HVR MAG Lifting Magnet

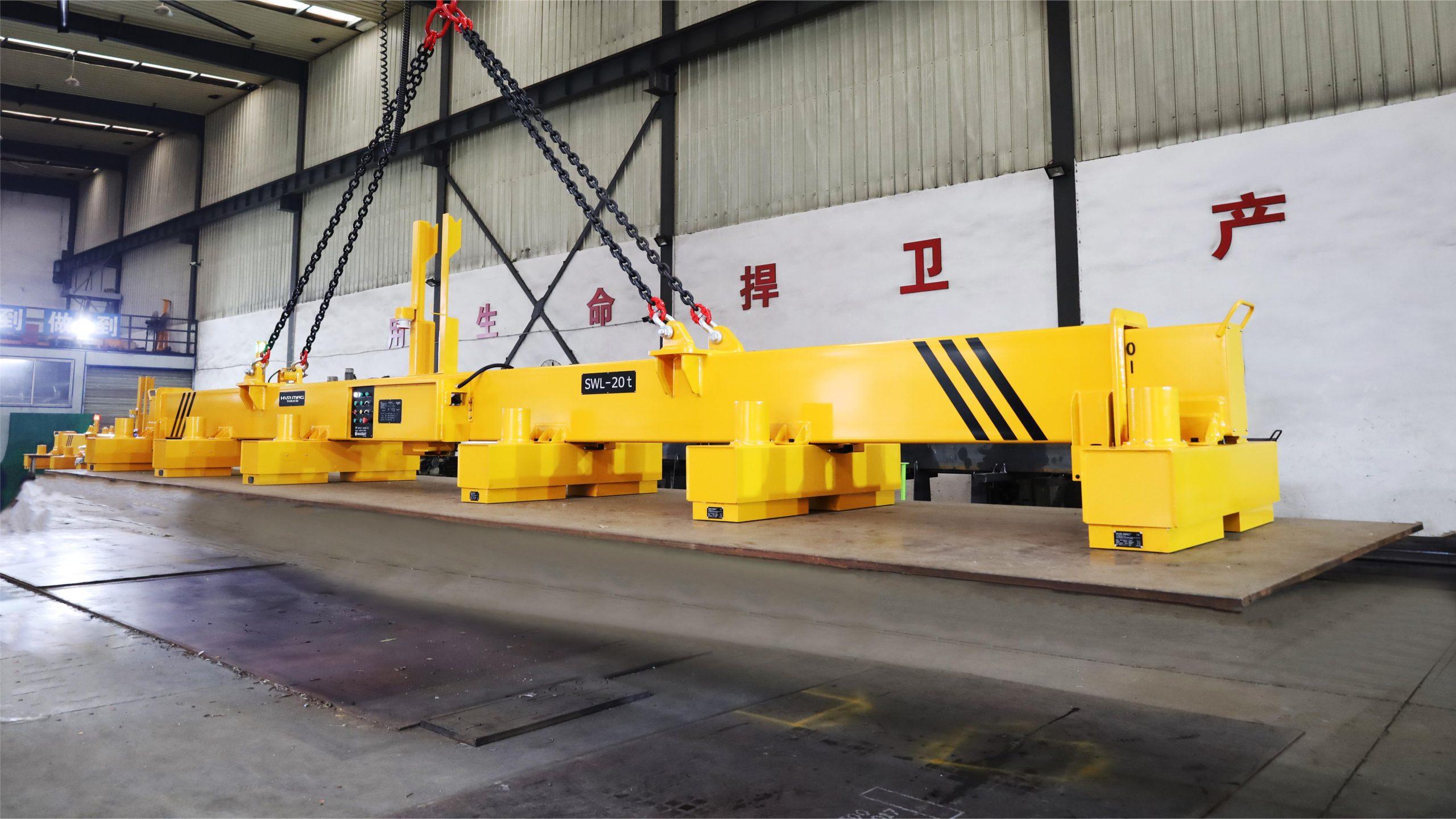

HVR MAG focuses on the design and production of lifting magnet, addressing a wide range of industrial material handling needs. We provide a full range of lifting magnets for handling ferrous materials such as steel plates, coils, strips, profiles, pipes, billets, round bars, and rails.

Additionally, we offer customized lifting magnet solutions specifically designed to fit the unique requirements of our clients.

Lifting Magnet By Material

HVR MAG Lifting Magnet is meticulously categorized by the type of ferrous materials they handle, ensuring the perfect fit for any lifting challenge in the steel industry.

HVR MAG Lifting Magnet By Function

Designed for specific needs, HVR MAG Lifting Magnet offers a range of functionalities such as battery supply for portability, telescopic beams for extended reach, cutting system integration for precision, and forklift compatibility for versatile material handling

Lifting Magnet Feature

Efficient, Precise, and Safe handling of Steel Material With The Electro-Permanent Lifting Magnet

Only uses electricity in MAG & DEMAG phase, saving energy up to 95%

Magnetization/demagnetization with in 2 seconds

Unique structure consisting of dual magnetic source

Magnetic force can remain even in a sudden power failure

No moving parts inside nearly no maintenance cost

Uniformly distributed magnetic force

What is HVR MAG Lifting Magnet

HVR MAG lifting magnet uses the electro permanent magnet technology, which is the most efficient solution to securely grip, transport, and release heavy ferrous loads, can be customized to meet the unique requirements of different clients, including size, shape, and weight capacity, ensuring the perfect fit for specific applications, are widely used in steel structure, shipyard, warehouses, steel mills.

