Handling cylindrical metal parts such as round tubes, shafts, and solid cylinders often presents unique challenges in automated and semi-automated production lines. Unlike flat steel plates, cylindrical surfaces provide limited contact area for traditional magnetic tools, which can affect gripping stability and positioning accuracy. At HVR MAG, we design electro-permanent magnetic solutions specifically for these scenarios, providing reliable and repeatable performance when lifting or positioning round metal components. Our workholding magnet technology offers a practical alternative to mechanical clamps and complex fixtures in many industrial environments.

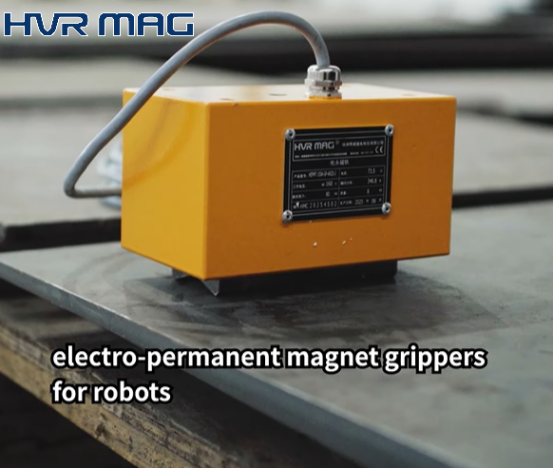

Electro-permanent magnets combine the advantages of permanent magnets and electromagnets. They require electrical power only during magnetization and demagnetization, while maintaining a stable holding force without continuous energy consumption. This feature supports energy-efficient operation and enhances safety during handling. When integrated with robotic arms, gantry systems, or manual hoists, the magnets allow smooth pick-and-place movement and accurate positioning of cylindrical steel parts.

Special design of the magnet:

A key design feature for cylindrical handling lies in the magnetic pole structure. For round workpieces, HVR MAG applies a specially engineered V-shaped pole design. This geometry allows the magnet to better match the curved surface of pipes and shafts. By increasing the effective contact area between the magnet and the workpiece, the system achieves stronger and more balanced magnetic force. The V-shape also improves alignment during lifting, reducing the risk of slipping or rotation during transfer.

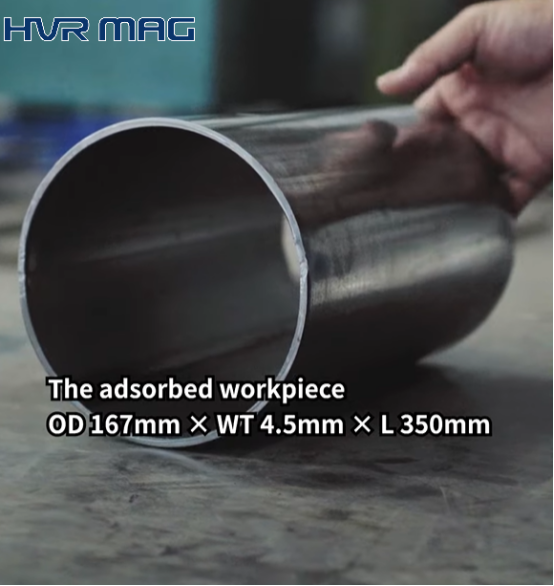

Dimension of the component:

In this demonstration, the handled workpiece is a steel pipe with dimensions OD 167 mm × WT 4.5 mm × L 350 mm. The electro-permanent magnet grips the pipe securely and maintains stable holding throughout the lifting cycle. The optimized pole design ensures even force distribution along the curved surface, enabling smooth and controlled movement without mechanical clamping or surface damage.

Electro-permanent magnetic solutions for cylindrical parts provide flexibility across various industries, including machining, fabrication, assembly, and material transfer. With reduced mechanical complexity and minimal maintenance requirements, they help manufacturers streamline workflows and improve operational consistency. Through continuous development and application experience, HVR MAG delivers magnetic technologies that adapt to real production needs and support efficient, precise handling of cylindrical metal workpieces.