في HVR MAG, we develop magnetic solutions that support reliable and efficient automation. In this project, a customer required a magnetic gripper in robotics to work with a robotic arm for the automated palletising of perforated rectangular metal pipes. The objective was to achieve stable handling, high efficiency, and consistent stacking quality in a fully automated process.

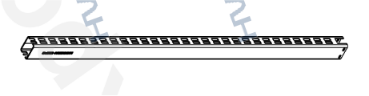

Dimension data:

The workpieces are rectangular metal pipes with perforations and varying dimensions. The pipe length ranges from 800 to 2845 mm, with widths between 40 and 110 mm and a height of 30 mm. Wall thickness is 1.5–3 mm, and the maximum weight of a single pipe is 15 kg. Due to the perforated structure and thin walls, the customer needed a gripping solution that could provide reliable holding force without deforming or damaging the workpieces.

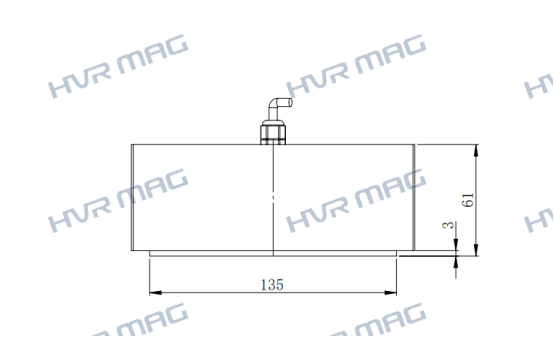

HVR Solution:

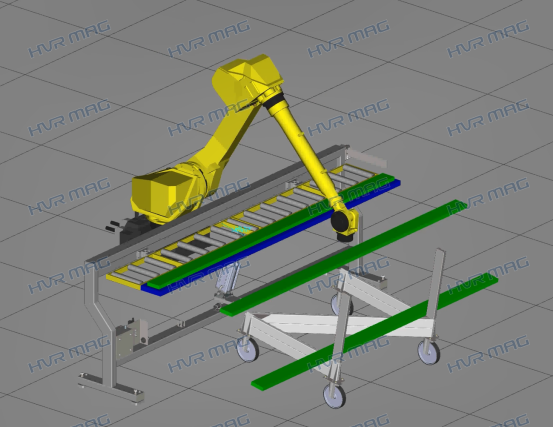

Based on these requirements, HVR MAG designed a robotic magnetic gripper in robotics solution using two HEPMP-1605M electro-permanent magnets working together. Each magnet provides a holding force of 15 kg, allowing the robot to safely lift, transfer, and palletise the pipes. The magnetic gripper is installed directly on the robot end-effector and integrates smoothly with the existing robotic control system.

During operation, the magnetic gripper in robotics enables fast and repeatable pick-and-place cycles. The magnetic gripping method removes the need for mechanical clamps, simplifying the end-of-arm tooling and reducing maintenance. Even with different pipe lengths and perforated surfaces, the system maintains stable gripping and accurate positioning throughout the palletising process.

The electro-permanent magnet design requires power only during magnetization and demagnetization, ensuring secure holding and energy-efficient operation. The automated palletising system improves productivity while maintaining consistent stacking quality and operational stability.

This project shows how a well-designed magnetic gripper in robotics can support automated palletising of lightweight, perforated rectangular metal pipes, offering a practical, stable, and efficient solution for modern robotic automation applications.