In today’s industrial landscape, non-standard customization is becoming increasingly common, and with it comes the need for versatile and reliable clamping solutions. Whether you’re working with non-standard equipment or high-precision machining, electro permanent magnetic chucks offer a range of benefits that make them an indispensable part of modern manufacturing.

What Are Electro Permanent Magnetic Chucks?

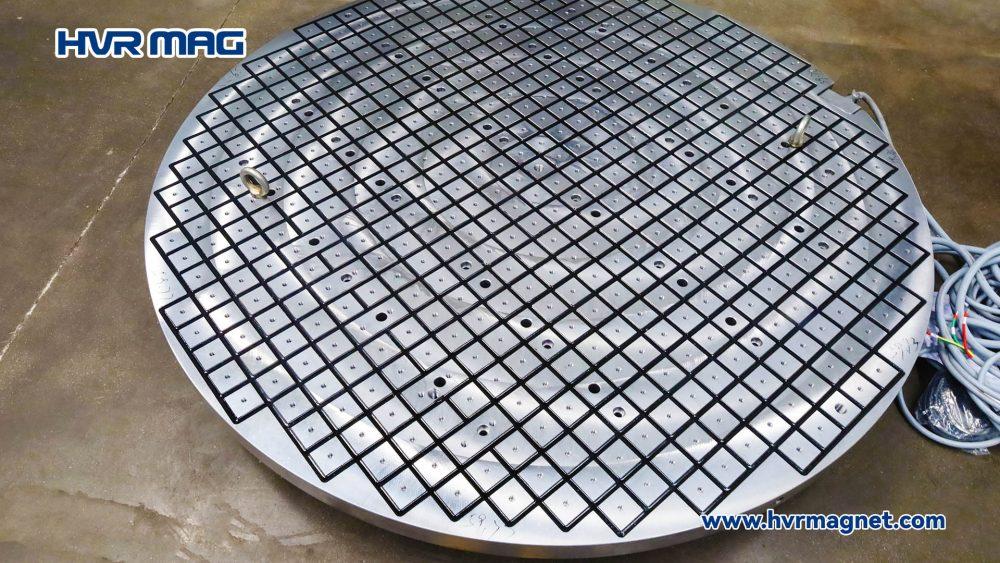

These clamping chuck are advanced clamping devices that use a combination of neodymium iron boron (NdFeB) and aluminum nickel cobalt (AlNiCo) to generate a strong and stable magnetic force. These materials create a magnetic circuit that can produce an impressive 18 kg of holding force per square centimeter. What sets electro permanent magnets apart is their ability to magnetize and demagnetize with just a brief pulse of electric current, making them highly efficient and easy to control.

Key Advantages

- Strong and Reliable Holding Force

They provide a powerful and consistent magnetic force, ensuring that workpieces remain securely in place during machining or handling. This is particularly important in high-precision applications where even the slightest movement can lead to errors.

- Energy Efficiency

Unlike traditional clamping systems that require continuous power, these chucks only need electricity during the brief moments of magnetization and demagnetization. Once activated, they rely on the permanent magnet’s properties to maintain their grip, resulting in significant energy savings. This makes them an eco-friendly choice for modern manufacturing.

- Easy to Use and Maintain

They are designed for simplicity and durability. They don’t require complex hydraulic, mechanical, or pneumatic systems, which reduces maintenance costs and downtime. Additionally, their modular design allows for easy customization to fit various machine tools and workpiece sizes.

- Safety and Automation Compatibility

One of the standout features of electro permanent magnetic chucks is their fail-safe design. Even in the event of a power outage, the chucks retain their magnetic force, ensuring that workpieces remain securely clamped. This makes them ideal for automated systems, where reliability and safety are paramount.

Applications of Electro Permanent Magnetic Chucks

Electro permanent magnetic chucks are incredibly versatile and can be used in a wide range of industries, including:

