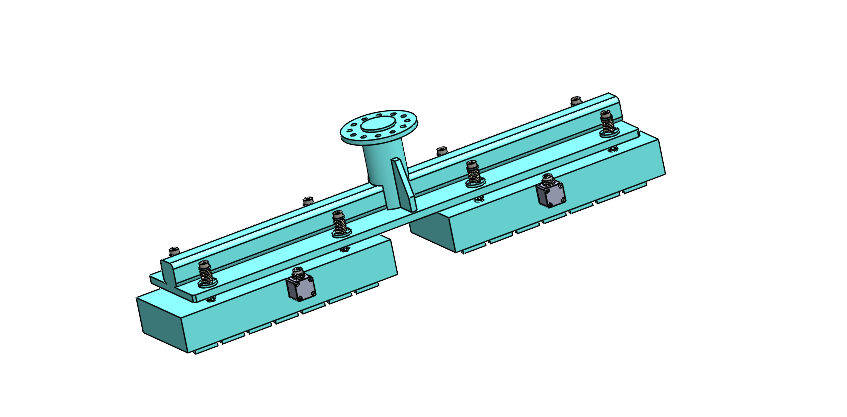

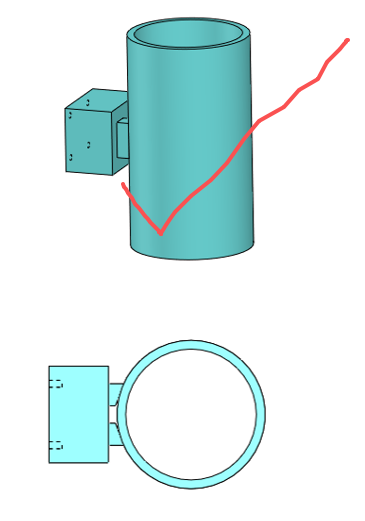

We recently worked with a client to develop a magnetic gripper for steel cylinders ranging from 219mm to 406mm in diameter and 650mm to 2500mm in length. These cylinders have wall thicknesses of 4mm to 15mm and weigh between 50kg and 350kg.Many industrial applications require handling cylindrical objects, where traditional gripping methods often struggle with secure contact and adaptability.https://www.hvrmagnet.com/

Technical Configuration and magnetic gripper Selection

Our solution uses two HEPMT-4718A electro-permanent magnetic units, each providing 180kg of lateral gripping force. We position these magnets to align perfectly with the curved surface of the cylinders, ensuring uniform contact and optimal force distribution. The combined gripping capacity comfortably handles the maximum workpiece weight while maintaining a substantial safety margin.

Operational Workflow and Motion Requirements

The magnetic gripper system operates as part of a handling mechanism that executes a 90-degree rotation after attachment. Throughout this angular transition, the magnetic units maintain secure contact, effectively resisting both gravitational and dynamic forces. The electro-permanent technology ensures consistent holding force without needing continuous power, guaranteeing reliability during the complete rotation cycle.

Safety and Performance Considerations

Our design successfully addresses the challenges of curved surface attachment and rotational dynamics. The selected magnetic units perform effectively across the entire thickness range from 4mm to 15mm. This application demonstrates how magnetic gripping technology can adapt to non-flat surfaces and dynamic handling requirements in industrial environments.

This practical implementation shows how specialized magnetic gripper solutions can solve specific geometric and operational challenges in modern manufacturing facilities.