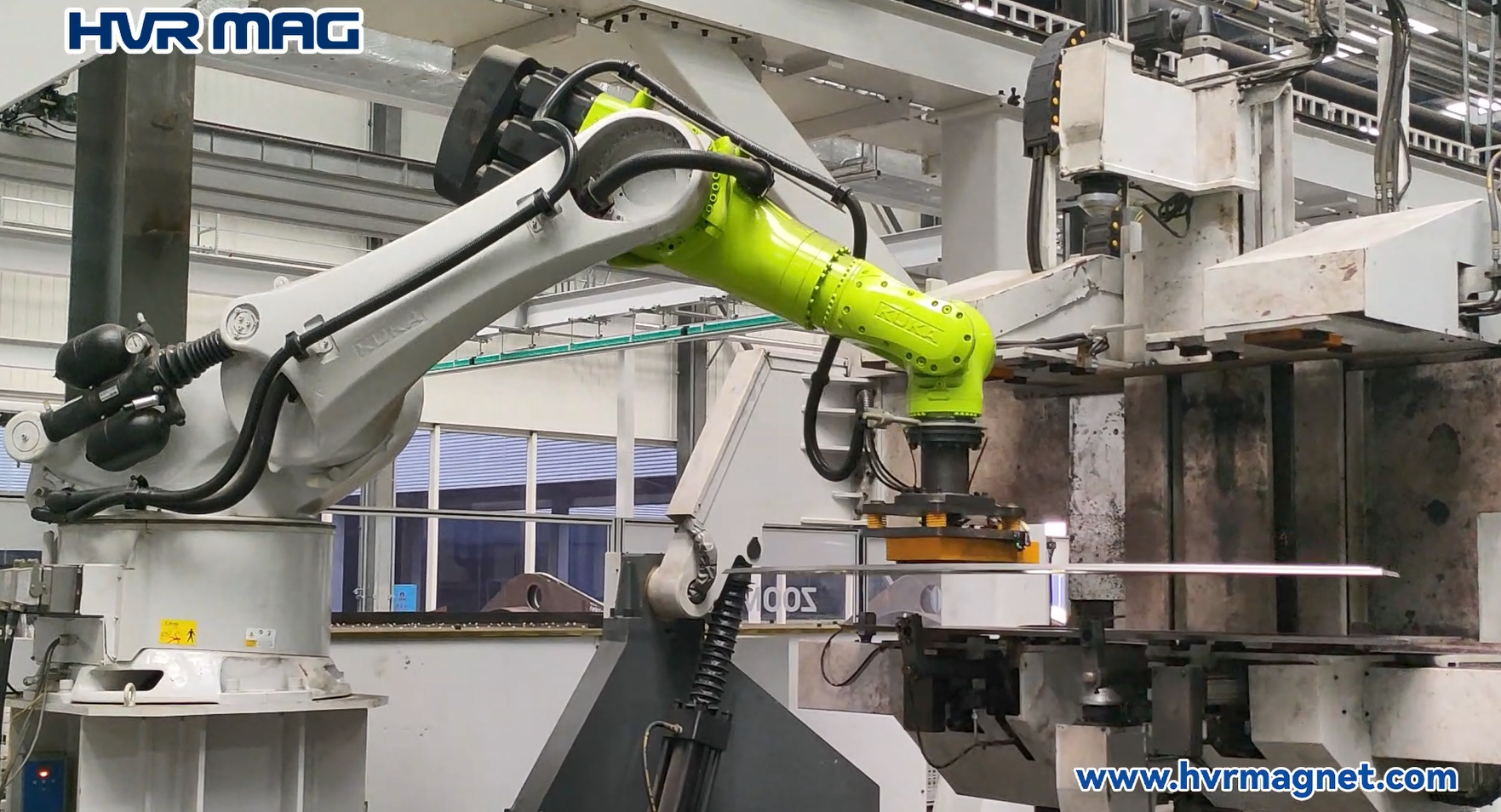

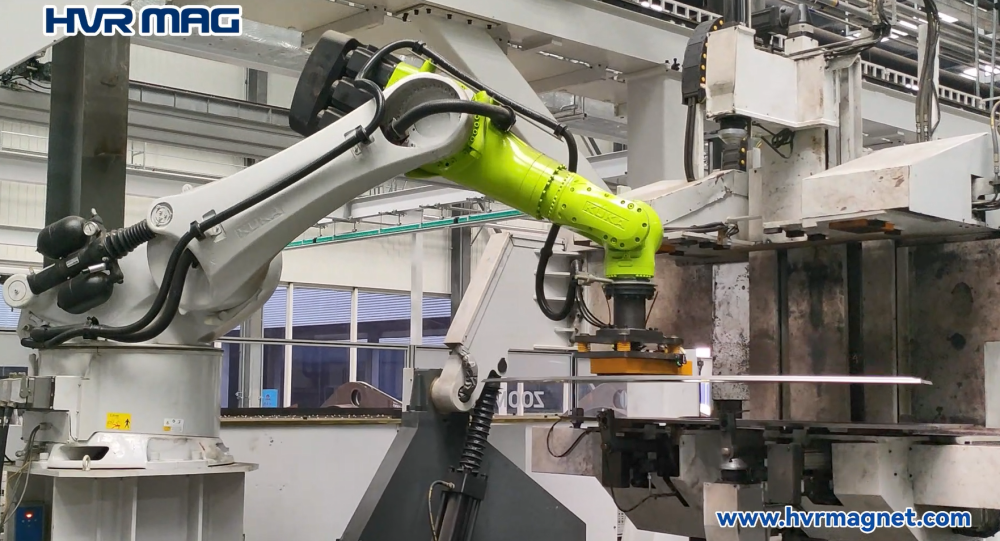

In modern manufacturing environments, the integration of specialized equipment with robotic systems represents a significant step forward in operational efficiency. Our electro-permanent magnetic workholding systems are engineered specifically for seamless integration with industrial robotic arms, creating a versatile solution for material handling applications across various industries.

Technical Principles and System Integration

Electro-permanent magnet technology utilizes controlled electrical pulses to generate and maintain a powerful magnetic field without continuous power supply. This fundamental characteristic makes it particularly suitable for robotic applications where reliability and energy efficiency are paramount. The system’s interface is designed to communicate directly with robotic controllers, allowing for synchronized operation and precise positioning. This integration enables manufacturers to incorporate magnetic workholding into their automated production lines with minimal modification to existing robotic setups.

Application Versatility and Workpiece Compatibility

The system demonstrates remarkable adaptability across different manufacturing sectors. In metal fabrication, it securely handles precisely machined components with complex geometries. Automotive production lines utilize these systems for transferring stamped body panels between stations. The technology equally serves the appliance industry for moving sheet metal cabinets and the aerospace sector for positioning structural components. This versatility extends to workpiece materials as well, effectively handling various ferromagnetic materials including carbon steel, alloy steel, and specific grades of stainless steel.

Operational Advantages in Automated Environments

