Electro Permanent Steel Plate Lifting Magnets

Electro Permanent Steel Plate Lifting Magnets offer different customized solution to lift and transport steel plates and sheets, from the single steel plate/sheet lifting, to multi steel plates/sheet lifting, which also support release the plates load separately.

Electro Permanent Steel Plate Lifting Magnets also support positioning the plate from horizontal to vertical, moving plates to and from vertical warehouses easily.

Electro Permanent Steel Plate Lifting Magnets Products

Each Electro Permanent Steel Plate Lifting Magnets Type has a safety factor of 3:1, customized for different working condition and needs.

Electro Permanent Steel Plate Lifting Magnets Advantages

Adjustable magnetic force to lifting single steel plate from the pack

Prevents accidental demagnetizing in the air

Abnormal situation reported immediately by an error code

Minimum Safety Factor of 3: 1, measured at an air gap of 0.4 mm

A single operator is able to pick &release the heavy steel safely

Electro Permanent Systems only need electricity in MAG&DEMAG

Steel Plate Lifting Magnets Battery Powered Option

Steel Plate Lifting Magnets available with the option to integrate built-in battery, can be used anywhere, inside or out the factory. The Battery-Powered Steel Plate Lifting Magnets without power cords,reduce the tripping and associated accident.

The battery supports over 500 operations per full charge, meet daily heavy lifting production needs, no electricity is needed during operation,widely used in busy manufacturing facility, a construction site, or a sea port.

Steel Plate Lifting Magnets Telescopic Beam Option

Steel Plate Lifting Magnets featuring a telescopic beam option, to adapt to varying steel plates sizes and weights, ensuring that the lifting magnets can be precisely positioned for optimal grip and stability.

When not in use, the telescopic beam can be retracted to a compact size, saving valuable storage space in the workshop or warehouse.