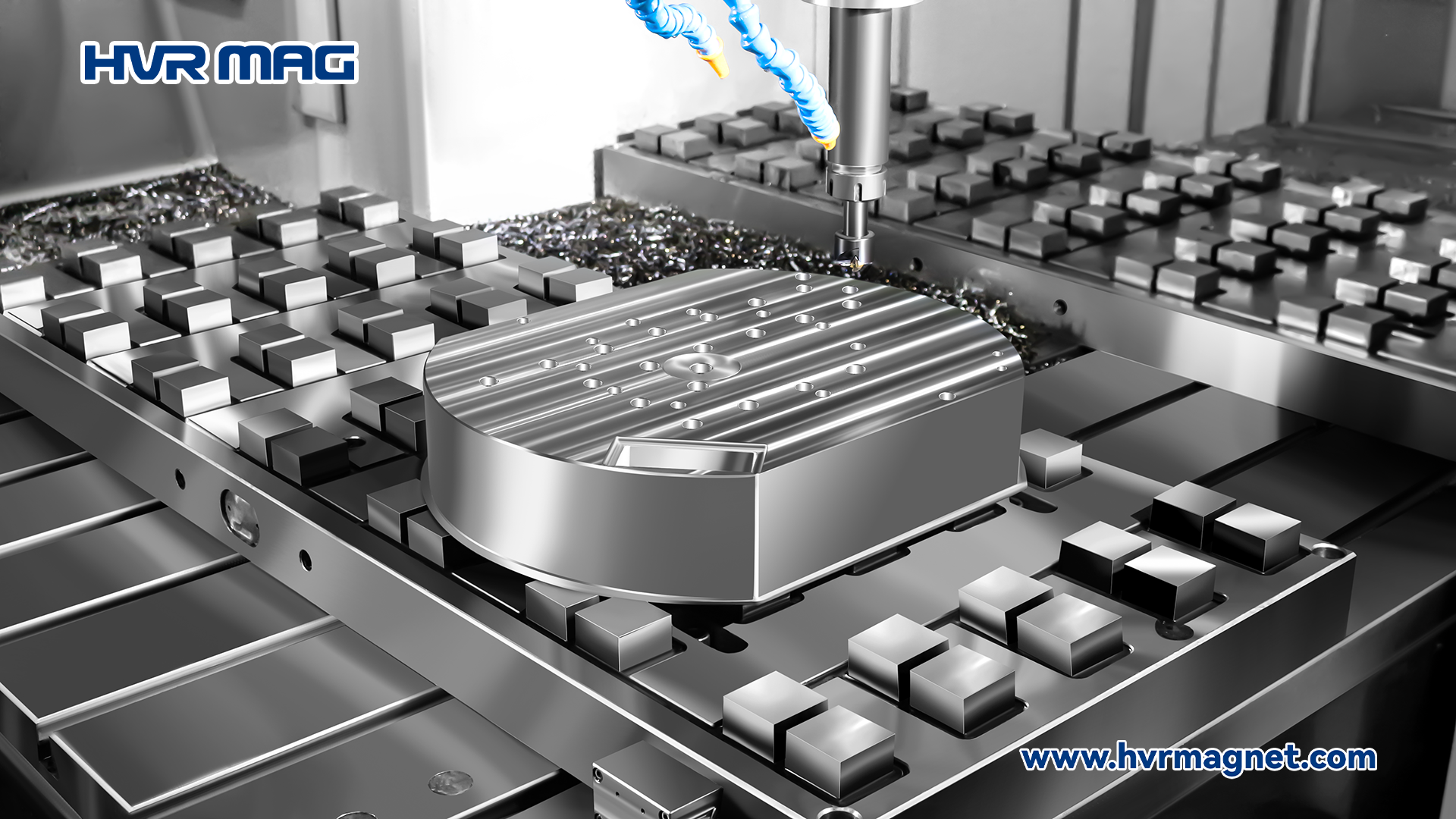

Machining and Fabrication: They are perfect for securing workpieces during milling, grinding, and other machining processes. Their high holding force ensures precision and stability, even for complex parts.

Automotive and Aerospace: In industries where precision is critical, they provide the reliability needed for high-quality manufacturing.

Custom Machinery: These chucks can be tailored to fit non-standard equipment, making them a flexible solution for specialized applications.

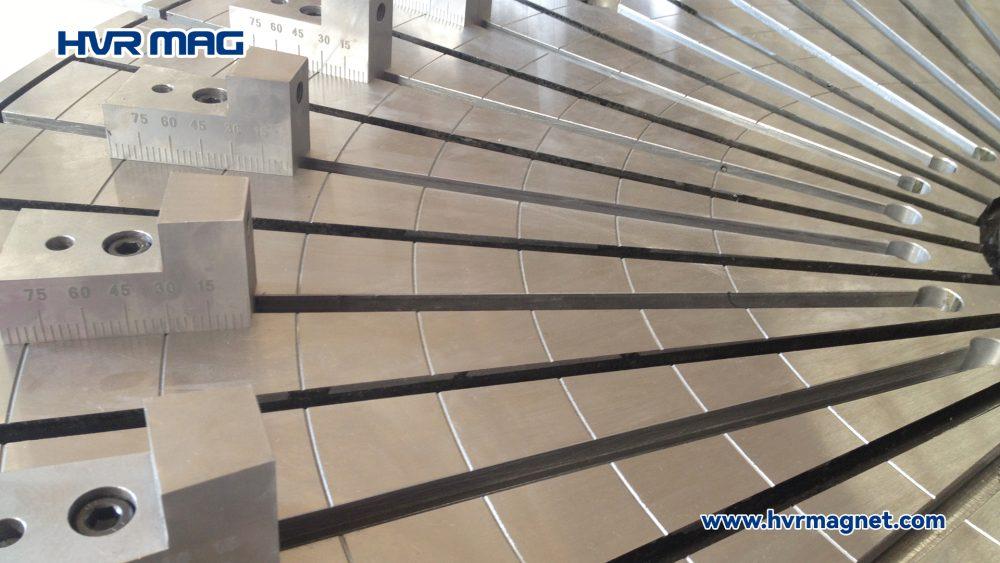

Double-Sided Electro Permanent Magnetic Chucks

For applications requiring even greater flexibility, double-sided electro permanent magnetic chucks are an excellent option. These chucks allow for quick and easy repositioning of workpieces, making them ideal for multi-step machining processes. Here’s how they work:

- Setup: Determine the number of chucks needed based on the workpiece size and arrange them to avoid interference with machine tool components.

- Magnetization: Activate the chucks using the control panel to securely hold the workpiece in place.

- Machining: Perform the necessary operations with confidence, knowing the workpiece is firmly clamped.

- Demagnetization: Once machining is complete, demagnetize the chucks to release the workpiece quickly and safely.

Why Choose HVR MAG?

At HVR MAG, we specialize in designing and manufacturing high-quality electro permanent magnetic chucks that meet the demands of modern industry. Our chucks are modular, highly rigid, and precision-engineered to ensure optimal performance in even the most challenging applications. Whether you’re working with standard machine tools or custom equipment, our electro permanent magnetic chucks offer the reliability and versatility you need to stay ahead.