In the ever-evolving world of manufacturing, efficiency and precision are paramount. One technology that has gained traction for its ability to significantly enhance operational speed and accuracy is the magnetic quick mold change system. But can this technology be applied to metal stamping machines, and if so, will it have any unintended effects on the metal workpieces being processed? Let’s explore these questions in detail.

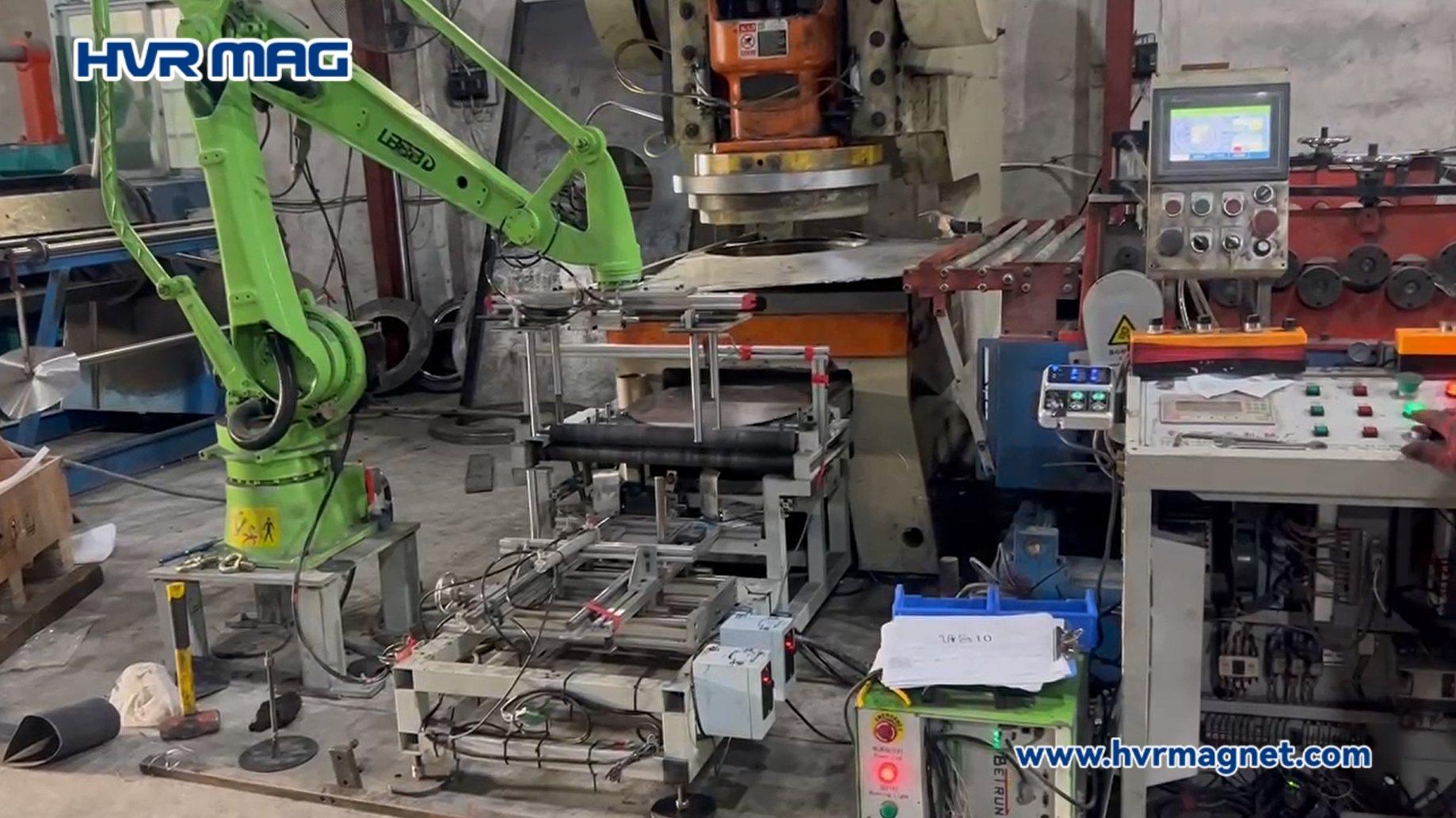

Application on Metal Stamping Machines

Metal stamping machines can shape and cut metal sheets through various processes such as punching and blanking. They can indeed benefit from the magnetic quick mold change system. These machines often require frequent mold changes due to the variety of produced parts. The magnetic quick mold change system can significantly streamline this process.

- Enhanced Efficiency: By allowing for faster and more straightforward mold changes, this system reduces the time spent on setup and maintenance, thus increasing machine uptime and productivity.

- Precision and Stability: The magnetic system ensures molds being precisely aligned and securely fixed during operation. This can lead to improved part accuracy and consistency.

- Reduced Labor Costs: Automation of mold changes reduces the need for manual intervention, thereby lowering labor costs and minimizing the risk of human error.

