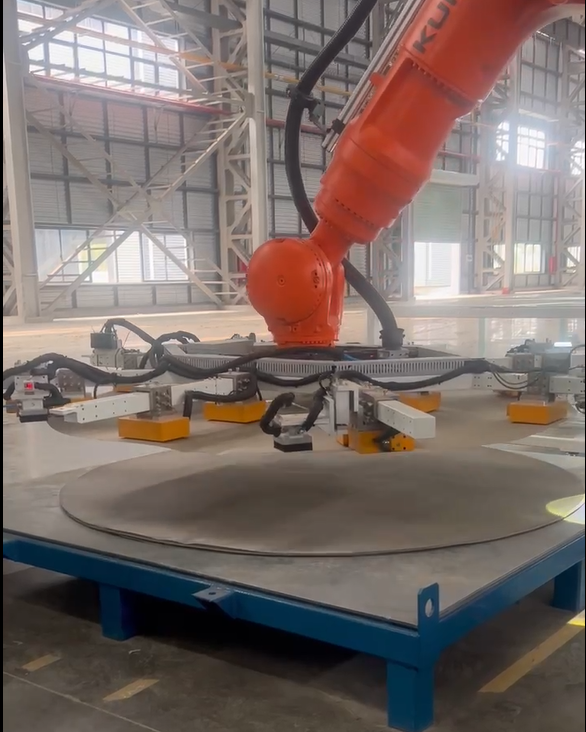

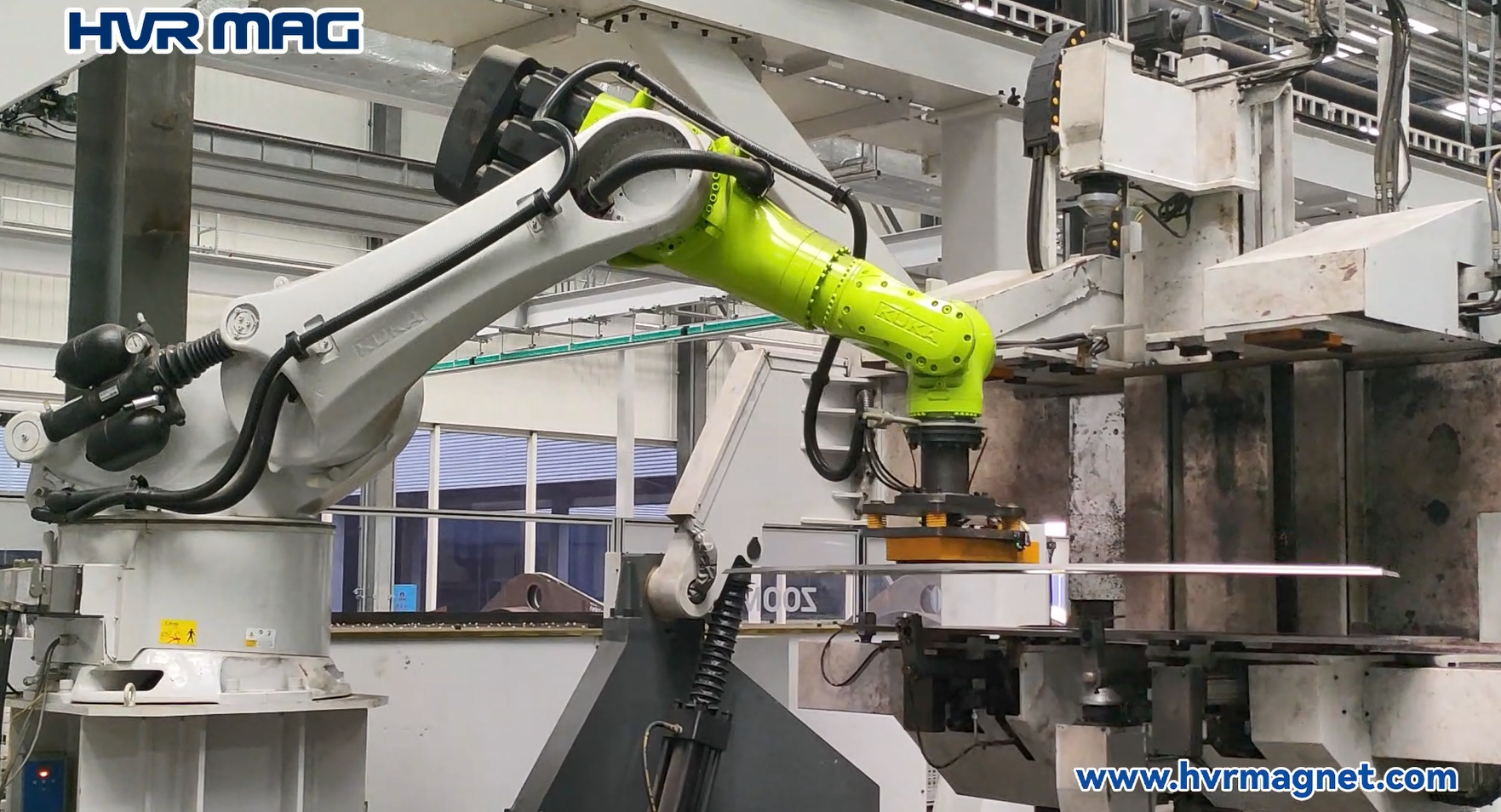

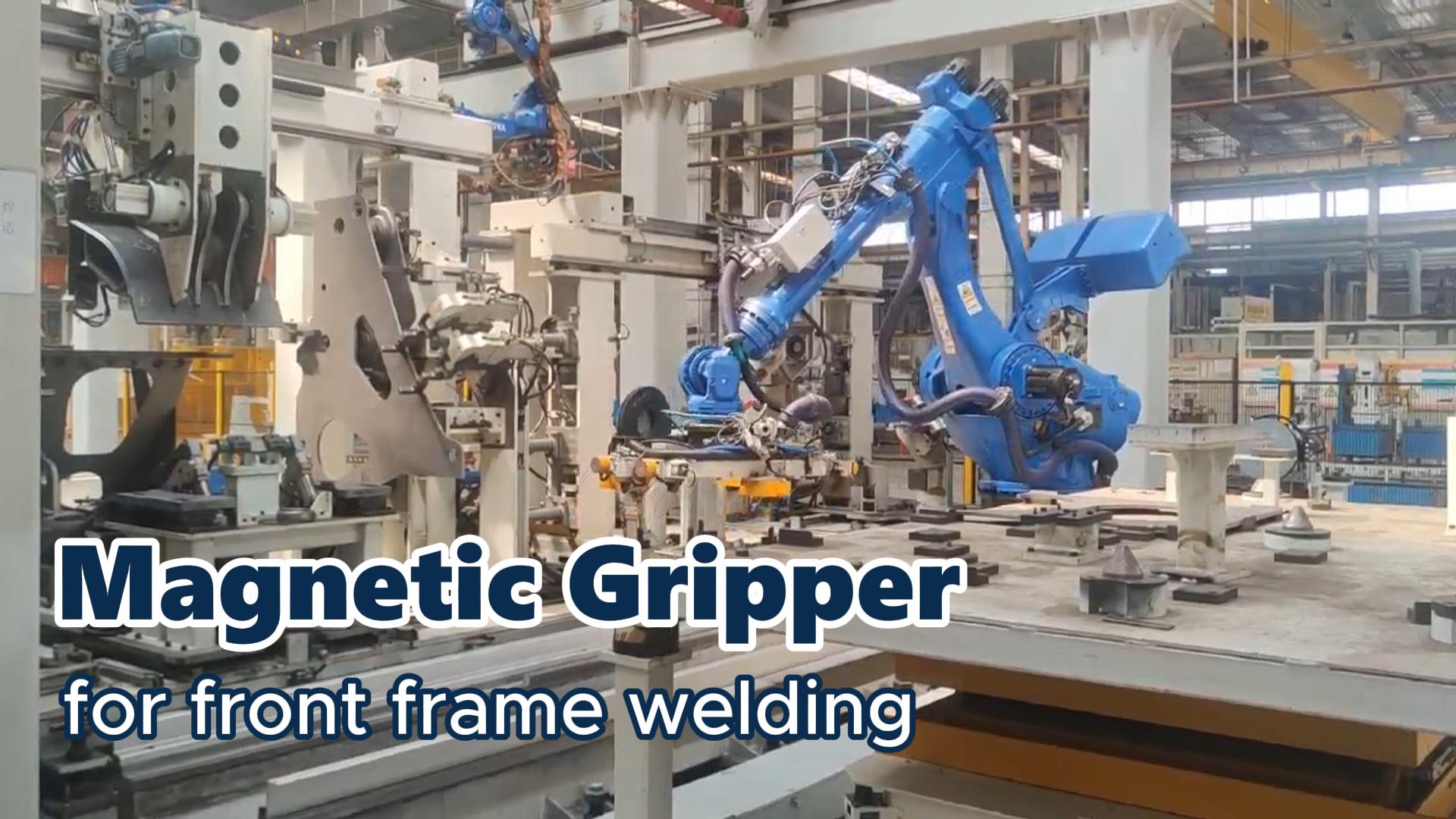

Addressing Unique Handling Challenges with Specialized Magnetic Solutions

In industrial magnetic gripper handling applications, certain materials present distinct challenges that standard equipment cannot adequately address. Among these are thin, flexible woven mesh materials approximately 0.5mm thick, which require careful consideration in both engineering approach and practical implementation. Understanding the Material Handling Complexities Woven mesh materials possess characteristics that […]

Addressing Unique Handling Challenges with Specialized Magnetic Solutions Keep Reading »