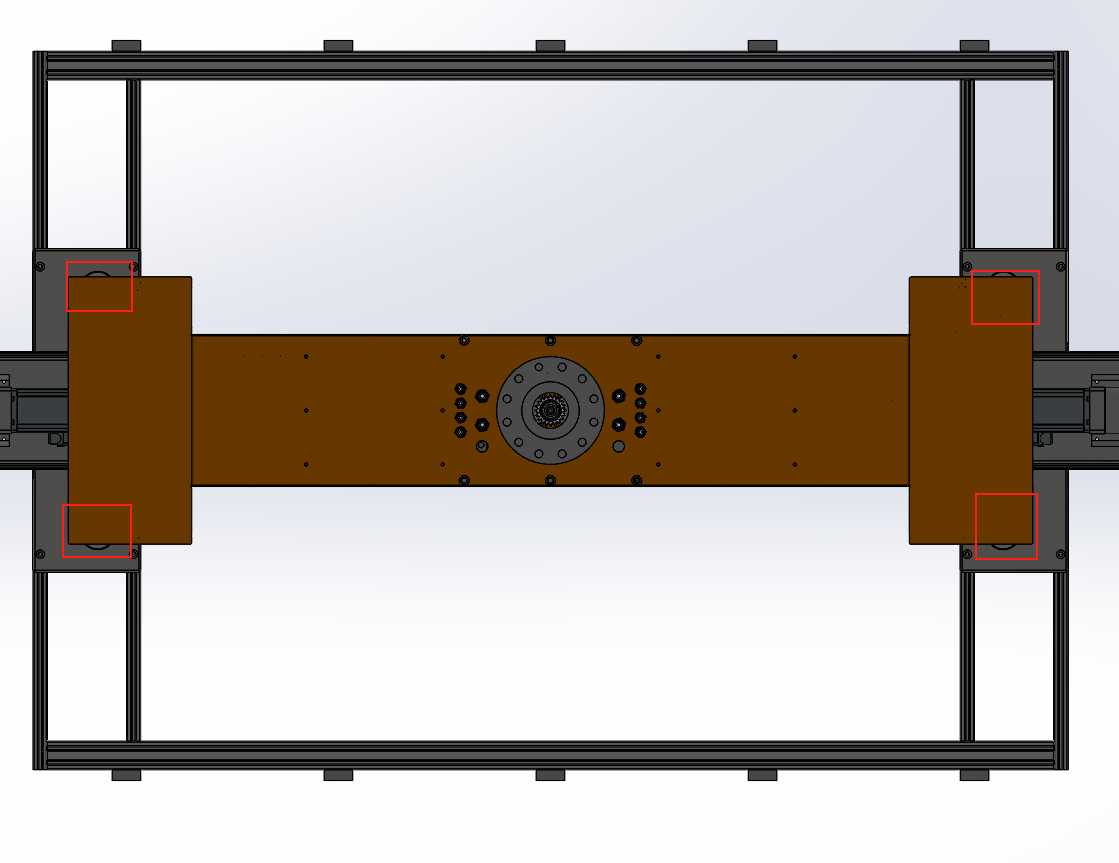

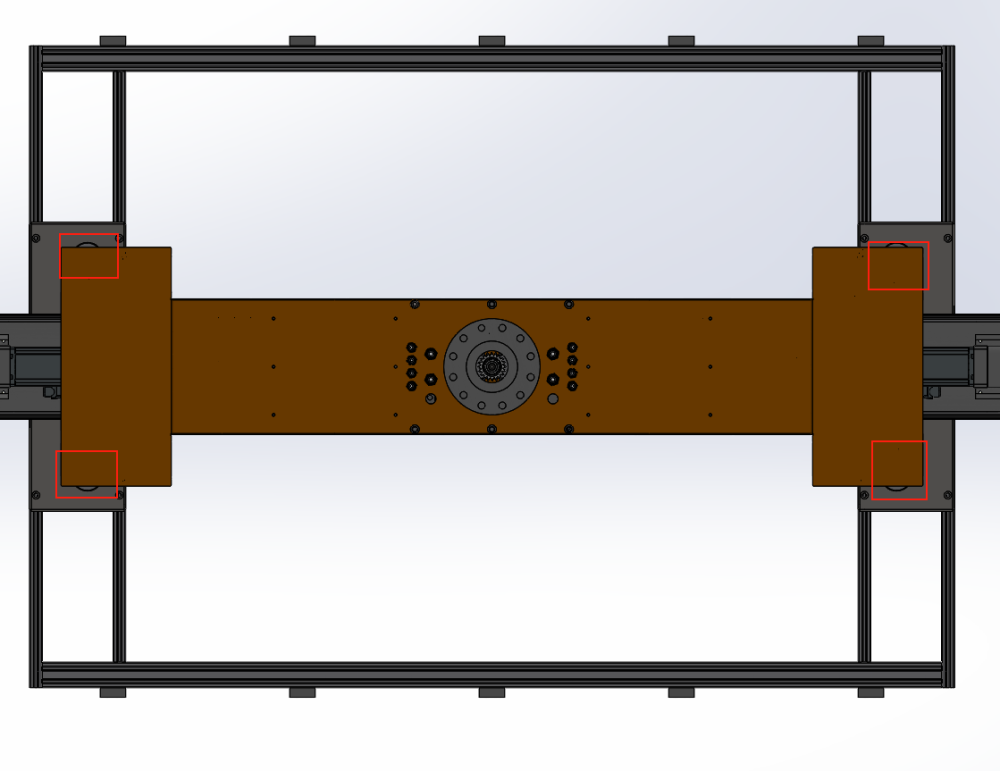

In modern manufacturing and logistics operations, the efficient handling of standardized pallets remains a fundamental requirement for streamlined workflow. We recently collaborated with a client to develop a specialized magnetic workholding solution for handling 1440×1000mm pallets with a total maximum load of 80kg. The technical requirements specified attachment points limited to the steel plates located on both sides of the pallet structure.

Technical Approach and Component Selection

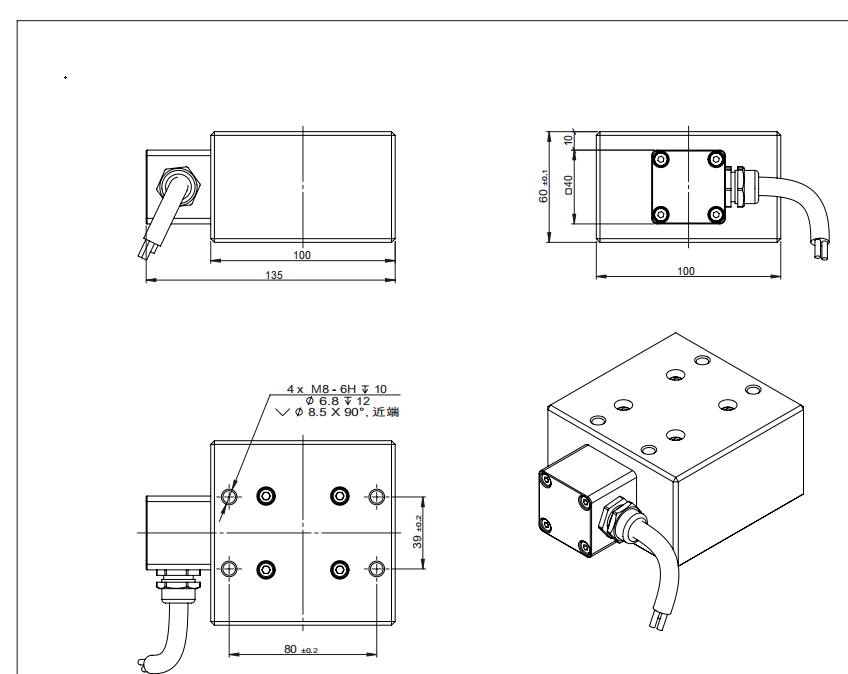

The engineered solution utilized four HEPMP-100H electro-permanent magnetic units, strategically positioned to ensure balanced force distribution across the pallet’s available contact surfaces. Each magnetic unit provides a holding force of 100kg, creating a total theoretical capacity of 400kg for the system. This specification was determined through careful analysis of both the static and dynamic forces encountered during typical handling operations.

Safety Considerations and Performance Parameters

The implemented design incorporates a 4:1 safety factor, significantly exceeding standard industry requirements for such applications. This substantial safety margin accounts for potential acceleration forces, uneven load distribution, and other variables that may occur during transfer operations. The electro-permanent magnet technology ensures maintained holding force without continuous power supply, providing an additional layer of operational safety.

System Integration and Operational Workflow

The four magnetic units operate in synchronized configuration, engaging and disengaging simultaneously to ensure stable and secure pallet handling. This coordinated operation prevents tilt or shift during movement, maintaining load integrity throughout the transfer process. The control system interfaces seamlessly with existing handling equipment, requiring minimal modification to the client’s current operational infrastructure.

This application demonstrates how magnetic workholding technology can be adapted beyond traditional plate handling to address specific material handling challenges in industrial environments. The solution highlights the importance of proper safety factoring and system design in developing reliable material handling systems.