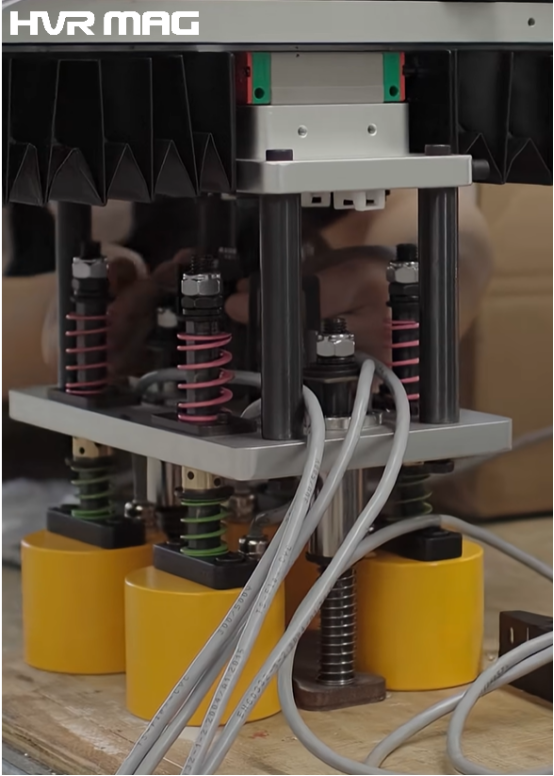

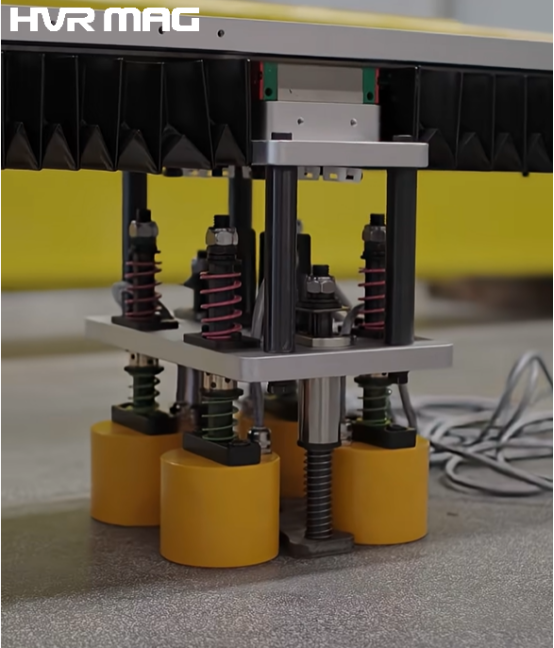

Em HVR MAG, we develop electro-permanent magnetic solutions that integrate directly with automated equipment and support stable material handling in modern factories. This project shows our sistema magnético de fixação de trabalho during installation on an automated gantry. The photos capture the integration stage as technicians mount and align the magnetic units for accurate daily operation.

Round electro-permanent magnets:

The system uses four round electro-permanent magnets as one working group. This configuration delivers strong and balanced magnetic force during lifting. After installation, the gantry grips, transfers, and positions metal workpieces with smooth and precise motion. The magnetic approach removes the need for mechanical clamps and complex fixtures, which simplifies the equipment structure and lowers maintenance effort.

Magnetic workholding system advantages:

Electro-permanent technology brings practical energy advantages. The magnets consume power only during magnetization and demagnetization, while the holding force remains stable without continuous electricity. This feature supports efficient operation and improves process safety. When paired with programmed gantry movements, the system achieves repeatable pick-and-place cycles and consistent positioning accuracy.

By integrating the magnetic workholding solution directly into the gantry equipment, customers achieve faster handling cycles and more stable workflow. The grouped magnetic layout allows flexible adaptation to different workpiece sizes while maintaining reliable gripping strength. As a result, overall production efficiency increases significantly, and manual intervention is greatly reduced.

This installation demonstrates how electro-permanent magnetic technology can become a core component of automated handling systems. Through practical design and seamless integration, HVR MAG helps manufacturers build efficient, precise, and dependable production lines.