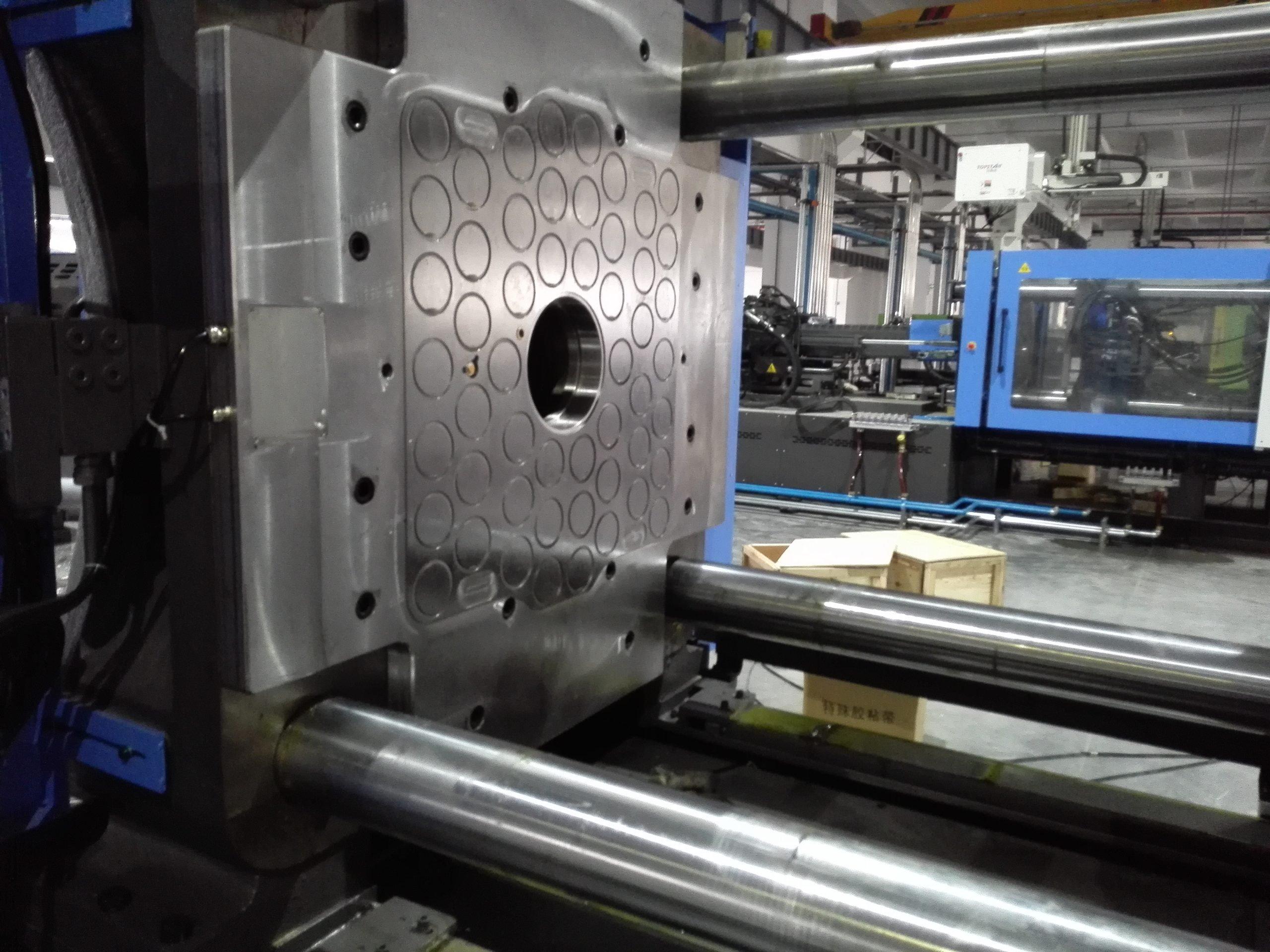

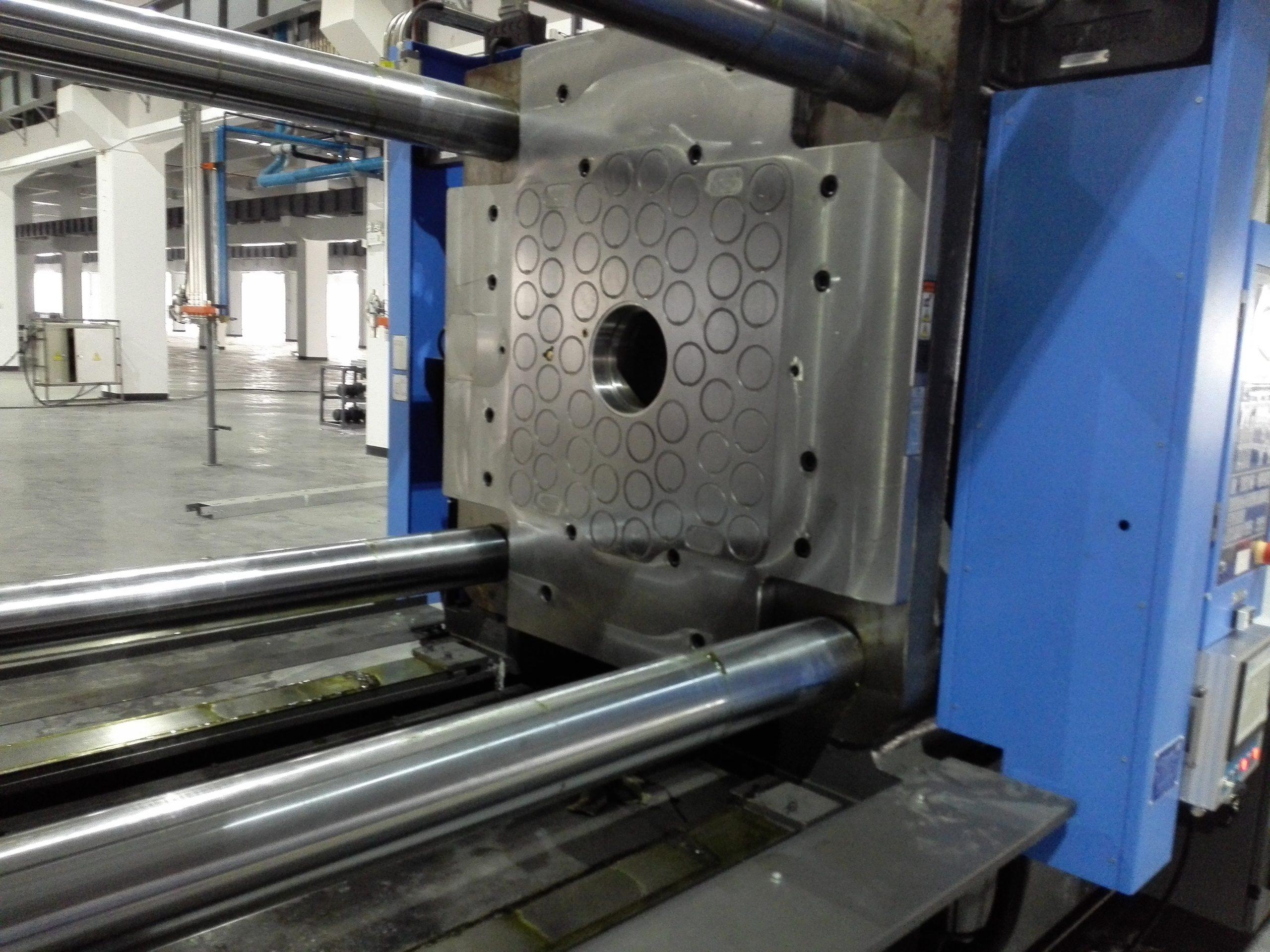

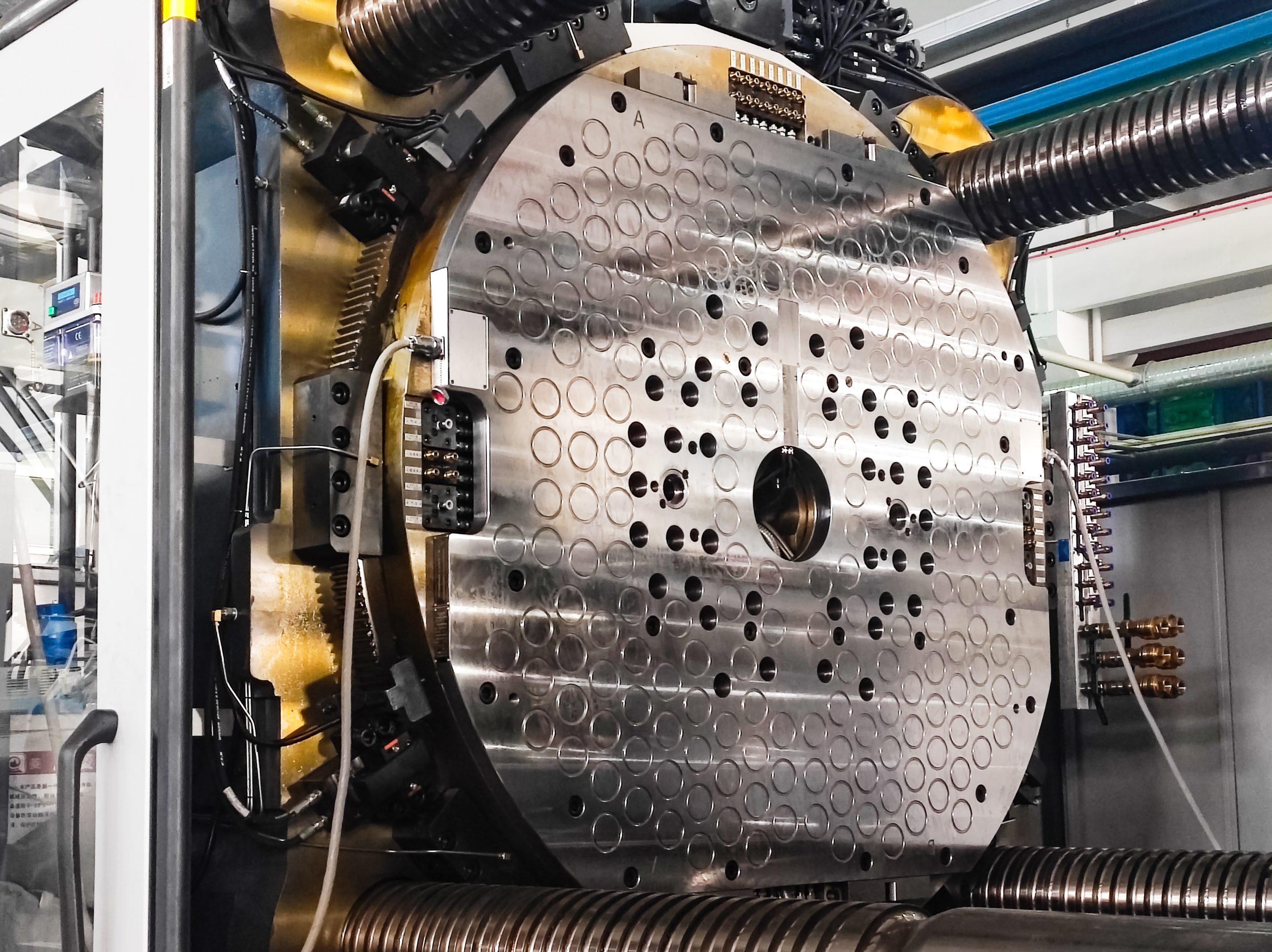

Magnetic Platen for Injection Molding Machine

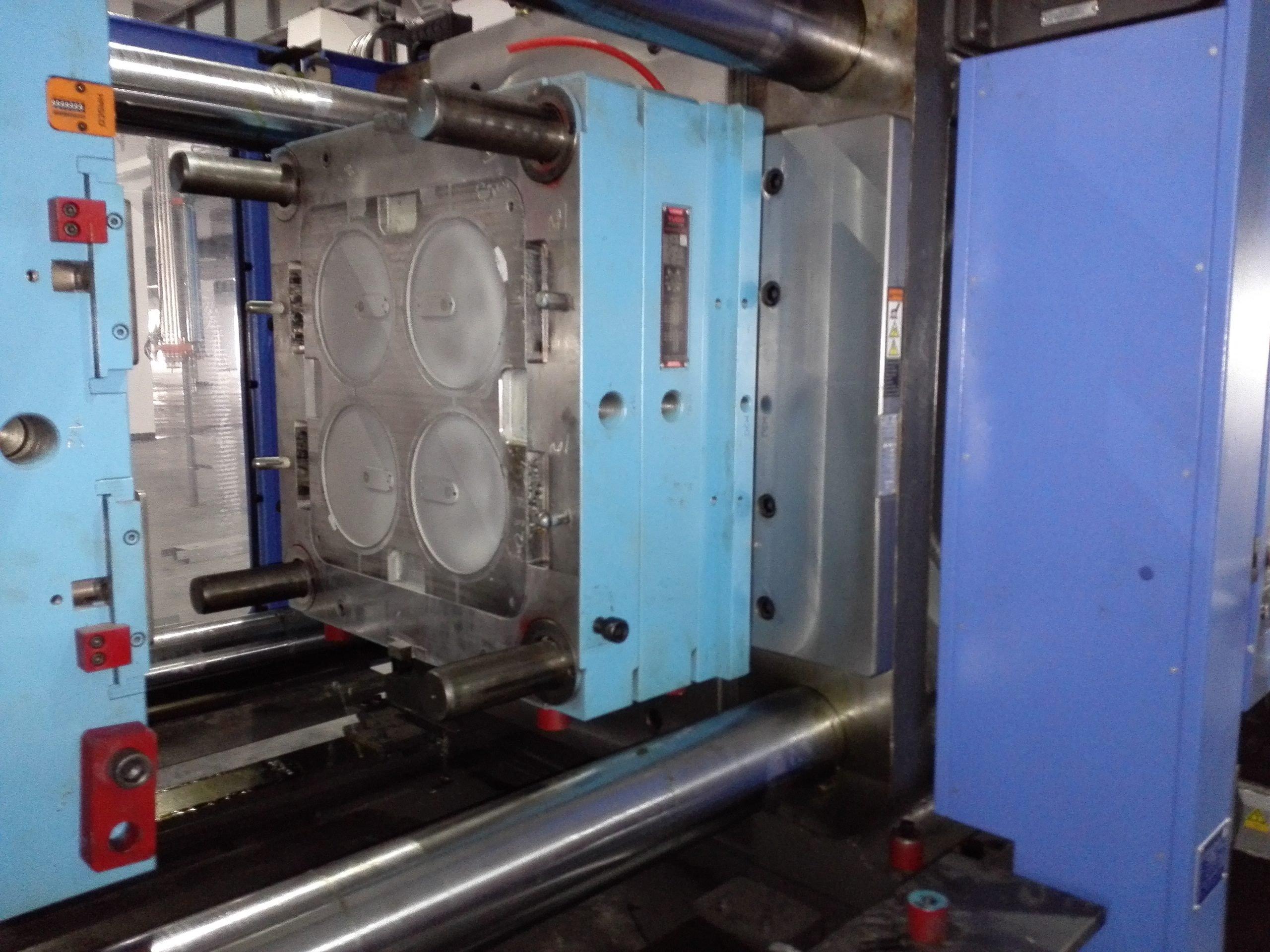

When formats need to change often, it’s important to change molds quickly. HVR magnetic quick mold change system makes this process easy. It supports mold changeover in only 3 minutes for each clamping unit, with no tools and no special mold carriages needed.

8 Safety Measures of Magnetic Quick Mold Change System

