In the field of injection molding, efficiency and precision are paramount, especially when it comes to two color injection molding machine. These machines are designed to inject two different materials into a single mold. It creates complex and high-quality parts in one process. However, the process of changing molds is a critical factor that can significantly impact overall production efficiency. Traditionally, hydraulic quick mold change systems have been employed. But, there is an increasing shift towards magnetic quick mold change systems, particularly for two color injection molding machine.

Mold Change Challenges on Two Color Injection Molding Machine

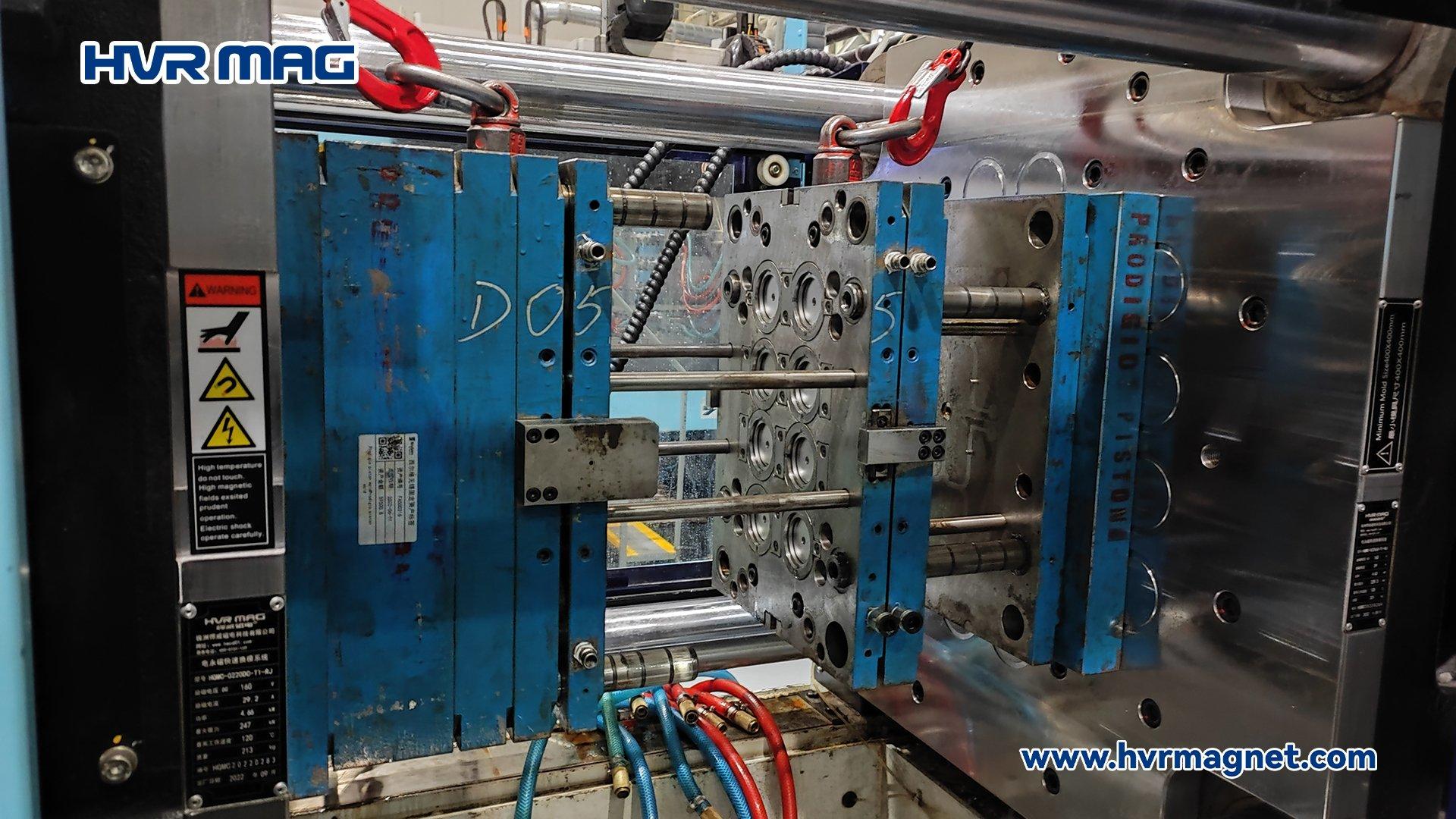

Hydraulic quick mold change systems have long been favored in many injection molding applications due to their robust performance and reliability. They utilize hydraulic clamping mechanisms to securely hold the mold in place. However, this approach presents specific challenges when applied to two color injection molding machine.

One significant issue is related to the complexity of the hydraulic systems involved. In two color injection molding, the mold needs to rotate between the two injection stages. This rotation can cause the hydraulic lines that supply the clamping devices to bend and flex. Over time, these hydraulic lines are susceptible to leakage, which not only compromises the system’s integrity but can also lead to costly downtime and maintenance.

