HMC2 Series

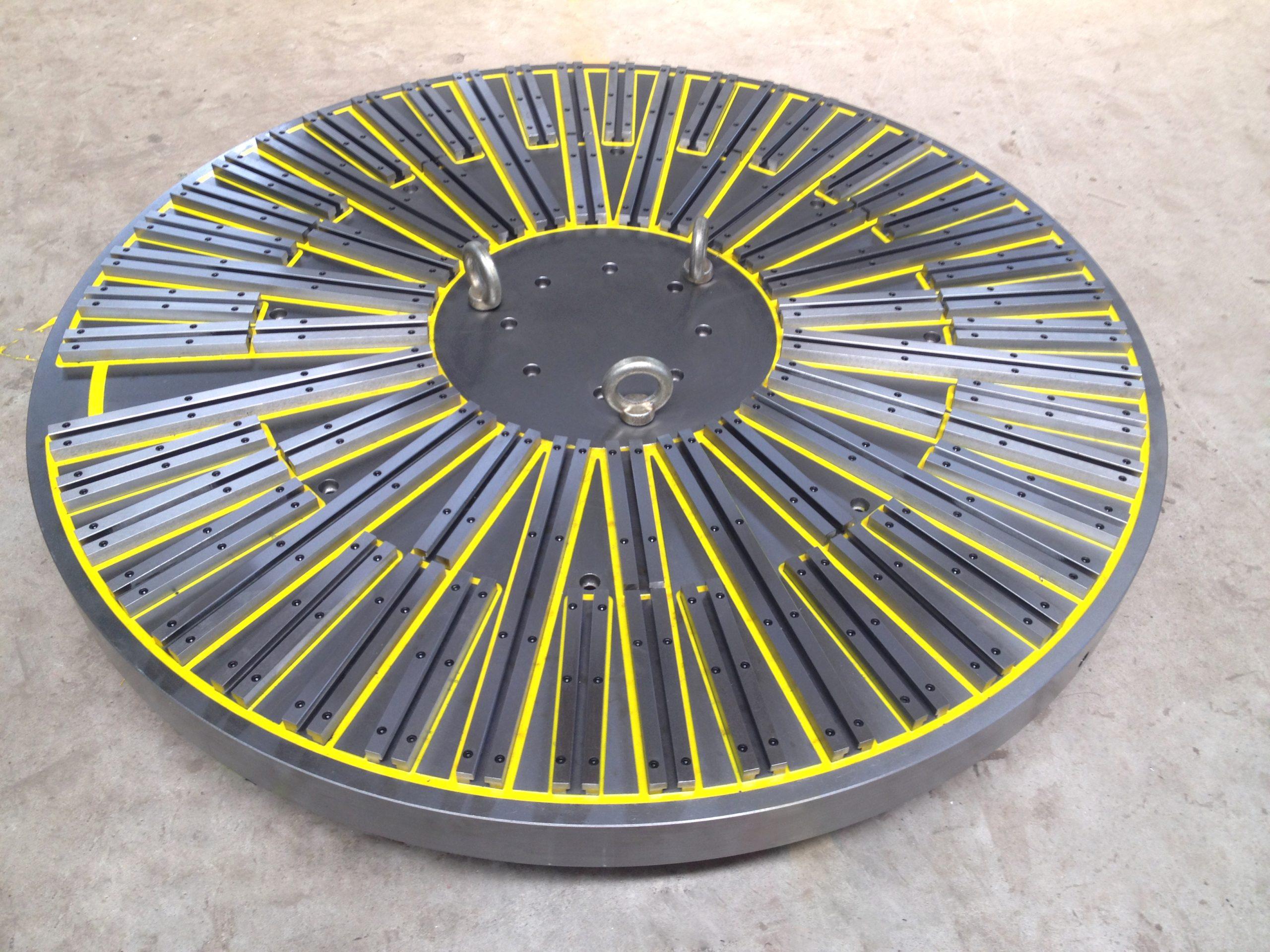

Electro Permanent Magnetic Chuck for Lathe provide a solution by clamping the workpiece from its base surface. This setup allows uninterrupted tool paths and enables complete machining in a single setup.