Concerns About Metal Workpiece Adsorption

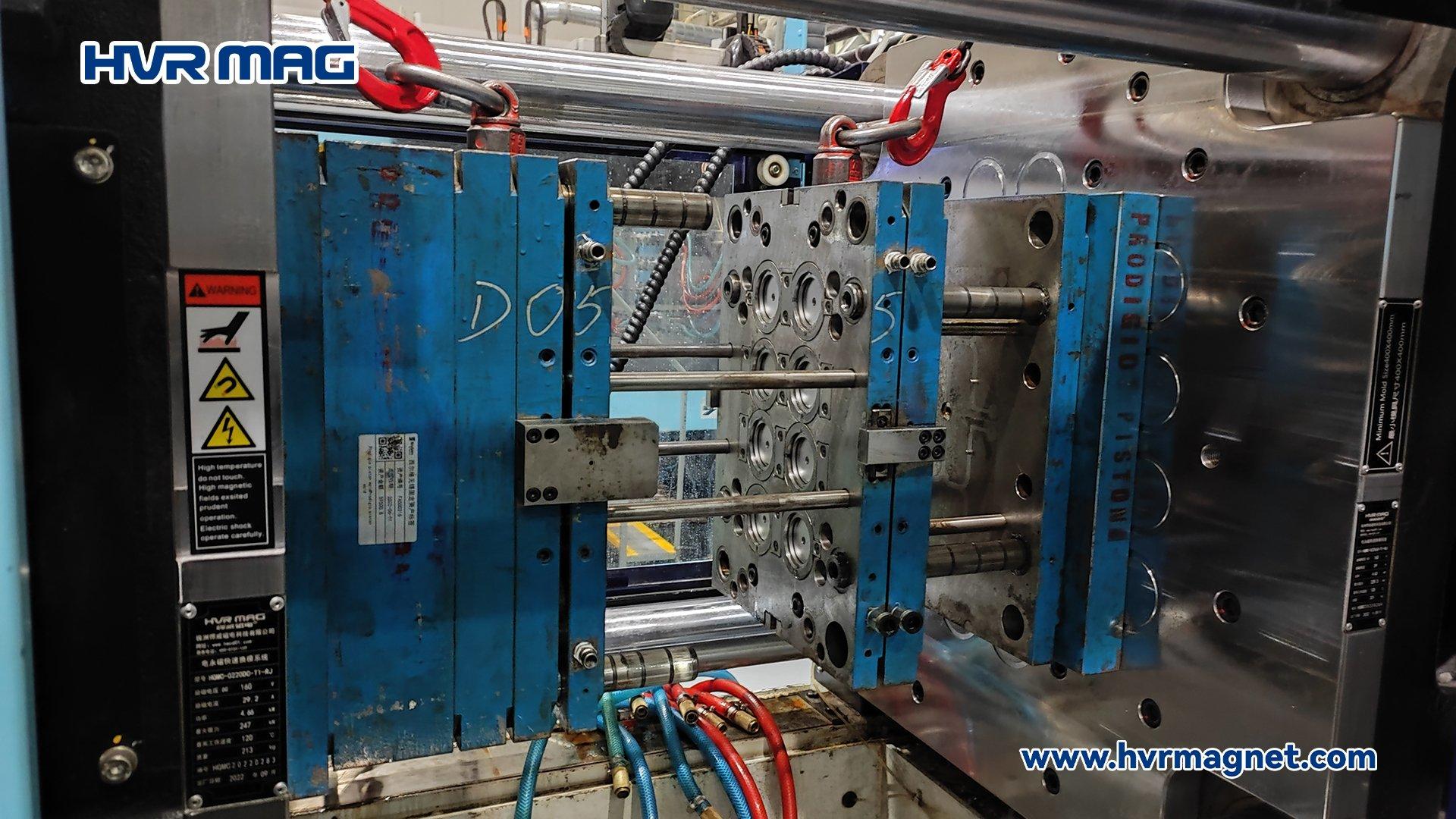

A common concern when using magnetic systems is whether they might inadvertently affect the metal workpieces. In the case of magnetic quick mold change systems, the design is specifically to address this issue:

- Smart Magnet Control: The system uses carefully adjusted magnets that only work on the mold, not the metal parts you’re working on. These magnets focus their power exactly where needed, keeping the stamping area completely magnet-free.

- No Effect on Your Metal Parts: Our design keeps all magnetic force strictly between the mold and its holder. This means your workpieces stay completely normal, no unwanted magnetic pull or other effects.

Conclusion

Magnetic quick mold change systems work in metal stamping machines, offering substantial benefits in terms of efficiency, precision, and cost reduction. The technology is to avoid any interference with the metal workpieces, thanks to carefully controlled magnetic forces and advanced materials. As a result, manufacturers can enjoy the advantages of rapid mold changes without the risk of adsorbing or affecting their metal workpieces.