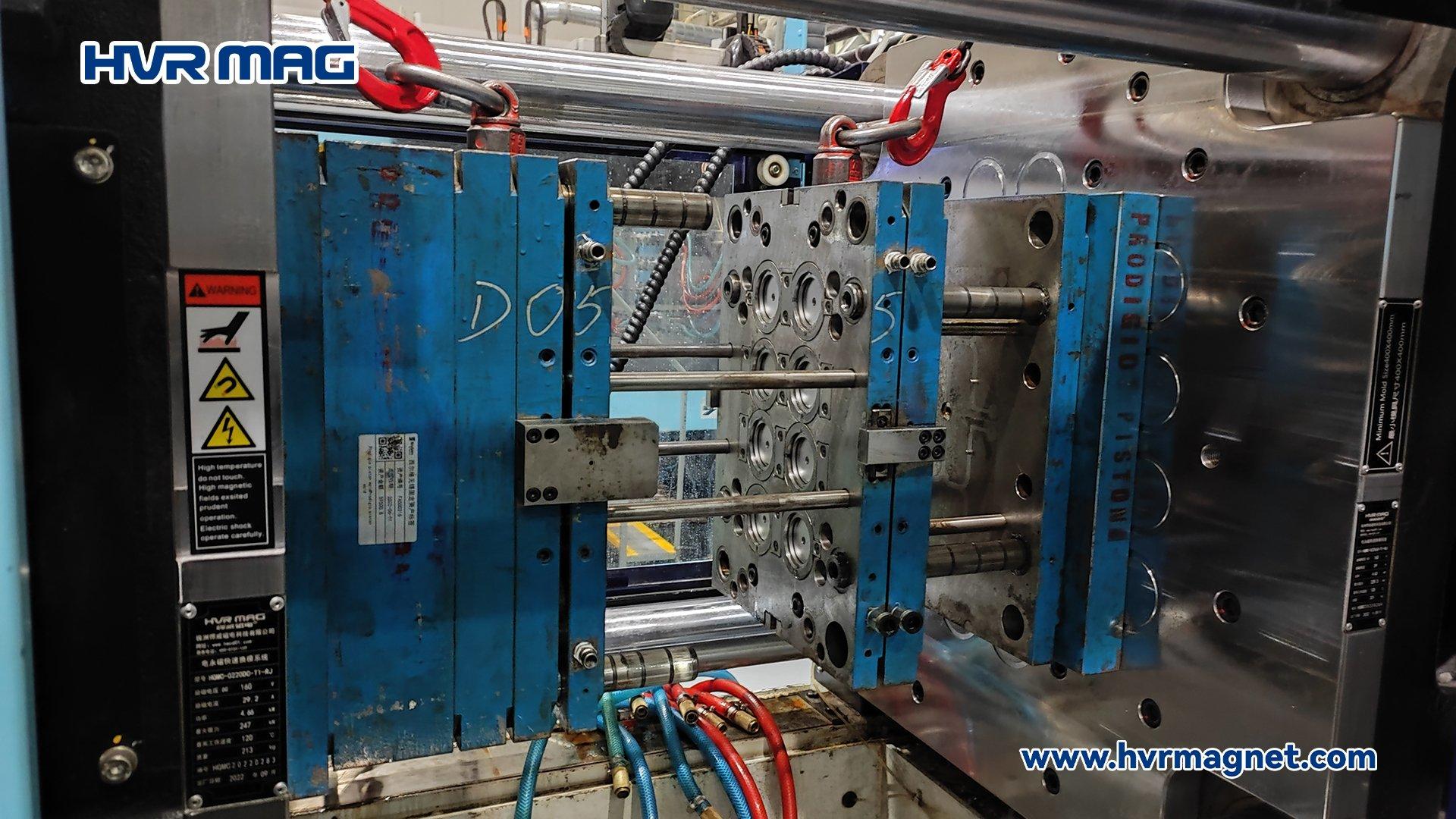

Magnetic platens have become an indispensable part of modern injection molding processes, offering significant advantages over traditional clamping systems in terms of speed and ease of mold exchange. However, as with any mechanical system, issues can arise, leading to the dreaded scenario of a mold dropping. This article explores the conditions under which a magnetic platen may drop a mold. It highlights common causes and offers solutions to prevent such occurrences.