- High Efficiency

- 95% Energy Saving

- Extremely Safe

- Maintenance Free

- HMC2 Data Sheet

| Type&Data | Magnetic pole number | Total magnetic force(≤KN) | Overall dimension(mm) | Weight(kg) | ||

| D | D | H | ||||

| HMC2-500 | 12 | 41 | 500 | 60 | 70 | 95 |

| HMC2-600 | 12 | 41 | 600 | 60 | 70 | 135 |

| HMC2-800 | 16 | 55 | 800 | 150 | 80 | 290 |

| HMC2-1000 | 16 | 55 | 1010 | 200 | 80 | 460 |

| HMC2-1300 | 24 | 82 | 1300 | 300 | 90 | 680 |

| HMC2-1500 | 24 | 82 | 1520 | 500 | 100 | 1240 |

| HMC2-1600 | 40 | 137 | 1620 | 800 | 125 | 1560 |

| HMC2-1800 | 40 | 137 | 1820 | 800 | 125 | 2050 |

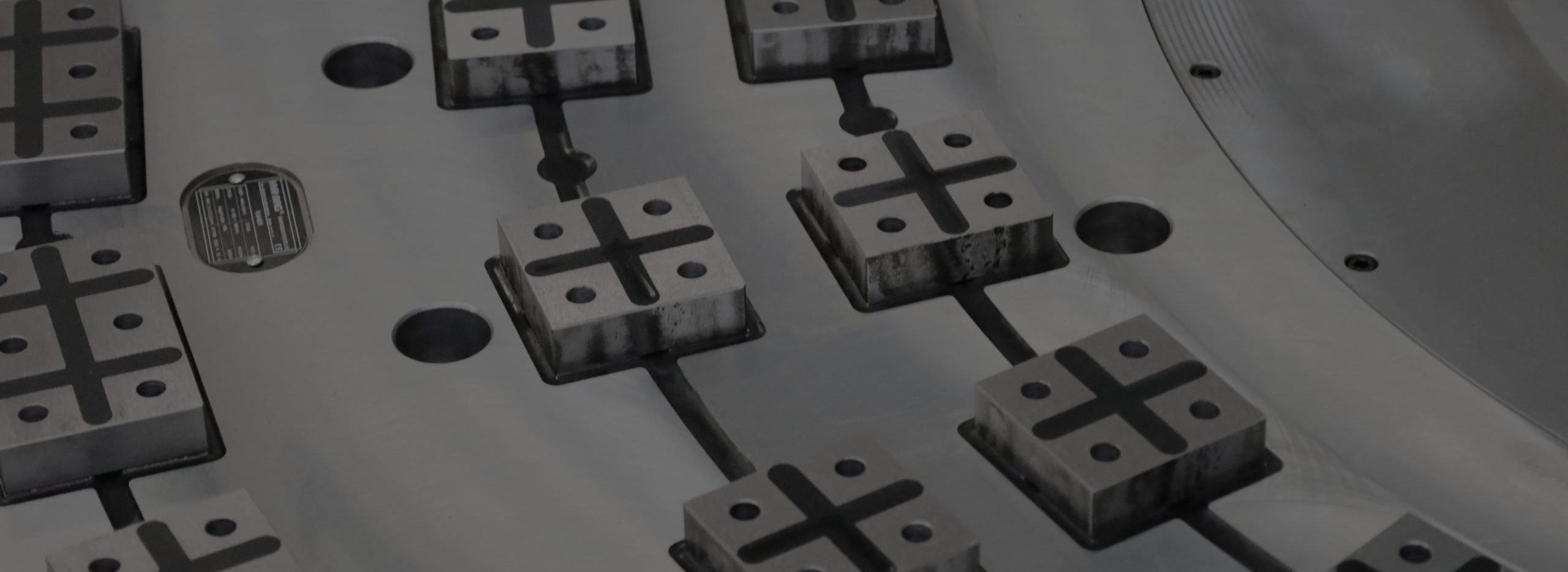

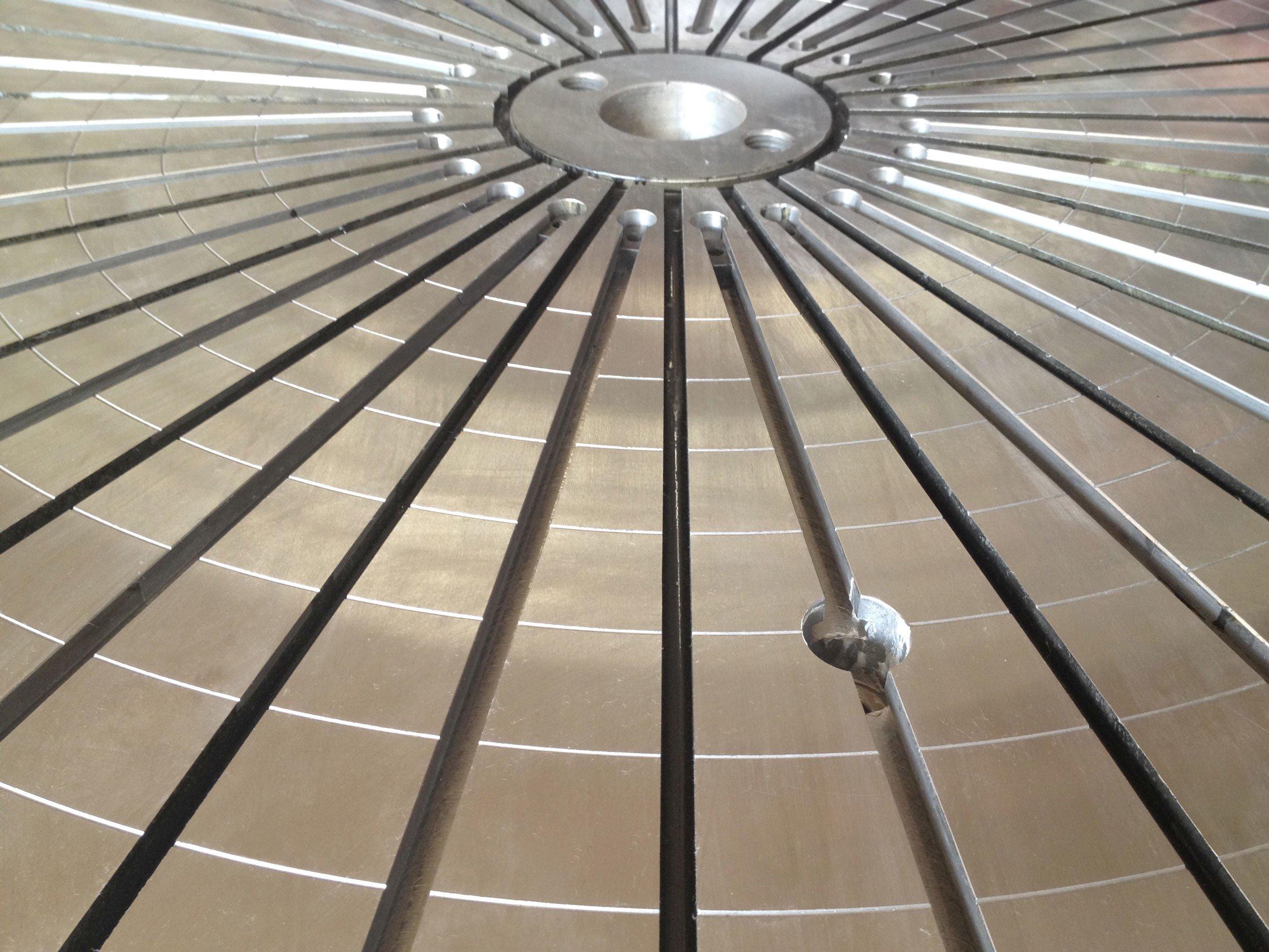

