Introduction:

In the field of automation and robotics, gripper mechanisms serve as adaptable tools capable of executing a wide range of tasks with accuracy and effectiveness. These essential components operate quietly across numerous industries, including assembly lines, packaging, and more. This blog explores the various types of gripper mechanisms, highlighting HVR MAG’s electro permanent magnetic grippers, and provides a thorough overview that is both informative and engaging.

A variety of gripper mechanisms types are available for use with robots and cranes. Some designs mimic human hands, featuring five fingers, although this is not universally applicable. There are also grippers with two or three fingers, claw-shaped grippers, mechanical types, those equipped with large suction cups, and even designs resembling air-filled bags. Given the extensive range of options, determining the most suitable robot gripper types for specific applications can be challenging.

Types of Gripper Mechanisms

1. Pneumatic Grippers:

– These grippers use air pressure to open and close, offering variable gripping forces and quick operation speeds. They are ideal for general-purpose applications but require a constant air supply.

2. Hydraulic Grippers:

2. Hydraulic Grippers:

– Known for their high gripping force, hydraulic grippers are suitable for heavy-duty tasks. They are more complex and require a hydraulic power source.

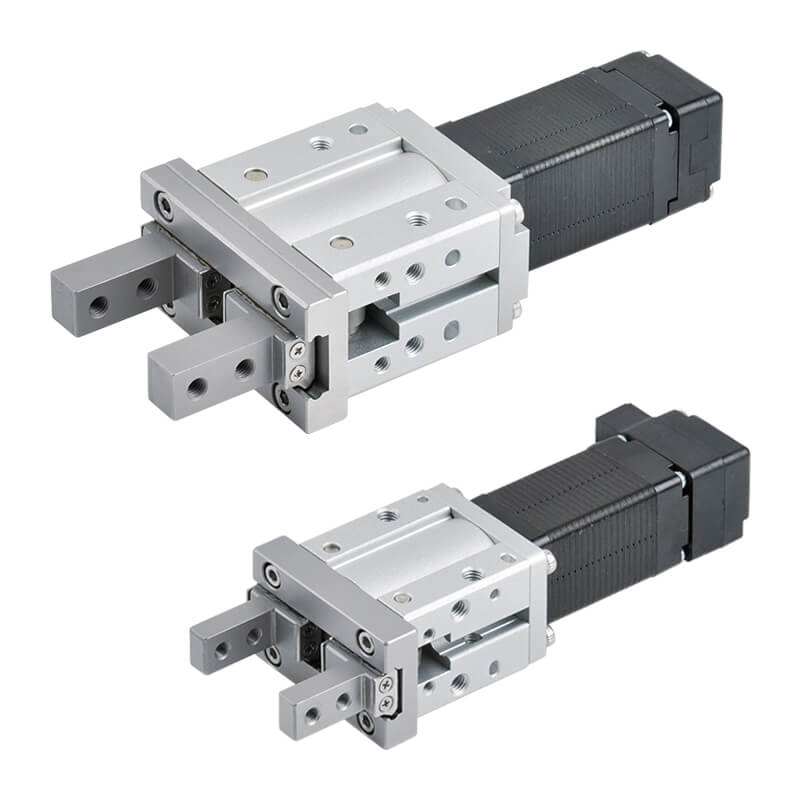

3. Electric Grippers:

– Electric grippers offer precise control and are easily integrated into automated systems. They are versatile and can be programmed for specific gripping sequences.

4. Magnetic Grippers:

4. Magnetic Grippers:

– Utilizing magnetic forces, these grippers are perfect for handling ferromagnetic materials without physical contact, reducing wear and tear.

5. Vacuum Grippers:

5. Vacuum Grippers:

– Ideal for non-magnetic, smooth surfaces, vacuum grippers create a seal to lift items, making them suitable for delicate or non-ferrous materials.

Magnetic Gripper-Most Advanced Technology

Magnetic grippers play a crucial role in material handling, especially within the steel industry, where their capacity to firmly grasp and transport ferrous materials is essential. Notably, HVRMAG electro-permanent magnetic gripper stands out because of their distinctive blend of electromagnetic and permanent magnetic characteristics. Here’s why:

- Efficient Power Utilization: Electro-permanent magnetic grippers necessitate only a short burst of electrical activation to establish their magnetic field, after which they sustain a robust grip without the need for ongoing power, rendering them an energy-efficient option.

- Safety and Dependability: Featuring a “fail-safe” mechanism, these grippers guarantee that steel remains firmly secured even during a power outage, thereby averting accidents and promoting a secure working environment.

- Flexibility and Customization: Designed to manage a range of steel materials, from plates to beams, electro-permanent magnetic grippers can be customized for various weights and dimensions, offering versatility across multiple applications.

- Decreased Labor and Enhanced Accuracy: These devices reduce the need for manual labor and minimize the potential for human error, providing precise control over the handling of heavy steel components, which is essential in precision manufacturing.

- Economic Viability and Durability: Although the initial cost may be elevated, the long-term benefits in energy savings, lower maintenance requirements, and improved productivity render electro-permanent magnetic grippers a financially sound investment. Their robust construction also ensures an extended service life.

- Environmental Responsibility: The energy-efficient characteristics of these grippers support environmentally sustainable practices, contributing to a reduction in the carbon footprint associated with material handling in the steel sector.

Conclusion:

Gripper mechanisms play a crucial yet often overlooked role in the realm of industrial automation. HVR MAG’s electro permanent magnetic grippers stand as a testament to the integration of precision, safety, and efficiency. As industries continue to advance, the need for dependable and adaptable gripping solutions increases, positioning HVR MAG as a leader in providing grippers that not only meet but surpass these expectations.

Explore the impact that HVR MAG’s electro permanent magnetic grippers can have on your operations. Reach out to us today to discover more about our cutting-edge solutions.