Electro Permanent Lifting Magnet Highlight

- Unique Electro permanent magnetictechnique using double magnet systems.

- Only need electricity during switching magnet ON and OFF, saving 95% energy.

- Power-off holding to ensure the load remains in the event of a sudden power failure.

- Designed for specific weight capacities and material handling needs, perfect fit for various applications

- Durability and Low Maintenance

HVR MAG Lifting Magnet Working Principal

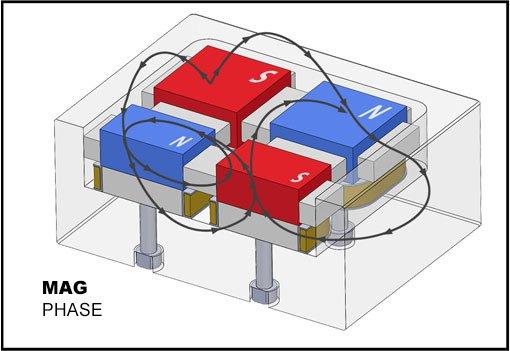

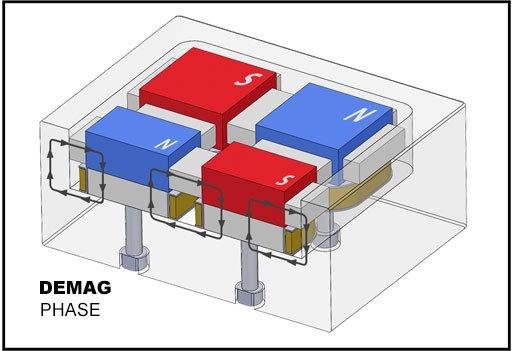

HVR MAG lifting magnet choose the electro-permanent magnet, which use an upgraded hybrid of two different types of magnetic materials: a magnetically hard material, like Nd-Fe-B, and a semi-hard material, such as Alnico. Mag and Demag through instantaneous electric current, allowing magnets to maintain their magnetic or non-magnetic state without the need for electrical power, thus preventing accidents in case of power failure. The pulling force can reach up to 16KG per square centimeter.

These materials are enclosed at both ends with a magnetically soft material, usually iron, and are surrounded by a coil. When a current pulse of a certain polarity passes through the coil, it aligns the materials and enhances the external magnetic flux.

Conversely, when a current pulse of the opposite polarity is applied, it reverses the magnetization of the semi-hard material while the hard material remains unchanged. This process redirects some or all of the magnetic flux to circulate within the device, effectively decreasing the external magnetic flux. The result is a precise and efficient way to control magnetic fields for various applications.

China Electro Permanent Lifting Magnet Manufacturer Advantage

HVR MAG Lifting Magnet are widely used in Steel Mills, Automotive, Offshore, Shipbuilding,Machinery& Equipment Manufacturing and Logistics industry.

With a experienced R&D team and over 40 patents, all of HVR MAG Electro Permanent Lifting Magnet are customized according to the customer local standard and reality usage necessary.

Not only electro permanent lifting magnet customization, but also provide Anchor Points, Paints, Suspension Brackets, Waterproof, Chain Suspension, and High Temperature Resistance design options.

HVR MAG own 30,000㎡+ modern factory, compliance the ISO 9001 and ISO 14001, equipped advanced production equipment to assurance capacity and quality control , quality test before shipping, aim to delivery the high quality electro permanent lifting magnet to global customers on time.

At the same time, afford the responsibility of environment protection during the production.

Lifting Magnet Cooperation Company

Contact Us For Lifting Magnet Solution

You’ll receive exclusive access to new lifting magnet releases, technical insights, and industry achievements.

Don’t miss out on this opportunity to stay informed and ahead of the curve in the world of lifting magnet technology.

Loads objects such as steel plates need to provide length, width, thickness and material parameters; Such as steel pipe need to provide the diameter, wall thickness, length and weight parameters. Other tooling parts also need to provide relevant parameters, then we will provide you the customized lifting magnet solution.

It is better to provide drawings or photos if it is particularly complicated.

Whether indoor or outdoor lifting, normal temperature, lifting height and maximum lifting weight, driving type, etc.

It not suitable for stainless steel, only suitable for materials with good magnetic conductivity.

HVR MAG are professional manufacturer for researching and production of electro-permanent lifting magnet, not include electric hoists, about beams, we can help you design and make, or let you make your own, so as to reduce the cost of products and transportation costs.

The magnetic force of HVR MAG lifting magnet is generated by permanent magnet materials, power failure will not affect the lifting process, and there are many anti-misoperation function for the lifting magnet.