What is SMED?

SMED stands for Single-Minute Exchange of Die. It is a groundbreaking lean manufacturing technique that originated in Japan in the early 1950s. SMED aims to minimize setup times to less than 10 minutes, ideally achieving a single-digit minute setup time. SMED was initially employed in automotive manufacturing. It enabled Toyota to reduce product changeover times from four hours to a mere three minutes.

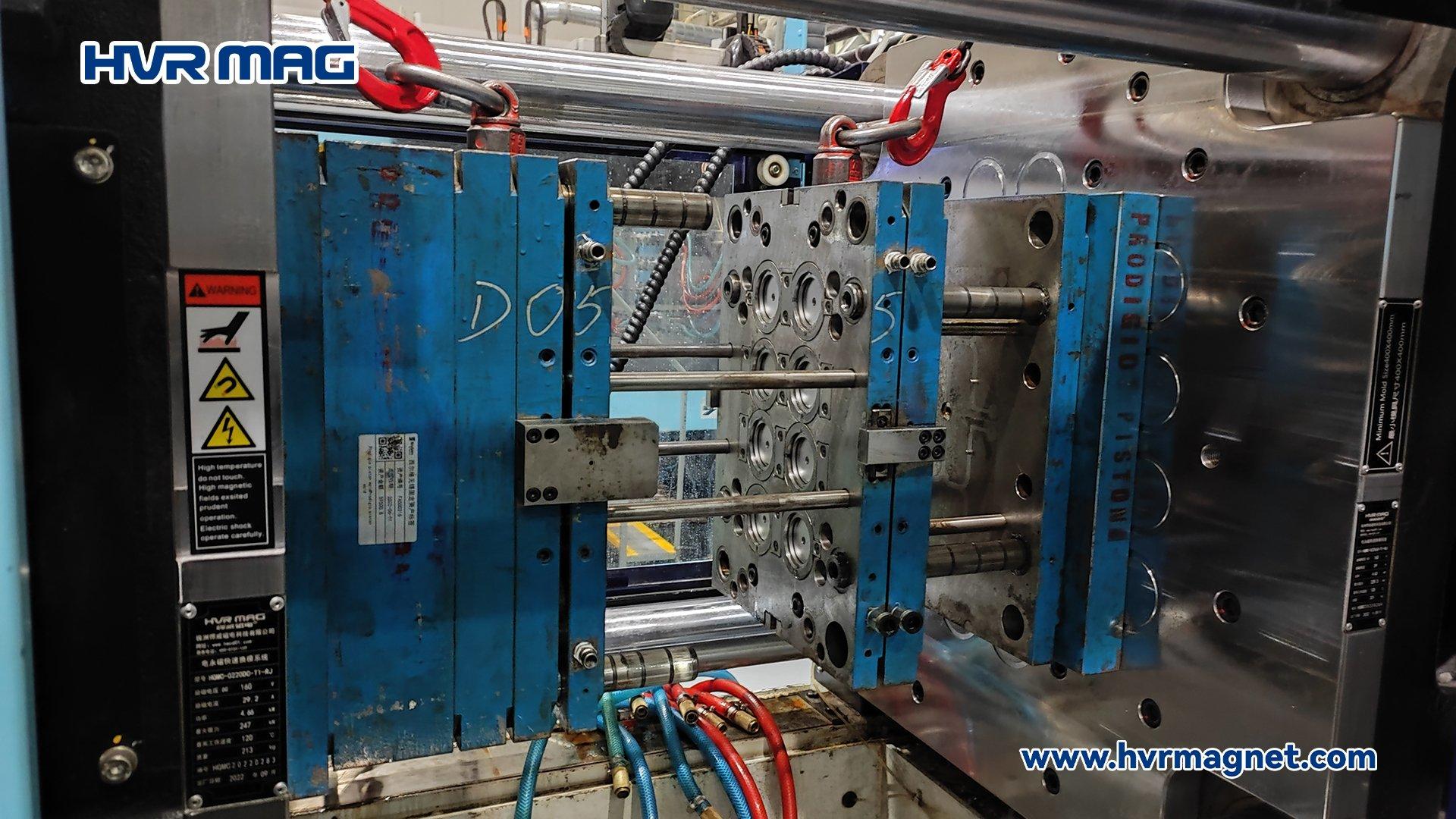

These days, competition is getting tougher – especially in car and plastic parts manufacturing. Products don’t last as long in the market anymore, and customers want more different types of products. That’s why factories need to be able to switch between different production setups super fast. Quick mold change systems have emerged as a crucial component of SMED, particularly in plastic injection molding.

Equipment for Quick Mold Change: Enhancing Efficiency and Flexibility

In the realm of plastic injection molding, the rapid evolution of products and the proliferation of product variants have necessitated frequent mold changes. This increased frequency of mold changes leads to significant downtime, adversely impacting production efficiency and machine utilization rates. To address these challenges, innovative solutions such as the magnetic quick mold change system have been developed.

Magnetic Quick Mold Change System: This cutting-edge system utilizes advanced magnetic circuit technology and pulse discharge technology. By controlling the magnetic circuit distribution electrically, it enables the rapid attachment and detachment of molds, with the clamping and releasing process taking just a few seconds. It ensures strong and consistent magnetic force, eliminating the risk of mold detachment due to power failure or magnetic decay over time.

By streamlining changeover processes and enhancing operational efficiency, these systems empower manufacturers to meet the demands of dynamic markets while maximizing productivity and profitability. For more information, please contact HVR MAG at export@hvrmagnet.com