The MAG cycle can only be performed when the mold is stably suctioned by magnetic platen.

During the injection molding process, if the magnetic flux value decreases, the machine stops immediately.

High temperatures reduce magnetic force; sensors halt production if the preset temperature is exceeded.

Current pulses are monitored during MAG/DEMAG cycles; successful release is reported only at set value.

Mold position is monitored; slight movement stops the machine.

Proximity switch ensures DEMAG cycle only if distance <0.2 mm; production stops if distance >0.2 mm.

Automatic injection program can be initiated only if sensors are normal, platens magnetized, and safety key is in position. Any other conditions trigger an alarm and stop the operation.

Safety key selects setup or injection mode. Demagnetize requires pressing LOCK and DEMAG simultaneously. DEMAG is unavailable during production.

Specifications & Configurations

| HQMC Technical characteristics | ||

| IMM capacity(Ton) | ≤200 Ton | ≥200 Ton |

| Dimension of Magnetic Pole (mm) | 44 | 66 |

| Magnetic Force/ Pole (Kg) | 350 | 900 |

| Plate Thickness (Single Side) | 35mm | 46mm |

| Max.Operating Temperature (℃) | 120℃/150℃/180℃ | |

| Magnetic Flux Depth (mm) | 20mm | |

| Mold Proximity Sensor Range (mm) | 0.2mm | |

| Standard Voltage | AC220V/380V/415V/440V,50/60Hz | |

| Ejector Holes | Standard | |

| Centering Rings | Standard | |

| Temperature Sensor | Standard | |

| Proximity Sensor | Standard | |

| Magnetic Flux Sensor | Standard | |

| Die dislocation Detection | Standard | |

| Magnetic Current Detection | Standard | |

| Pole Sealing | Metal | |

| Machine Integration | EUROMAP 70.0/70.1 | |