In the powder metallurgy industry, the mold release process is a critical step. It can significantly impact production efficiency and worker safety. Traditionally, this process has relied on manual methods, such as tightening screws to secure molds, which are not only time-consuming but also pose serious challenges in high-temperature environments. Enter electro permanent magnetic chucks, a cutting-edge solution that is transforming the way molds are handled during the release process.

The Challenges of Traditional Mold Release

In powder metallurgy, molds are often subjected to extremely high temperatures, sometimes exceeding 200-300°C after cooling. In such conditions, workers are required to manually tighten screws to secure the molds. This process can take 10 minutes or more in sweltering heat. This not only affects worker comfort and safety but also leads to inefficiencies. Over time, the high temperatures can cause screws to deform, resulting in misalignment issues that further prolong the process and require additional manual intervention.

The Electro Permanent Magnetic Chuck Solution

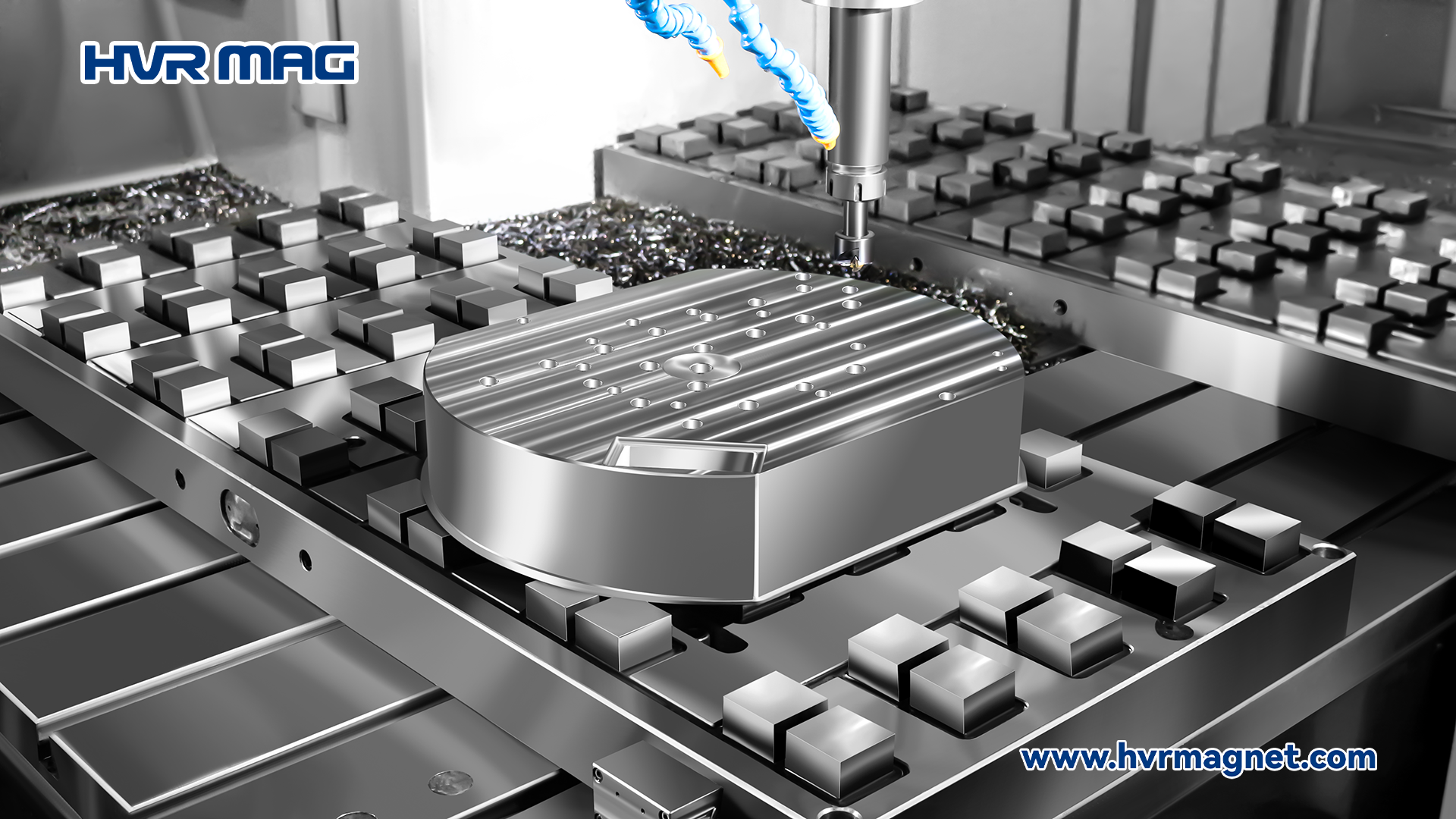

Electro permanent magnetic chucks offer a modern, efficient, and safe alternative to traditional screw-based methods. Here’s how they work and why they’re making a difference:

- Eliminating Manual Screw Tightening

These chucks use magnetic force to securely hold molds in place, eliminating the need for manual screw tightening. This not only speeds up the mold release process but also reduces the time workers spend in high-temperature environments, significantly improving their safety and comfort.

- High-Temperature Resistance

Designed to withstand extreme heat, these magnetic chucks are made from heat-resistant materials and often include water-cooling systems to prevent demagnetization. This ensures that the chucks maintain their magnetic force even in temperatures as high as 300°C, providing reliable performance in demanding conditions.

- Precise and Uniform Holding Force

Unlike screws, which can cause uneven pressure and misalignment, magnetic chucks provide a uniform magnetic force across the entire mold surface. This results in more accurate positioning and reduces the risk of errors during the mold release process.

Application: A Case Study

One of our clients, a large state-owned enterprise specializing in the production of brake discs for subways and automobiles, faced significant challenges with their traditional mold release process. The molds, weighing up to 150 kg, required manual screw tightening, which was inefficient and unsafe due to the high temperatures involved.

After implementing electro permanent magnetic chucks, the client saw immediate improvements:

Increased Efficiency: The elimination of manual screw tightening reduced the mold release time significantly.

Enhanced Safety: Workers spent less time in high-temperature environments, reducing the risk of heat-related issues.

Improved Precision: The uniform magnetic force provided by the electro permanent magnetic chucks ensured accurate mold positioning, minimizing errors.

Why Electro Oermanent Magnetic Chucks Are the Future of Mold Release

Electro permanent magnetic chucks are not just a tool—they’re a comprehensive solution to the challenges faced in powder metallurgy and other high-temperature industries. By combining efficiency, safety, and precision, they are setting a new standard for mold release processes. Whether you’re dealing with large molds, high temperatures, or complex production lines, electro permanent magnetic chucks offer a reliable and innovative way to streamline operations.

Conclusion

The introduction of electro permanent magnetic chuck is revolutionizing the mold release process in powder metallurgy. By eliminating manual screw tightening, resisting high temperatures, and providing precise holding force, electro permanent magnetic chucks are enhancing both productivity and worker safety. For industries looking to modernize their operations and improve efficiency, electro permanent magnetic chucks are the ultimate solution.