The implementation of magnetic workholding in robotic systems addresses several challenges inherent in traditional material handling methods. The absence of mechanical clamps or vacuum systems eliminates obstruction around the workpiece, allowing for unimpeded access during processing operations. The system’s rapid magnetic switching capability, typically requiring less than one second for full engagement or release, aligns perfectly with the high-cycle demands of automated production. Furthermore, the non-contact holding method preserves surface integrity by eliminating mechanical stress and minimizing particulate generation.

Engineering Considerations for Implementation

Successful implementation requires careful consideration of several technical parameters. The magnetic system must be appropriately sized according to the robotic arm’s payload capacity and the specific characteristics of the workpieces. Factors such as material thickness, surface condition, and geometry significantly influence holding performance. Safety remains paramount, with integrated monitoring systems continuously verifying magnetic status and providing real-time feedback to the robotic controller. Backup power systems ensure maintained holding force during unexpected power interruptions, while redundant monitoring circuits provide additional operational security.

Future Development Directions

Current research focuses on enhancing the adaptability and intelligence of magnetic workholding systems. Developments include pressure-sensitive magnetic arrays that automatically adjust holding force according to workpiece weight and profile. Advanced sensor integration enables real-time monitoring of workpiece position and orientation during transfer. These innovations aim to further bridge the gap between conventional workholding and the evolving requirements of smart manufacturing environments, contributing to more responsive and flexible production systems.

This technical overview presents the fundamental characteristics and implementation considerations of robotic-integrated magnetic workholding systems, providing manufacturers with substantive information for evaluating their potential application in automated manufacturing processes.