In heavy industrial manufacturing, handling large workpieces at high temperatures presents significant challenges. At HVR MAG, we specialize in electro-permanent magnetic solutions designed to operate reliably under demanding conditions. This case highlights the successful application of our magnetic workholding technology for automated handling of high-temperature components at a smart factory in the coal mining machinery industry.

The customer manufactures large connecting rod components for coal mining equipment. After full welding, these workpieces remain at temperatures of up to 200 °C and weigh as much as 3 tons. Previously, the factory relied on traditional lifting methods such as steel wire ropes, hooks, and chains. These methods required multiple operators, involved complex manual positioning, and often caused surface damage or deformation during lifting, especially when handling hot parts.

HVR MAG Solution:

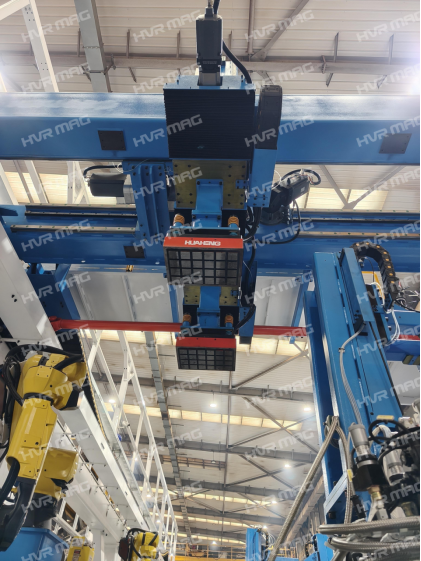

To improve safety, efficiency, and stability, HVR MAG designed a customized high-temperature magnetic workholding solution. The system uses two HEPMP-2000A-GW electro-permanent magnets, specially developed to withstand continuous operation at 200 °C. The magnets are arranged in a 1×2 configuration and installed on a heavy-duty automated gantry system with a total handling capacity of 5 tons. Each magnet provides a rated lifting force of 2 tons, ensuring safe and stable handling of the hot workpieces.

During operation, the magnetic workholding system grips the workpiece directly from the surface using strong magnetic force. This non-contact gripping method eliminates the need for mechanical clamping, reducing the risk of deformation, scratches, or impact damage. Group control allows the system to adapt to different workpiece sizes and specifications while maintaining precise positioning during automated loading and unloading.

After implementation, the customer reported clear improvements. Production efficiency more than doubled, while labor requirements dropped from three to four operators down to one. Workplace safety improved significantly, with a noticeable reduction in lifting-related injuries. The stability of the handling process also helped lower defect rates caused by deformation during lifting.

This application demonstrates how magnetic workholding solutions can perform reliably even in high-temperature environments. By combining heat-resistant electro-permanent magnets with automation, HVR MAG helps manufacturers achieve safer operations, higher efficiency, and more consistent production results in challenging industrial conditions.