Electro Permanent Steel Sheet Lifting Magnets

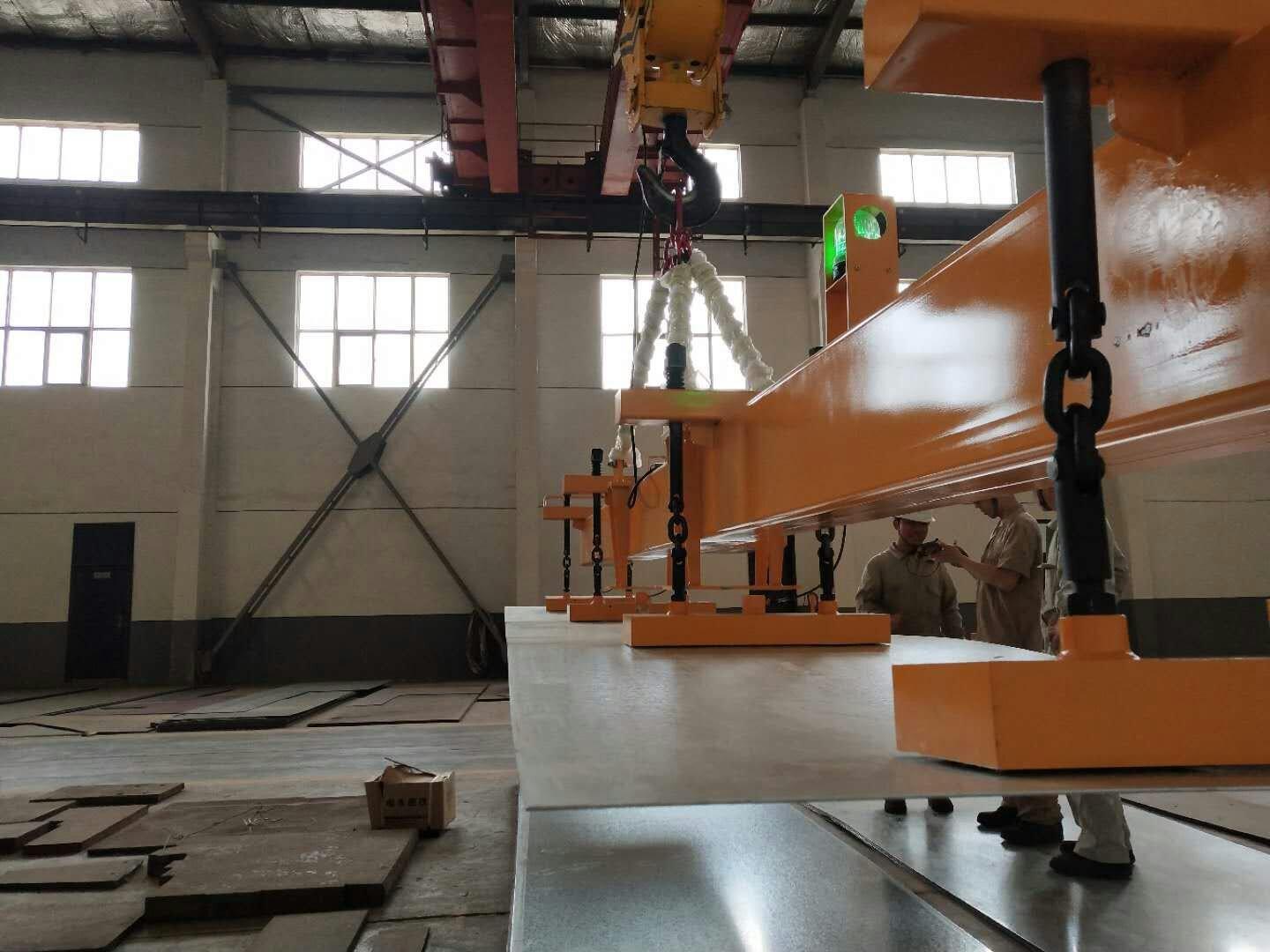

Electro Permanent Steel Sheet Lifting Magnets, engineered for steel plates as thin as 1.5 mm. It utilizes electro permanent magnet modules, elastically suspended for adaptability to plate contours, ensuring secure handling of long, flexible steel sheets.