Incorrect Operation and Setup

One of the most frequent reasons for mold drops is improper operation and setup by the mold change operator. This includes:

Incorrect Mold Sizing: When the mold being changed does not fall within the specified range of the magnetic platen, it can lead to instability during the clamping process, potentially resulting in a drop. Ensuring that the mold dimensions are within the magnetic platen’s specified parameters is crucial.

Incorrect Machining Settings: Issues with machine tuning or incorrect settings during mold change can compromise the clamping force, leading to the unexpected release of the mold. Proper training and adherence to machine operating protocols are essential.

Poor Magnetic Platens Quality and Insufficient Testing

The quality of the magnetic platen itself, along with the lack of comprehensive testing, can also lead to mold drops. This includes:

Substandard Platen Material: If the magnetic platen is made from low-quality materials, it may not withstand the rigors of repeated mold changes or the stress of maintaining a tight clamping force over time.

Limited Testing and Monitoring: A magnetic platen with limited or non-existent diagnostic capabilities cannot alert operators to potential issues before they occur. Continuous monitoring systems and regular testing of magnetic performance and clamping capabilities are vital preventive measures.

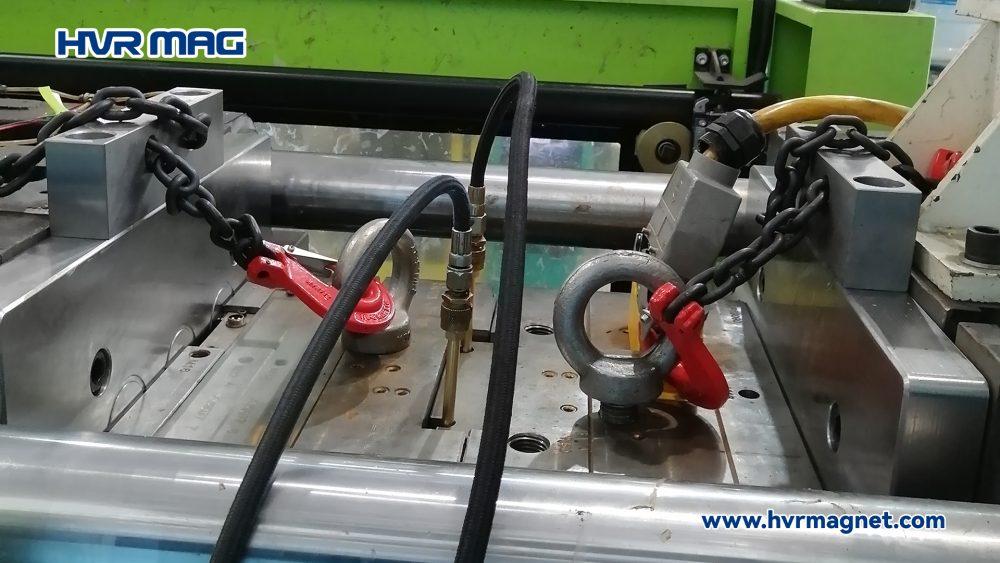

Solutions and Recommendations for Using Magnetic Platens

To prevent mold drops associated with magnetic platens, consider the following solutions:

- Operator Training: Ensure that all mold change operators are properly trained in the correct use of the magnetic platen system, including how to accurately measure and position molds within the specified dimensions.

- Standard Operating Procedures (SOPs): Develop and enforce SOPs for mold change operations, including machine setup and safety protocols.

- Quality Assurance: Use high-quality magnetic platens and perform regular inspections to confirm that the materials and construction are suitable for your application’s demands.

- Comprehensive Testing and Monitoring: Equip your magnetic platens with comprehensive testing capabilities. Monitor them regularly to detect any issues with magnetic field strength or clamping performance. If possible, implement automated systems to alert operators of potential problems.

- Regular Maintenance: Schedule regular maintenance for your magnetic platen system to address any wear or degradation of components that may compromise its performance.

Conclusion

Understand and address the causes of mold drops with magnetic platens. Then, manufacturers can enjoy the benefits of faster production cycles and improved efficiency, without compromising on safety and reliability.