When it comes to injection molding, the efficiency of mold changing processes plays a critical role in determining overall productivity. Two commonly used quick mold change systems, hydraulic and magnetic, offer distinct differences in the time required for mold clamping. Taking a 600-ton injection molding machine as an example, let us delve into the nuances of these systems and their impact on mold clamping time.

Hydraulic Quick Mold Change Systems

A hydraulic quick mold change system typically involves manually operating 4-6 hydraulic clamps to secure the mold in place. This process introduces variations in clamping time, usually ranging from 60 to 80 seconds. The time taken to lock the mold is influenced by factors such as the thickness of the mold and the length of hydraulic pipelines. As a result, the clamping time can fluctuate based on these variables, potentially leading to inconsistent mold change times.

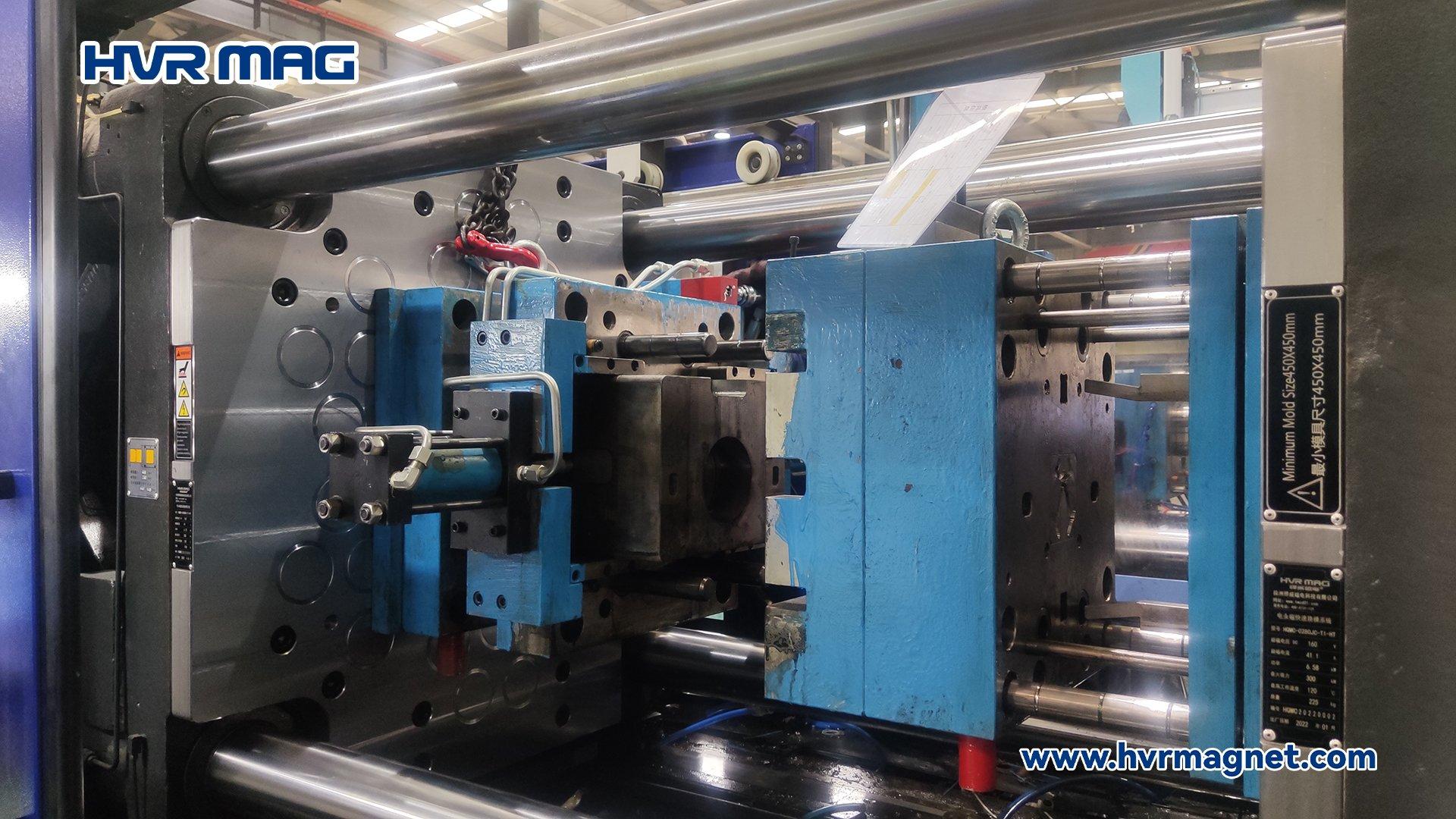

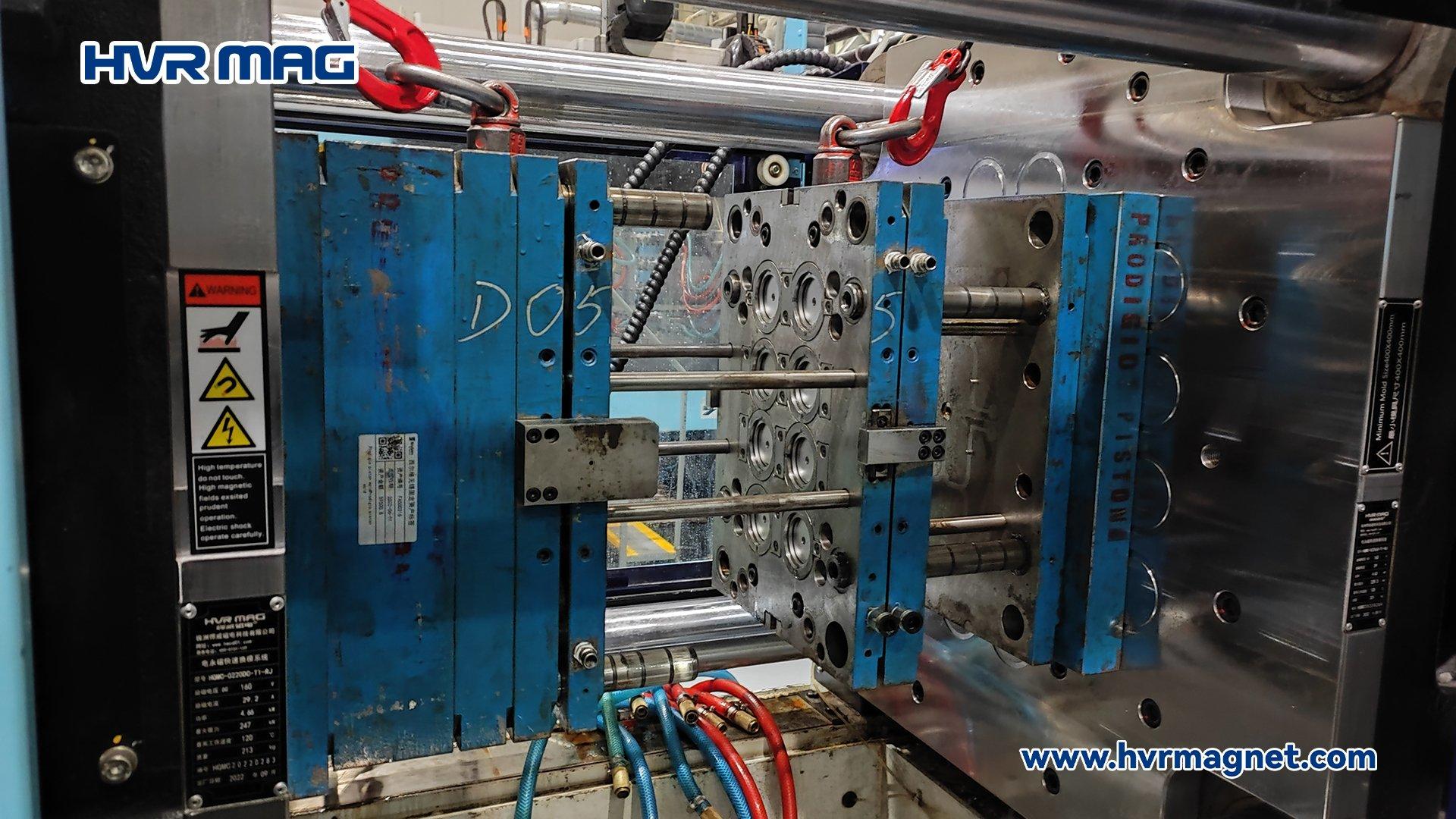

Magnetic Quick Mold Change Systems

In contrast, a magnetic quick mold change system functions by using an operator-controlled panel to magnetize or demagnetize the system. This streamlined process enables the mold to be clamped in a mere 2-3 seconds, significantly reducing the time required for mold changing operations. By leveraging magnetic forces, the system offers swift and efficient mold clamping, enhancing overall production efficiency.

Conclusion

The significant reduction in mold clamping time can have a substantial impact on production efficiency. Faster mold changes mean less downtime between production runs, allowing for processing more molds in a shorter amount of time. This increase in productivity can translate to cost savings and improved overall output for manufacturers utilizing magnetic systems.

In conclusion, when comparing hydraulic and magnetic quick mold change systems in terms of mold clamping time, it is evident that the magnetic system offers a significant advantage in speed and efficiency. With a quick and reliable clamping process, magnetic systems enable manufacturers to streamline their production operations and enhance their competitive edge in the market. For more information, please contact HVR MAG at export@hvrmagnet.com