DYCM Series Electro Permanent Magnetic Chuck

Electro permanent magnetic chuck can be activated & deactivated within just a few seconds. During the clamping phase, the electric power is excluded, allowing it to obtain the highest level of safety. Apart from energy saving, the magnetic chuck will maintain a cold condition with the related absence of dilations or deformations.

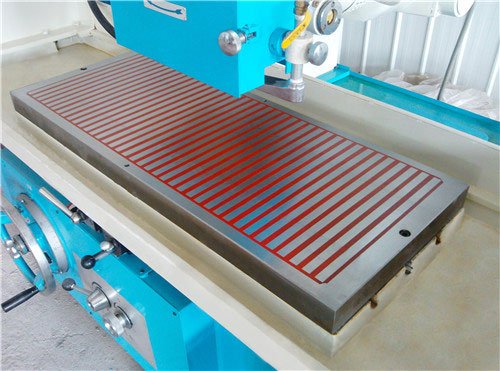

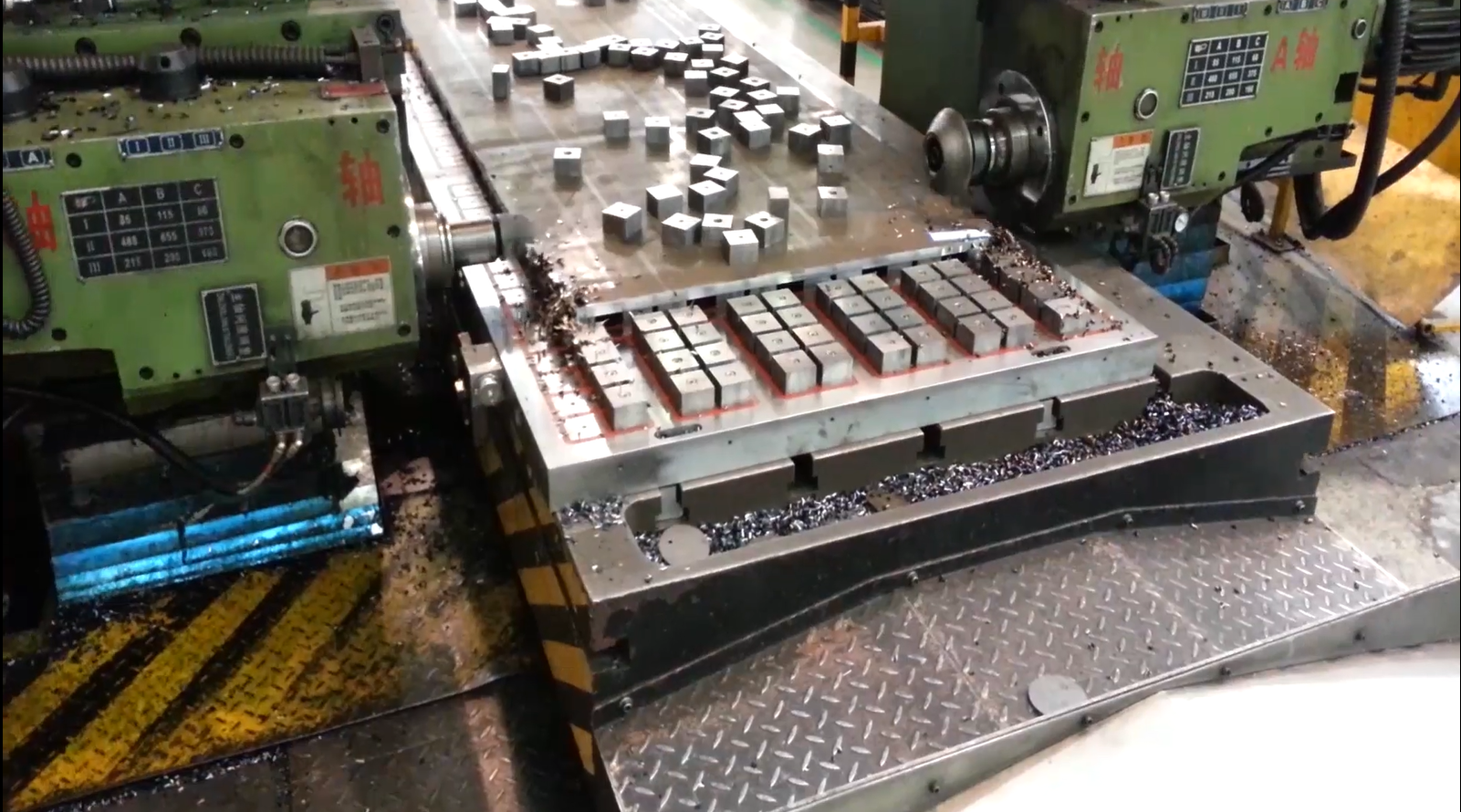

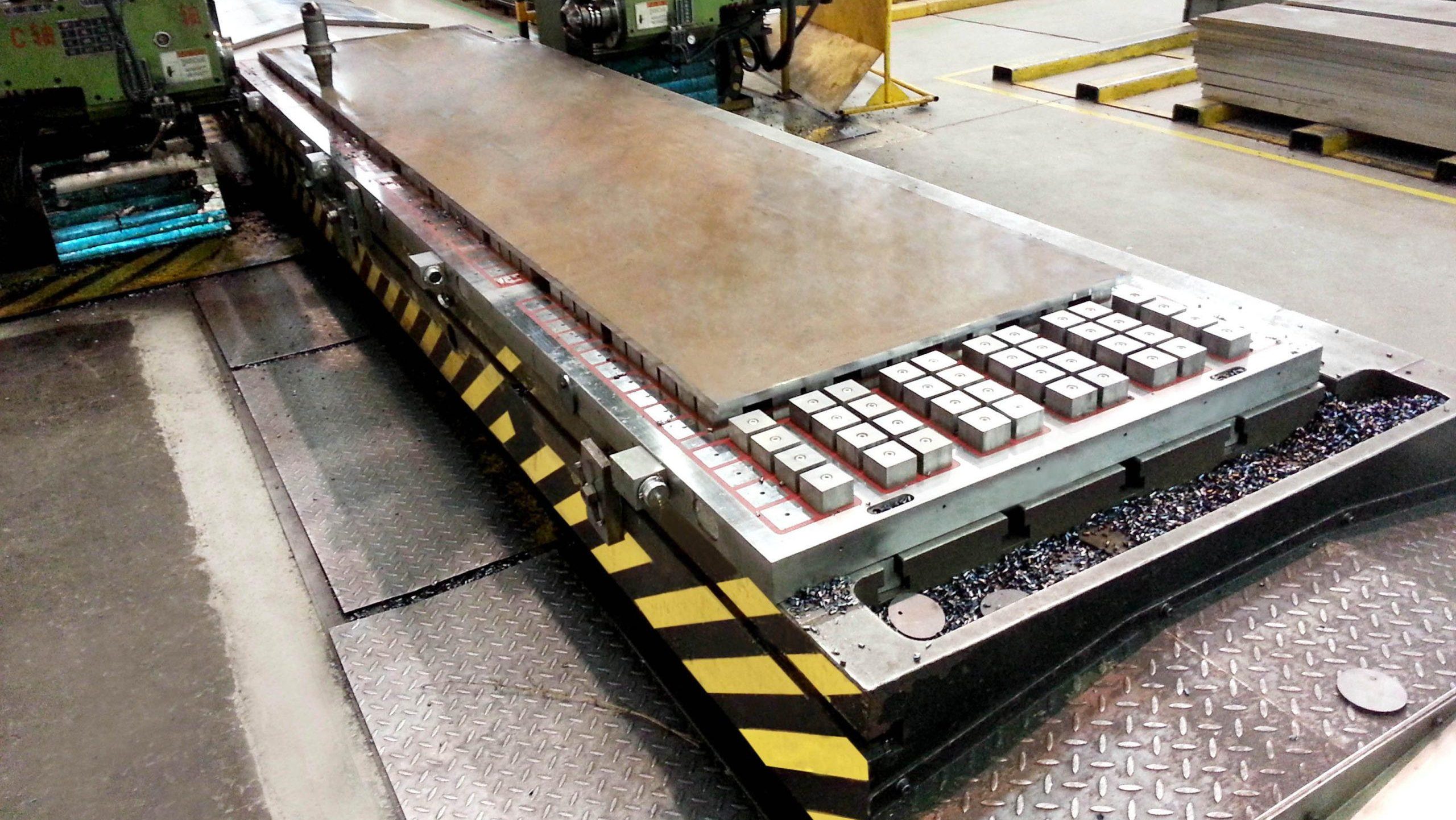

Application of Electro Permanent Magnetic Chuck for Grinding

Grinding Process with Electro Permanent Magnetic Chuck

Grinding Process with Electro Permanent Magnetic Chuck Magnetic chuck for surface grinding and milling on the lathe

Magnetic chuck for surface grinding and milling on the lathe Plane surface grinder machining with magnetic chucks

