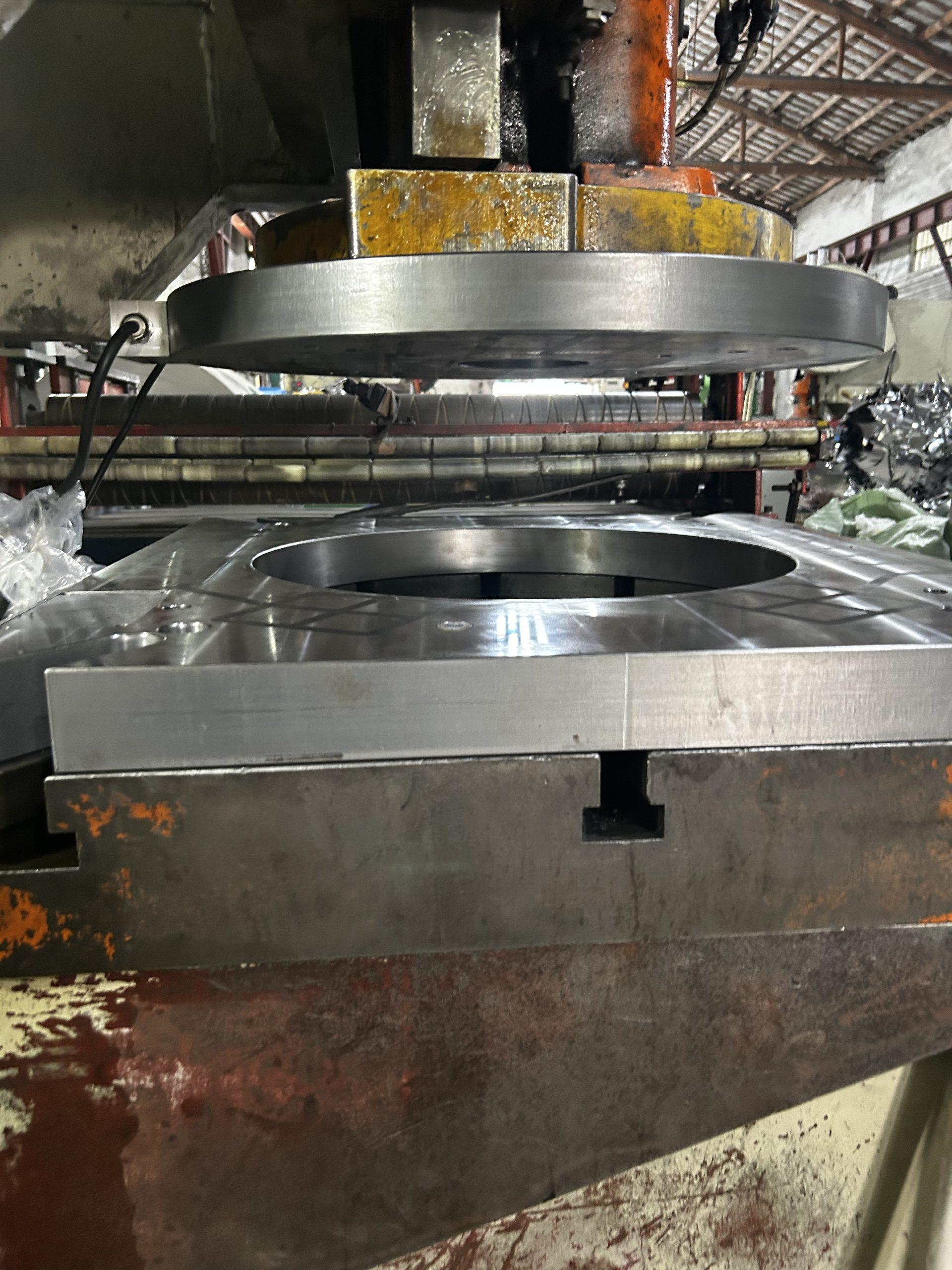

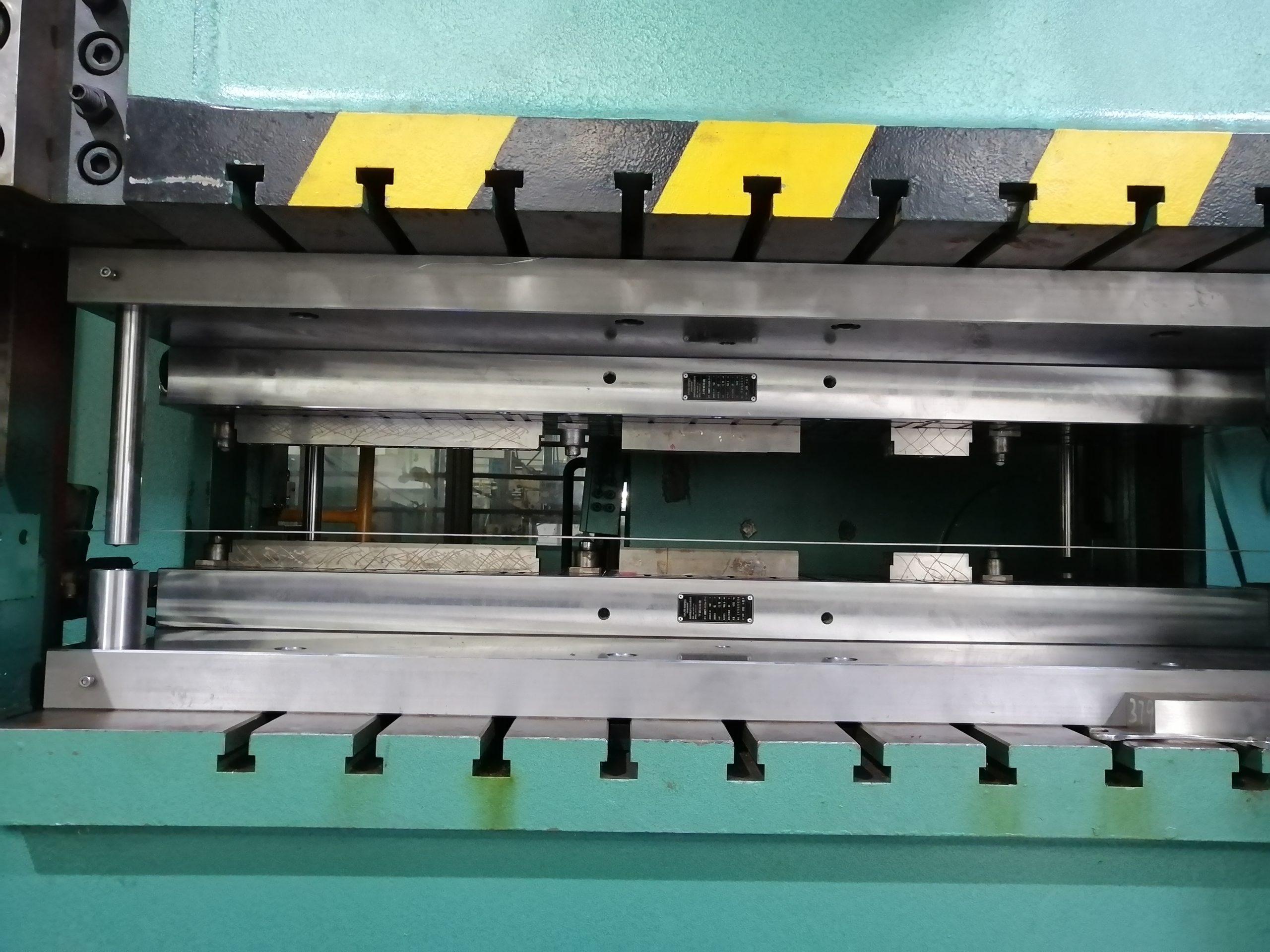

Magnetic Quick Die Change System for Stamping Press

The magnetic quick die change system is designed to accommodate dies of any shape and size. Existing dies can be seamlessly integrated into any stamping press equipped with the quick die change system without the need for modifications.