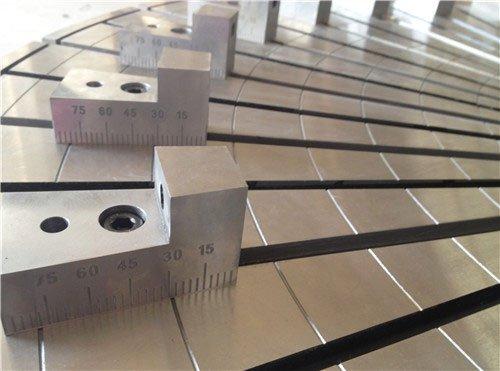

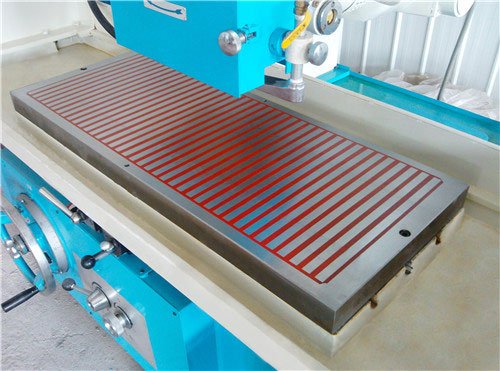

Construction & Features

- Dual magnetic circuit design.

- Unique variable cross-section magnetic polestructural design makes the magnetic fieldsuperimposed.

- 5-sides machining,drilling, tapping, grooving and forming can be done in one cycle.

- All steel surface magnetic chuck is waterproof.

- 2 seconds to activate or deactivate magnetism.

- Circular grinding, roughing, turning of circularor cylindrical parts.

- The specific version of the chuck depends onthe customer’s desired application.

- Suitable for vertical lathe machine, cnc 5-aixs precision indexing device, cnc 5-aixs comprehensive cutting machine tools.