- Thickness Lifting: Starting from a minimum thickness of 1.5mm

- Single Sheet Lifting: Handling of individual steel sheets with precision.

- Multi-Level Pickup: 4 Levels integrated cycle for thin plates.

- Landing Detection: prevent unintentional demagnetization while the steel sheet is airborne.

- Remote Control: Digital push buttons and radio remote control

- High Safety: 3:1 safety factor.

- HM3 Series Electro Permanent Steel Sheet Lifting Magnets

- HM2 Series Electro Permanent Magnetic Telescopic Lifting Beam

- HBEPP Serie Battery Powered Lifting Magnets For Plates

| Art No. | Series Code | Length(mm/in) | Width(mm/in) | Thickness(mm/in) | Dead Weight(kg/Lbs) | Capacity(kg/Lbs) | ||

| Min. | Max. | Min. | Max. | Min. | ||||

| HM3-03-010 | HM3-010H0203-1 | 500/20 | 3000/118 | 1000/39 | 2500/98 | 3/0.1 | 550/1210 | 1000/2200 |

| HM3-06-020 | HM3-020H0206-1 | 1200/47 | 6000/236 | 1000/39 | 2500/98 | 3/0.1 | 700/1540 | 2000/4400 |

| HM3-09-030 | HM3-030H0209-1 | 1715/67.5 | 9000/354 | 1000/39 | 2500/98 | 3/0.1 | 1000/2200 | 3000/6600 |

| HM3-12-040 | HM3-040H0212-1 | 2900/114 | 12000/472 | 1000/39 | 2500/98 | 3/0.1 | 1300/2860 | 4000/8800 |

| Art No. | Series Code | Length(mm/in) | Width(mm/in) | Thickness(mm/in) | Dead Weight(kg/Lbs) | Capacity(kg/Lbs) | ||

| Min. | Max. | Min. | Max. | Min. | ||||

| HM2-12-050 | HM2-050A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2350/5170 | 5000/11000 |

| HM2-12-080 | HM2-080A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2500/5500 | 8000/17600 |

| HM2-12-090 | HM2-090A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2650/5830 | 9000/19800 |

| HM2-12-120 | HM2-120A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2800/6160 | 12000/26400 |

| HM2-12-150 | HM2-150A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2950/6490 | 15000/33000 |

| HM2-12-200 | HM2-200A0206-1 | 3800/149.6 | 12000/472 | 500/20 | 3500/137.8 | 8/0.3 | 3350/7370 | 20000/44000 |

| HM2-12-240 | HM2-240A0206-1 | 3800/149.6 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 3550/7810 | 24000/52800 |

| HM2-16-090 | HM2-090A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3300/7260 | 9000/19800 |

| HM2-16-120 | HM2-120A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3400/7480 | 12000/26400 |

| HM2-16-160 | HM2-160A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3600/7920 | 16000/35200 |

| HM2-16-200 | HM2-200A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3800/8360 | 20000/44000 |

| HM2-16-240 | HM2-240A0206-1 | 3100/122 | 16000/630 | 250/9.8 | 500/20 | 5/0.2 | 4000/8800 | 24000/52800 |

| Art No. | Series Code | Length(mm/in) | Width(mm/in) | Thickness(mm/in) | Dead Weight(kg/Lbs) | Capacity(kg/Lbs) | ||

