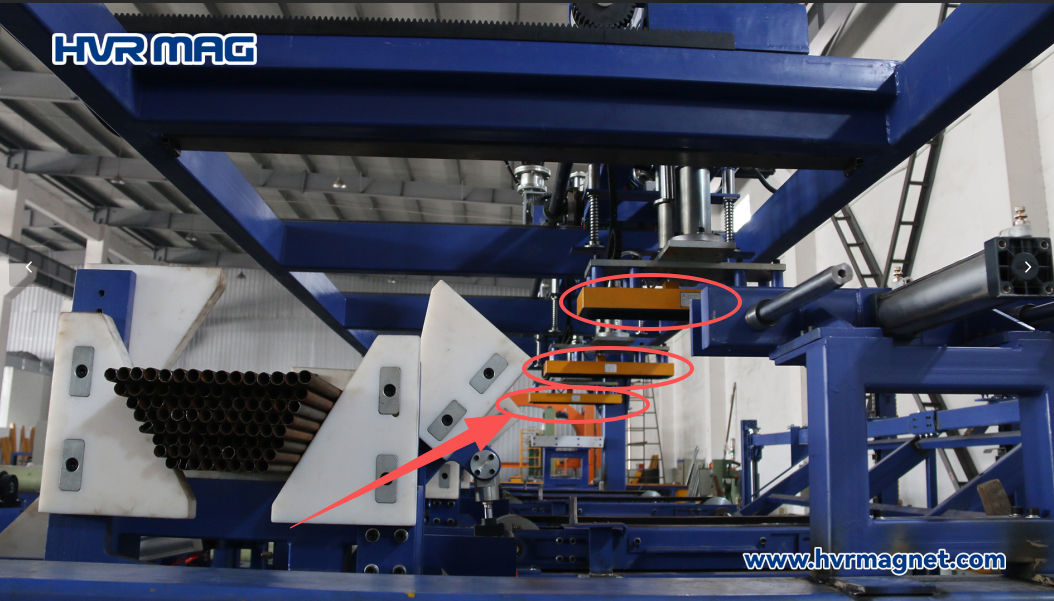

At HVR MAG, we develop a magnetic solutions for industrial automation recently. In this project, we delivered a magnetic workholding system designed to work with a customer’s automated gantry for steel pipe palletising. The application required stable lifting, high efficiency, and reliable performance during continuous operation.Visit for more

The handled workpieces are steel pipes arranged in rows for palletising. Each row has a maximum width of 570 mm. Pipe wall thickness ranges from 1.2 to 4.0 mm, and the maximum lifting weight per cycle reaches 400 kg. Each pipe measures 6 meters in length, with diameters between 90 and 114 mm. These dimensions require balanced force distribution and precise control during handling.

HVR Solution

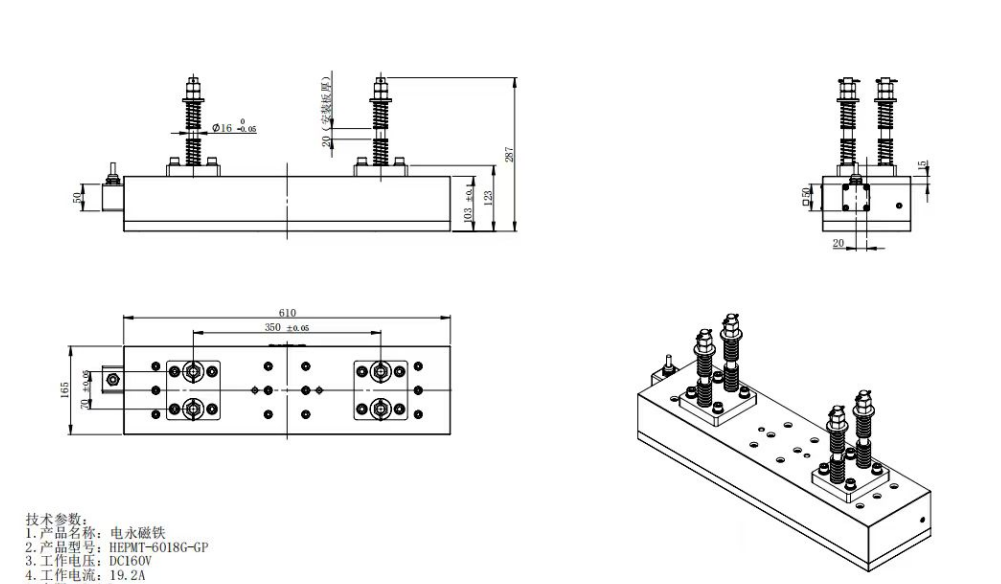

To meet these requirements, HVR MAG designed a solution using two HEPMT-6018G-GP electro-permanent magnets. Each magnet provides a rated holding force of 200 kg. Working together, the two magnets create stable and even lifting force across the steel pipes. This configuration allows the gantry system to lift, move, and stack the pipes smoothly.

The magnetic units integrate directly with the automated gantry structure. Simple control logic allows quick magnet activation and release during each handling cycle. The system performs repeated lifting operations with consistent holding force and accurate positioning. No tooling changes are needed when pipe diameter or wall thickness varies, which improves production flexibility.

During palletising, the gantry maintains steady motion from pickup to placement. The magnetic gripping method eliminates mechanical clamping and reduces the risk of surface damage or deformation. This helps maintain clean stacking and uniform pallet formation during long production runs.

The system supports smooth movement and consistent stacking, adapts to different pipe sizes, and improves efficiency in continuous production environments.Magnetic workholding system technology also supports energy-efficient operation. The magnets consume power only during magnetization and demagnetization. Once activated, they hold the load securely without continuous power input. This improves safety and reliability in automated handling environments.