In industrial magnetic gripper handling applications, certain materials present distinct challenges that standard equipment cannot adequately address. Among these are thin, flexible woven mesh materials approximately 0.5mm thick, which require careful consideration in both engineering approach and practical implementation.

Understanding the Material Handling Complexities

Woven mesh materials possess characteristics that complicate conventional handling methods. Their flexible nature, combined with minimal thickness, creates difficulties in maintaining flatness during transfer. Traditional vacuum systems often struggle with the porous structure, while mechanical clamps may distort or damage the delicate surface. The solution required careful analysis of material properties and handling parameters to develop an appropriate technical approach.

Technical Development Process

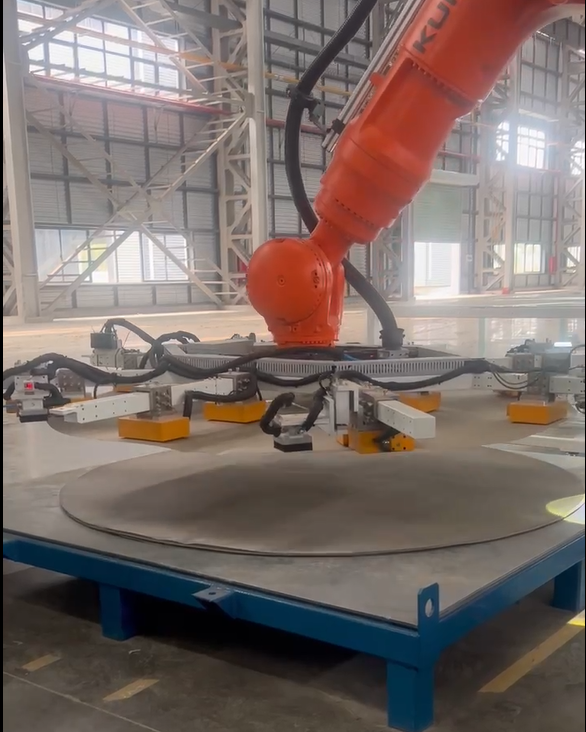

The magnetic gripper designed for this application underwent several iterations to achieve optimal performance. Through testing and refinement, we established a configuration using multiple small magnetic units arranged in a specific pattern. This arrangement generates a distributed holding force that supports the mesh evenly without creating stress concentrations. The electro-permanent technology allows controlled activation and deactivation while maintaining holding force without continuous power supply.

Implementation Considerations

Successful implementation requires attention to several operational factors. The magnetic force must be precisely calibrated – sufficient to securely hold the material during movement yet gentle enough to prevent surface deformation. The release mechanism ensures clean separation without residual adhesion. Integration with existing handling systems maintains workflow continuity while adding the specialized capability for delicate mesh materials.

Broader Implications for Specialized Handling

This development demonstrates how magnetic technology can be adapted to meet specific industrial needs beyond conventional steel plate handling. The principles applied in this solution – distributed force application, precise magnetic control, and customized configuration – may inform approaches to other specialized material handling challenges. Such tailored solutions represent the ongoing evolution of magnetic handling technology in industrial applications.

This technical overview presents the considerations and approach behind developing specialized magnetic handling solutions, highlighting how standard technology can be adapted to address unique material handling requirements in modern manufacturing environments.