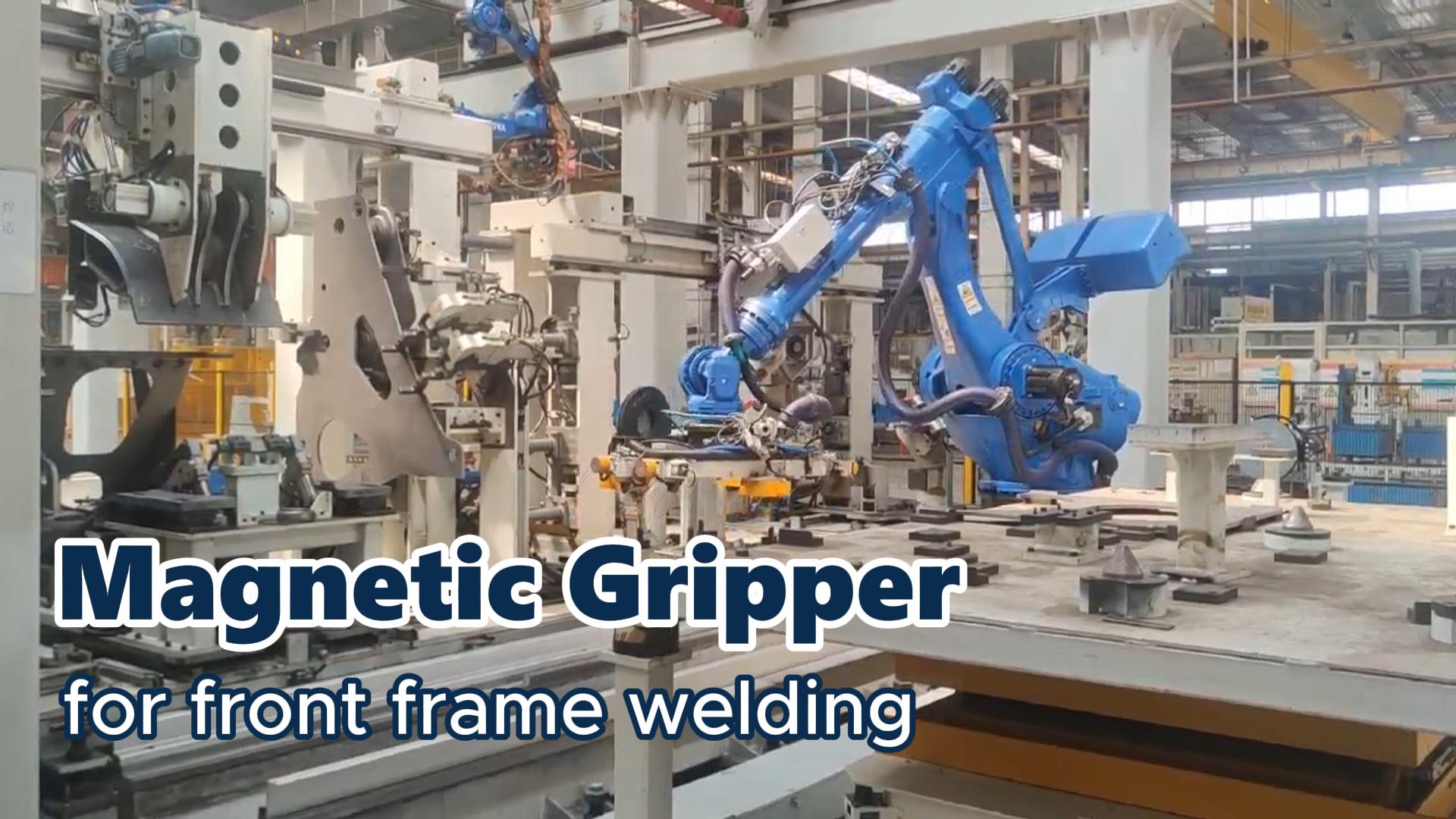

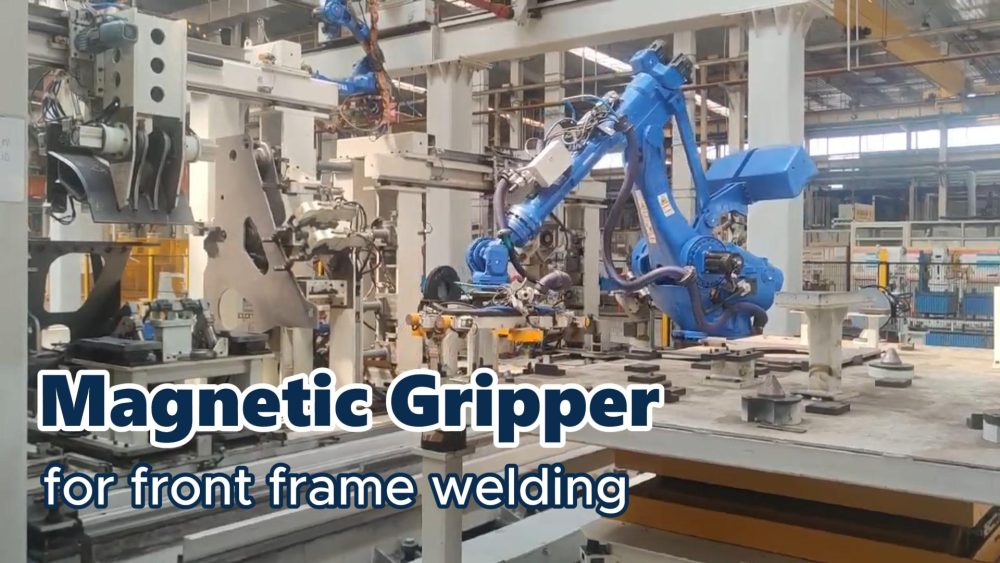

In modern manufacturing, robotic welding cells require reliable tooling to maintain consistent production quality. Our magnetic gripper offers a practical solution for handling ferromagnetic workpieces in automated welding environments. Designed to integrate with industrial robotic arms, this tool simplifies the process of positioning and securing metal components during welding operations.

Key Features and Benefits

The gripper utilizes electro-permanent magnet technology, which requires energy only during the pick-up and release phases. This design eliminates the need for continuous power supply, reducing energy consumption and minimizing heat generation in the workspace. Its compact structure allows seamless integration with most industrial robotic arms, providing flexibility in handling various workpiece geometries.

With a focused magnetic field distribution, the gripper ensures stable clamping without interfering with nearby electronic equipment or the welding process itself. The absence of pneumatic components or mechanical clamps simplifies maintenance and decreases the risk of contamination from debris or sparks.

Application in Welding Processes

In robotic welding applications, precise workpiece positioning is critical to achieving high-quality results. The magnetic gripper enables rapid loading and unloading of components, reducing non-productive time in the welding cycle. Its design accommodates flat or curved surfaces, making it suitable for welding assemblies ranging from structural frames to fabricated metal parts.

The non-contact holding mechanism minimizes surface contact, reducing the risk of scratches or damage to finished surfaces. This is particularly valuable when handling pre-finished or coated materials. Additionally, the gripper’s compatibility with programmable logic controllers (PLCs) allows for synchronized operation with the welding robot, supporting streamlined automation.

Technical Considerations

When integrated into a robotic welding system, the magnetic gripper contributes to process repeatability and operational safety. Its fail-safe mechanism ensures workpieces remain securely held even in the event of power loss. For optimal performance, workpiece material properties such as thickness, surface condition, and permeability should be evaluated during system design.

This magnetic gripper exemplifies our focus on developing functional components that address specific industrial challenges. By providing a reliable method for handling metal parts in robotic welding, it supports manufacturers in achieving efficient and consistent production outcomes.