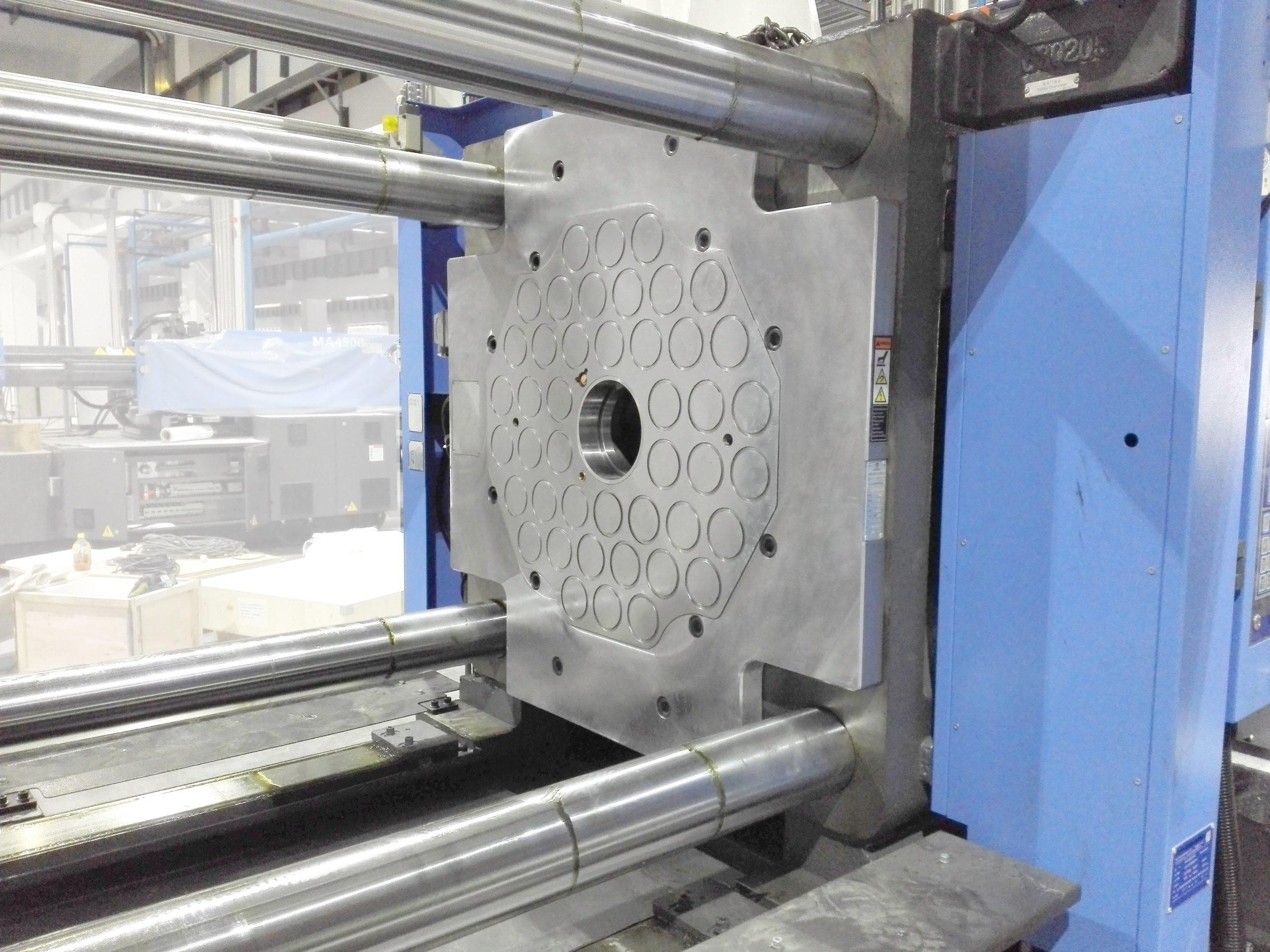

8 Safety Measures of Magnetic Quick Die Change System

The MAG cycle can only be performed when the mold is stably suctioned by magnetic platen.

During the injection molding process, if the magnetic flux value decreases, the machine stops immediately.

High temperatures reduce magnetic force; sensors halt production if the preset temperature is exceeded.

Current pulses are monitored during MAG/DEMAG cycles; successful release is reported only at set value.

Mold position is monitored; slight movement stops the machine.

Proximity switch ensures DEMAG cycle only if distance <0.2 mm; production stops if distance >0.2 mm.