Steel Plate Lifting Magnets Application

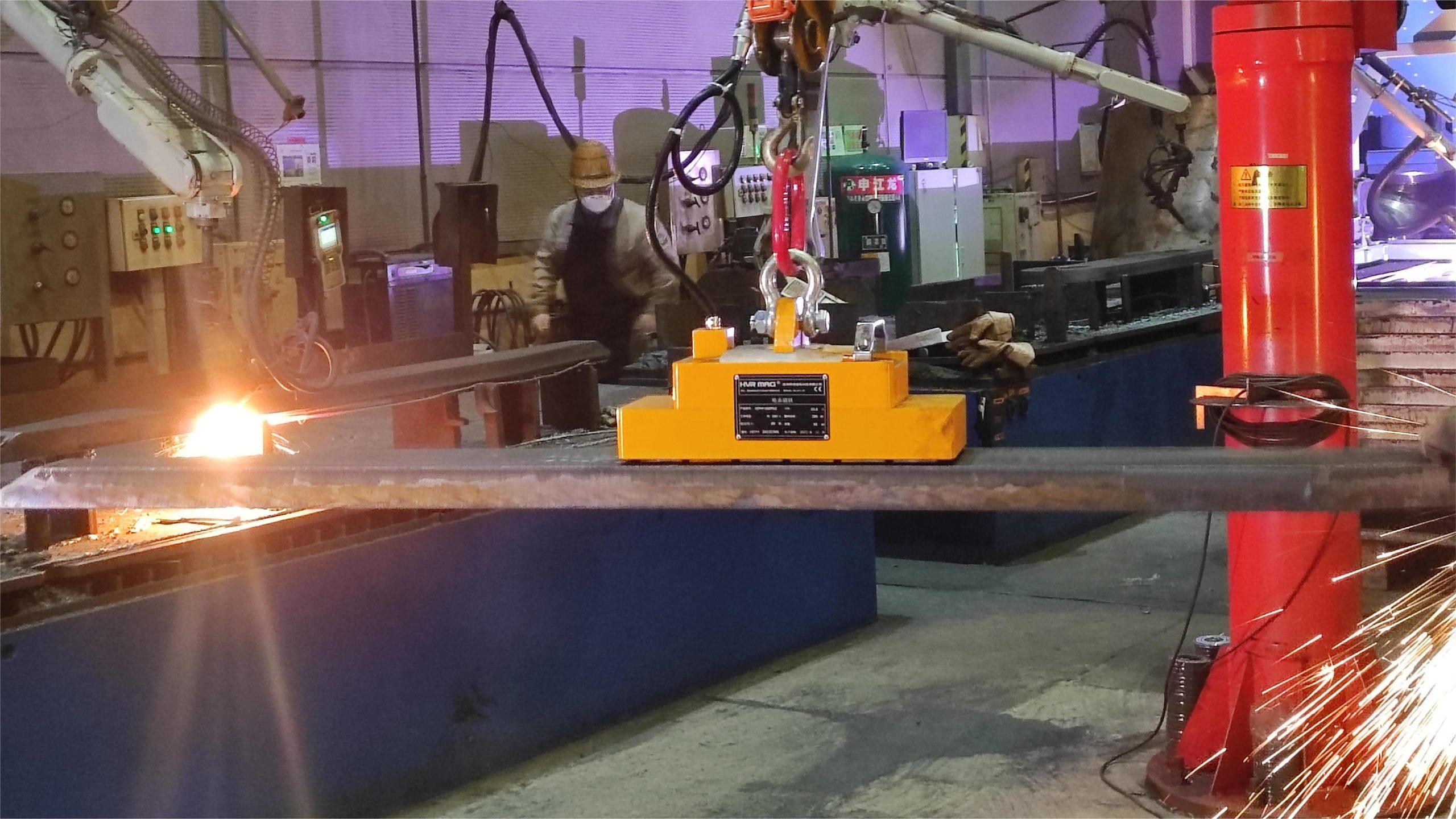

Cutting work is important and normal in steel plate processing. And the intelligence and automation level of steel cutting equipment are constantly improving.

Steel Plate Lifting Magnets for Cutting system is a such equipment, able to load steel plates and swiftly clear cut pieces from cutting tables with a single motion, thereby reducing labor costs and enhancing productivity.

In shipyard and steel structural company, there are many steel plate side lifting operations,using HVR MAG Steel Plate Lifting Magnet, you don’t have to repeatedly adjust the position of the lifting equipment.

During the lifting, the device avoids the potential damage to steel plate edges and corners, leaves no marks on the surface of the steel plate, thus protecting the appearance quality of the steel plate.

Of cause, the special HM3 Series Steel Plate Lifting Magnets for single thin steel sheet, able to lift 2 mm steel plate, guarantee not to stick to the second sheet.

The HM6 Series Steel Plate Lifting Magnets can be designed to lift multiple steel plates, and release a single plate individually.

Single plate release is an optional function, when the Steel Plate Lifting Magnets pick up 2 or more steel plates, it is necessary to put down a steel plate separately at a certain position.

The specific operation is as follows:

When the Steel Plate Lifting Magnets lift multiple steel plates and reach the discharge area, it is necessary to perform a single plate release operation. The Steel Plate Lifting Magnet is lowered to a range of about 100-200 mm from the ground, and the Steel Plate Lifting Magnet is stopped from descending.

At the same time, the front and back, left and right movement is stopped to keep the Steel Plate Lifting Magnet stable and not shake. Please make sure that there is no person or object under the Steel Plate Lifting Magnet (when the single plate discharge function is activated, the bottom steel plate of the spreader will fall. If there are people or objects under the spreader, it will cause a safety accident).

Then press the “lock + single release” button, the yellow indicator light of the Steel Plate Lifting Magnet is always on, and the bottom steel plate falls after a delay. After the steel plate falls, the Steel Plate Lifting Magnet will automatically perform a magnetization operation. After the magnetization action is completed, the green indicator light of the spreader is always on. At this time, the Steel Plate Lifting Magnet can be lifted and moved to the next discharge location for discharge.

Repeat the above operation for the single plate release operation. If there is only one steel plate left on the steel plate lifting magnet, after reaching the discharge location, lower the Steel Plate Lifting Magnet until it is completely on the ground for a demagnetization operation to achieve upload.