| Min. | Max. | Min. | Max. | Min. | ||||

| HBEPP-03-008 | HBEPP-008L0203-2 | 500/20 | 3000/118 | 900/35.4 | 2000/79 | 2/0.1 | 465/1023 | 600/13200 |

| HBEPP-03-010 | HBEPP-010A0102-2 | 500/20 | 3000/118 | 500/20 | 1500/59 | 5/0.2 | 500/1100 | 1000/22000 |

| HBEPP-06-030L | HBEPP-030A0204-2 | 1700/66.9 | 6000/236 | 500/20 | 2000/79 | 2/0.1 | 1140/2508 | 3000/66000 |

| HBEPP-15-014 | HBEPP-025A0108-2 | 2100/82.6 | 15000/590 | 310/12.2 | 800/31 | 5/0.2 | 1090/2398 | 1400/30800 |

| HBEPP-06-030 | HBEPP-030B0203-2 | 500/20 | 6000/236 | 500/20 | 3500/137.8 | 5/0.2 | 950/2090 | 3000/66000 |

| HBEPP-06-060 | HBEPP-060J0203-2 | 500/20 | 6000/236 | 500/20 | 3500/137.8 | 5/0.2 | 1250/2750 | 6000/132000 |

| HBEPP-06-090 | HBEPP-090J0203-2 | 300/11.8 | 6000/236 | 600/23.6 | 3500/137.8 | 6/0.2 | 950/2090 | 9000/198000 |

| HBEPP-09-080 | HBEPP-080J0204-2 | 2500/98.4 | 9000/354 | 500/20 | 3500/137.8 | 5/0.2 | 1640/3608 | 8000/176000 |

| HBEPP-09-120 | HBEPP-120J0204-2 | 2500/98.4 | 9000/354 | 500/20 | 3500/137.8 | 5/0.2 | 1750/3850 | 12000/264000 |

| HBEPP-12-100 | HBEPP-100J0205-2 | 500/20 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2010/4422 | 10000/220000 |

| HBEPP-12-180 | HBEPP-180J0208-2 | 1700/66.9 | 12000/472 | 1200/47.2 | 3500/137.8 | 5/0.2 | 3260/7172 | 18000/396000 |

| HBEPP-06-020/T | HBEPP-020B0104-2 | 500/20 | 6000/236 | 250/9.8 | 500/20 | 6/0.2 | 780/1716 | 2000/44000 |

| HBEPP-06-060/T | HBEPP-060B0104-2 | 500/20 | 6000/236 | 500/20 | 3500/137.8 | 6/0.2 | 1030/2260 | 6000/132000 |

| HBEPP-16-200 | HBEPP-200J0208-2 | 2100/82 | 16000/630 | 1300/51 | 3500/137.8 | 6/0.2 | 4650/10230 | 20000/44000 |

| HBEPP-16-250 | HBEPP-250J0208-2 | 2100/82 | 16000/630 | 1300/51 | 3500/137.8 | 6/0.2 | 4860/10692 | 25000/55000 |

Electro Permanent Steel Sheet Lifting Magnets

The HM3 Series Electro Permanent Steel Sheet Lifting Magnets are designed to address the challenges of lifting long, thin, and flexible steel plates from 1.5 to 6mm in thickness, ensuring safe and precise handling without picking up additional sheets and adapting to sheet deflection to minimize deformation.

Particularly in applications such as steel fabrication, warehousing, and manufacturing, where precise and secure lifting is crucial to prevent deformation and ensure worker safety.

Electro Permanent Steel Sheet Lifting Magnets Advantage

-High Safety: Minimizing the risk of workplace injuries by reducing manual handling of thin and potentially sharp steel plates.

-EfficiencyHandling: Speeding up material handling processes, which is crucial for production timelines and operational flow.

-Precision Placement: Ensuring accurate positioning, which is essential for quality control in manufacturing and construction.

-Cost Savings: Reducing labor costs and the potential for material damage, leading to cost savings.

-Surface Protection: Preventing damage to the surface of thin steel plates, which can be critical for both aesthetic and functional reasons.

Electro Permanent Steel Sheet Lifting Magnets Mill Application

Electro Permanent Steel Sheet Lifting Magnets effectively manage and transport fragile and thin steel sheets, guaranteeing safe and accurate movement without causing any damage.

It improves the production workflow by decreasing manual labor, lowering the chances of accidents, and enhancing the storage and retrieval of thin steel plates. And increases productivity while maintaining the material’s integrity throughout various mill operations.

Electro Permanent Steel Sheet Lifting Magnets Steel Processing Application

Electro Permanent Steel Sheet Lifting Magnets in metal fabrication shops are essential for safely and efficiently handling delicate steel sheets.

They enable precise manipulation, minimizing manual injury risks and surface damage during cutting and forming, securely transported from storage to workstations.