Recently, we designed a special magnets for automation system for our customer in India market. They have the requirement for Magnetic Gripper, and they need to move high-temperature steel plates (with workpiece temperatures reaching up to 350-400 degrees) by robot arm in their automation line.https://hvr-magnet.com/

There are the dimension of the steel plates and their challenges:

- Component Weight – 120 Kg

- Component SIze – 2400 mm L X 300mm W minimum Length -1600mm

- Sheet Thickness – 0..8- 7 mm

- Application – Handling

- Challenges — Component may twist by shearing machine

Component Temperature high up to 350-400 degree

- Metal Composition — Carbon Content ( 0 – 0.97 %)

Robot make -Kuka KR240 kg

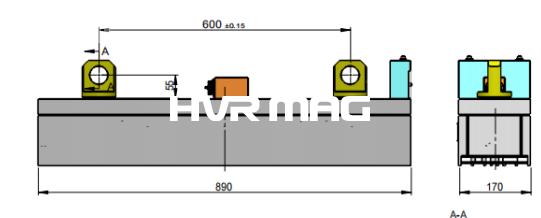

They intend to lift the plate by using magnetic gripper on robot,Just pick and place,and keep it at a platform, that’s easy for us. But the challenge is the High Temperature. According to their requirement and working condition, we suggested their to use our magnetic system with Water Cooling System to overcome the high temperature.

The Results: The implementation of this solution brought about several significant benefits:

Safety First: The elimination of manual handling reduced the risk of injuries to workers, creating a safer working environment. The water cooling system also minimized the risk of overheating and potential hazards.

Increased Efficiency: The automated handling system decreased the time required for each lift, resulting in improved productivity and throughput. The water cooling system allowed for continuous operation without the need for frequent breaks to cool the plates.

Cost Savings: The reduction in labor costs, along with increased productivity and reduced equipment maintenance, led to significant cost savings for the customer. The water cooling system also helped to extend the lifespan of the equipment.

Versatility: The system’s adaptability allowed it to handle various plate sizes and shapes, providing flexibility for future production needs. The water cooling system could be adjusted to meet the specific cooling requirements of different plates.

The combination of our electro-permanent magnet, robot automation line, and water cooling system proved to be a game-changer, providing a safe, efficient, and cost-effective solution for handling hot steel plates. We are proud to have delivered value to our customer and look forward to helping more industries achieve similar success.