Plane surface grinder machining with magnetic chucks

Technical Parameters

| Type&Data | Total magnetic force(≤KN) | Overall dimension(mm) | Weight(kg) | |||

| A | B | H | h | |||

| DYCM-3015 | 13.5 | 300 | 150 | 57 | 20 | 20 |

| DYCM-3515 | 15 | 350 | 150 | 57 | 20 | 24 |

| DYCM-4015 | 18 | 400 | 150 | 57 | 20 | 28 |

| DYCM-4515 | 22.5 | 450 | 150 | 57 | 20 | 32 |

| DYCM-4020 | 27 | 400 | 200 | 57 | 20 | 38 |

| DYCM-4520 | 29.25 | 450 | 200 | 57 | 20 | 44 |

| DYCM-4525 | 31.5 | 450 | 250 | 57 | 20 | 50 |

| DYCM-5025 | 33.75 | 500 | 250 | 57 | 20 | 58 |

| DYCM-6025 | 36 | 600 | 250 | 57 | 20 | 68 |

| DYCM-8030 | 69 | 800 | 300 | 57 | 20 | 98 |

| DYCM-10030 | 72 | 1000 | 300 | 57 | 20 | 115 |

| DYCM-10032 | 90 | 1000 | 320 | 57 | 20 | 125 |

| DYCM-8040 | 108 | 800 | 400 | 57 | 20 | 128 |