Automatic injection program can be initiated only if sensors are normal, platens magnetized, and safety key is in position. Any other conditions trigger an alarm and stop the operation.

Safety key selects setup or injection mode. Demagnetize requires pressing LOCK and DEMAG simultaneously. DEMAG is unavailable during production.

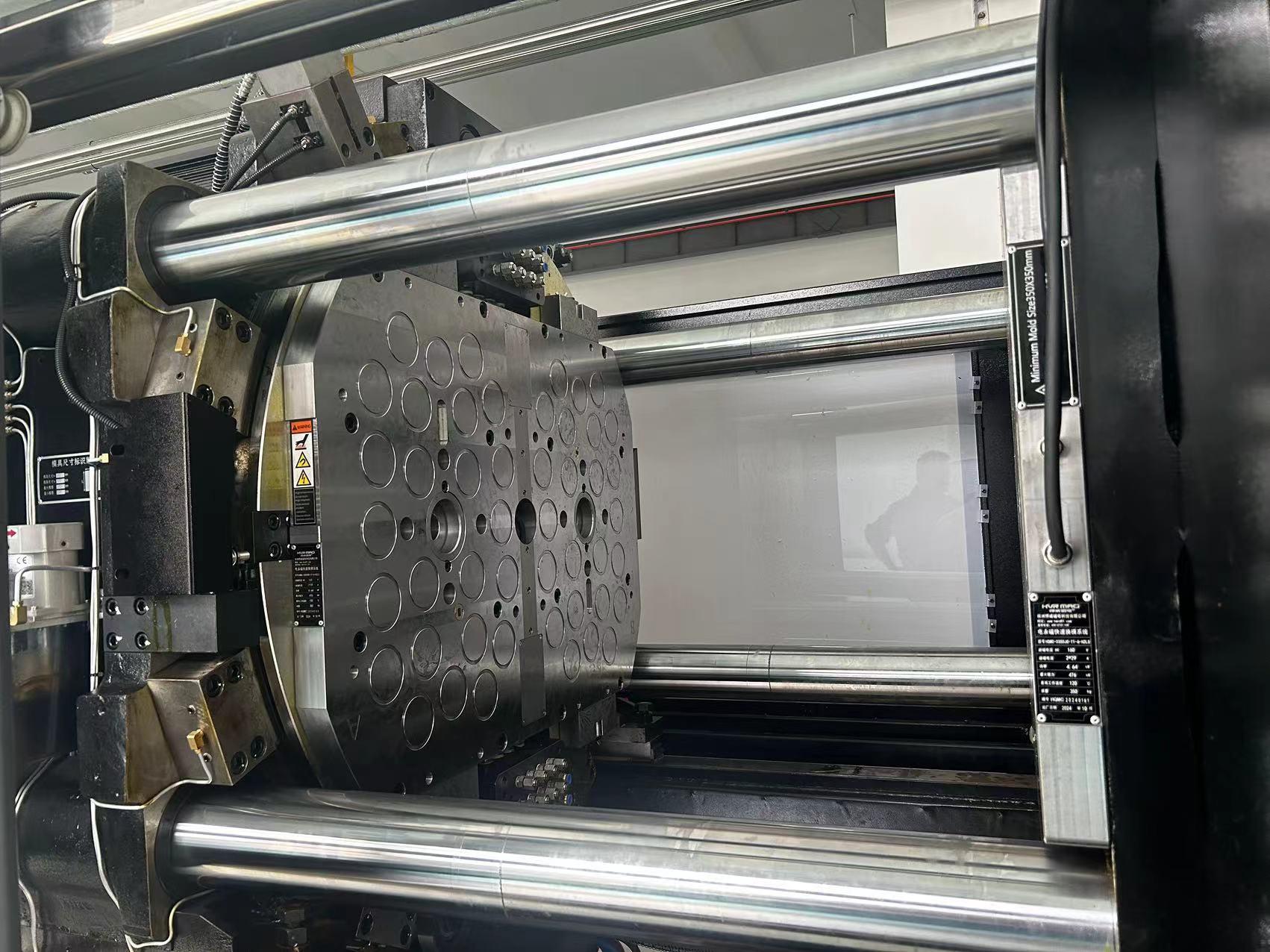

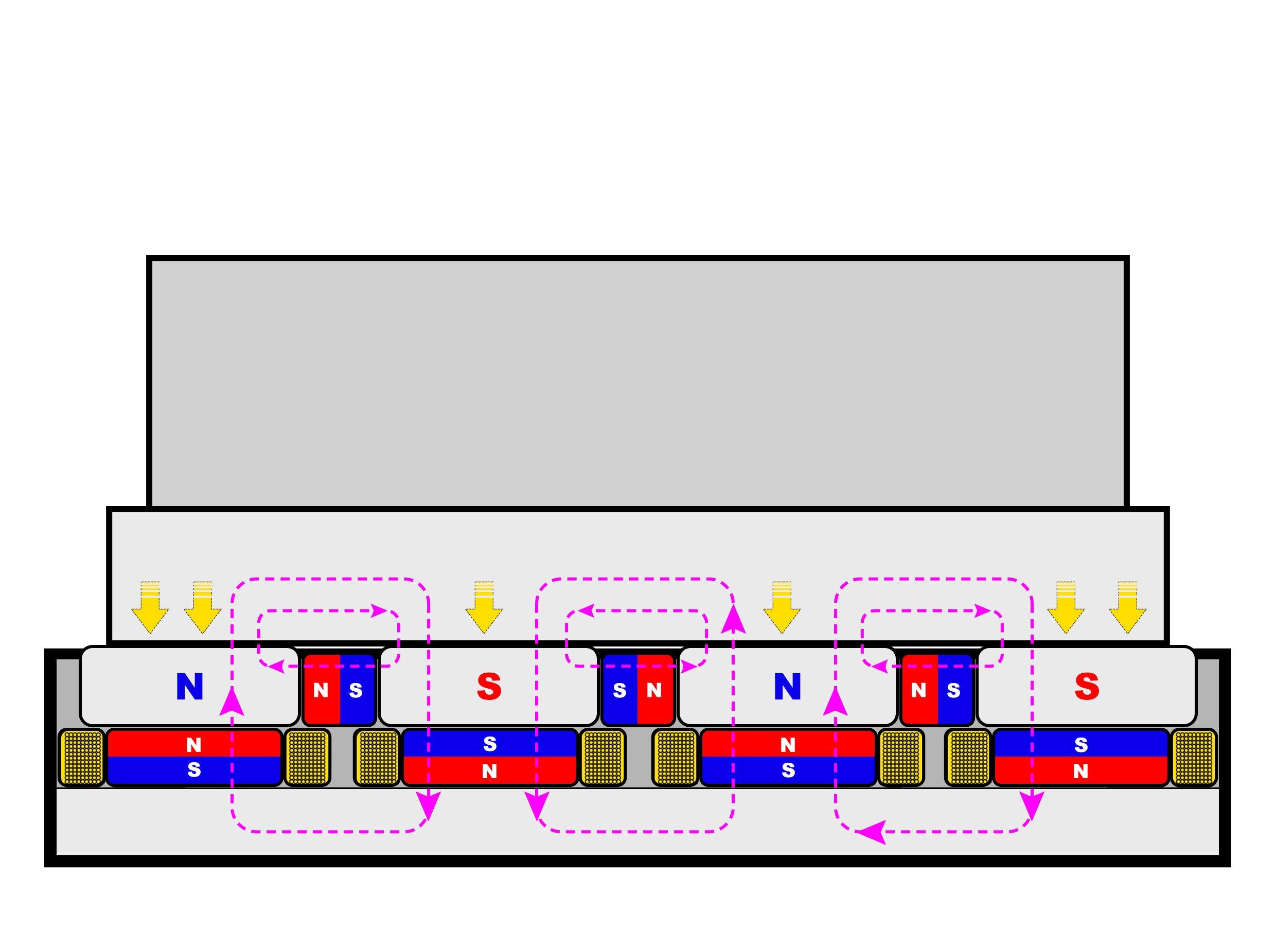

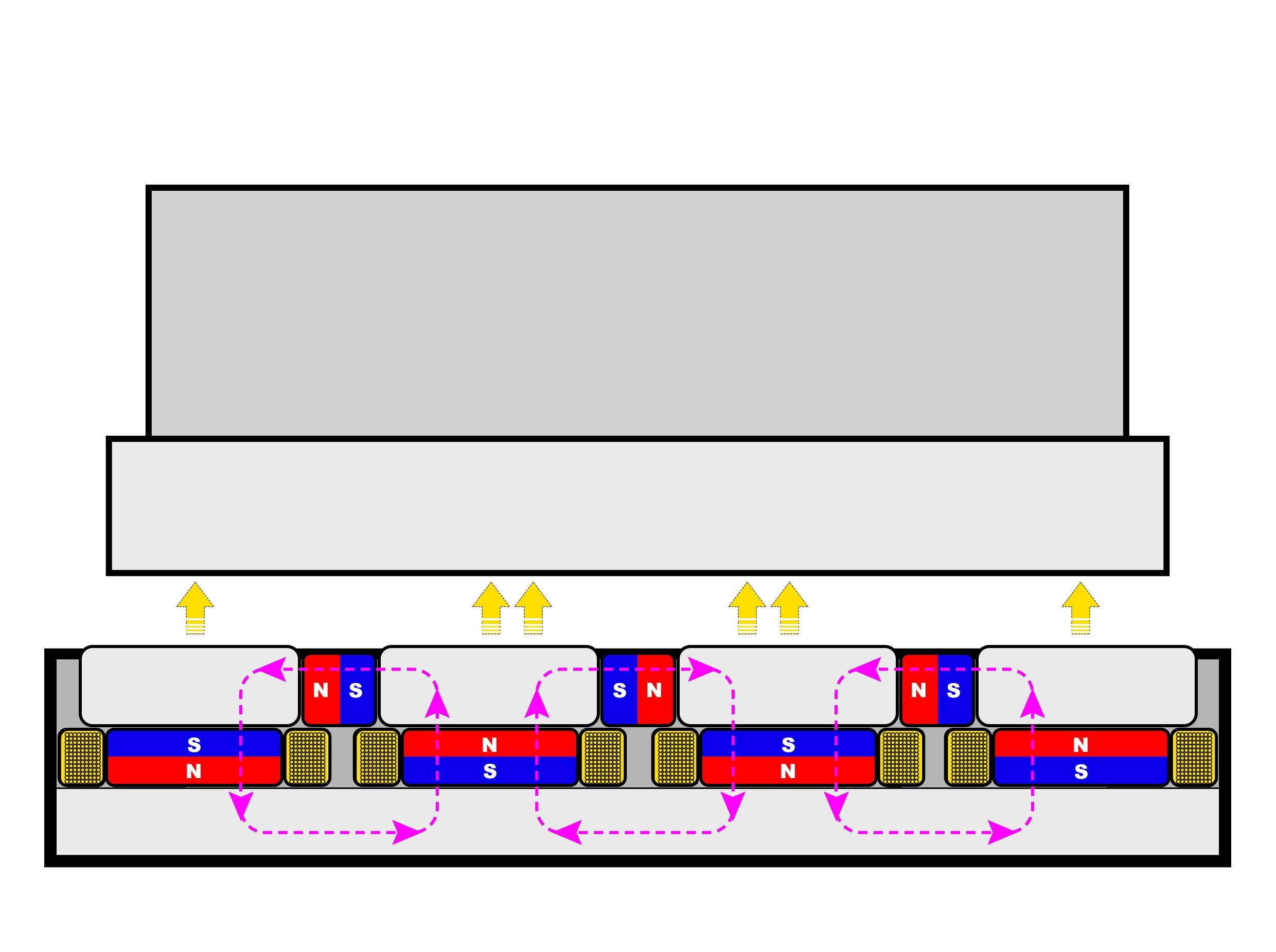

Working Principle of Magnetic Planten for Quick Die Change on Punch Press

- An excitation current is passed through the solenoid coil for 0.1-0.5s

- Neodymium magnet and AlNiCo magnet become unipolar

- The magnetic poles form a magnetic circuit with the mold and clamping the mold

1.An excitation current is passed through the solenoid coil for 0.1-0.5s

2.Pole of AlNiCo magnet is inverted

3.Magnetic Flux of Neodymium magnet and Alnico magnet is not emitted from the surface of the magnet core. Thus, it unclamps the mold.