Magnetic Quick Mold Change Systems: A Superior Alternative

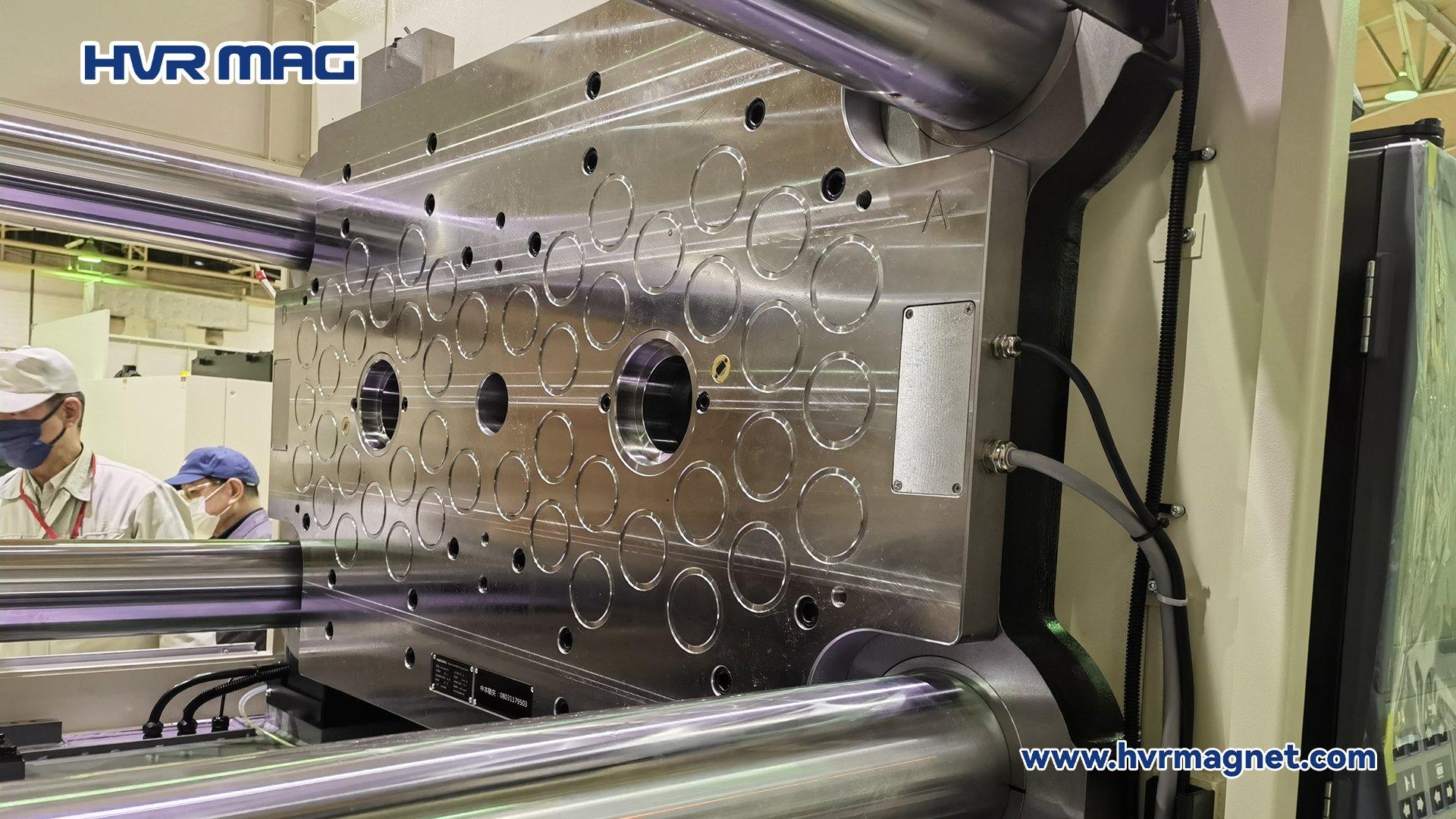

Magnetic quick mold change systems offer a compelling alternative to hydraulic systems, especially for two color injection molding machine.

- Elimination of Hydraulic Lines:Magnetic systems rely on powerful magnets to secure the mold in place, eliminating the need for hydraulic lines and clamps. This absence of hydraulic components reduces the risk of leaks and mechanical failures associated with hydraulic systems.

- Enhanced Reliability:Without the complexities and potential issues of hydraulic fluid, magnetic systems offer improved reliability. They provide consistent and precise mold clamping without the risk of hydraulic pressure fluctuations or fluid leakage.

- Simplified Maintenance:The absence of hydraulic components means there are fewer parts that require regular maintenance or replacement. This simplifies the overall maintenance process and reduces associated costs.

Conclusion

While magnetic quick mold change systems may come with a higher initial investment compared to hydraulic systems, their benefits far outweigh the costs, particularly in the context of two color injection molding machines. By addressing the challenges associated with hydraulic systems, such as potential leaks and maintenance issues, magnetic systems provide a more reliable, efficient, and cost-effective solution for modern injection molding needs. As the industry continues to evolve, adopting magnetic quick mold change systems represents a smart move towards enhancing productivity and maintaining high-quality standards in two color injection molding.