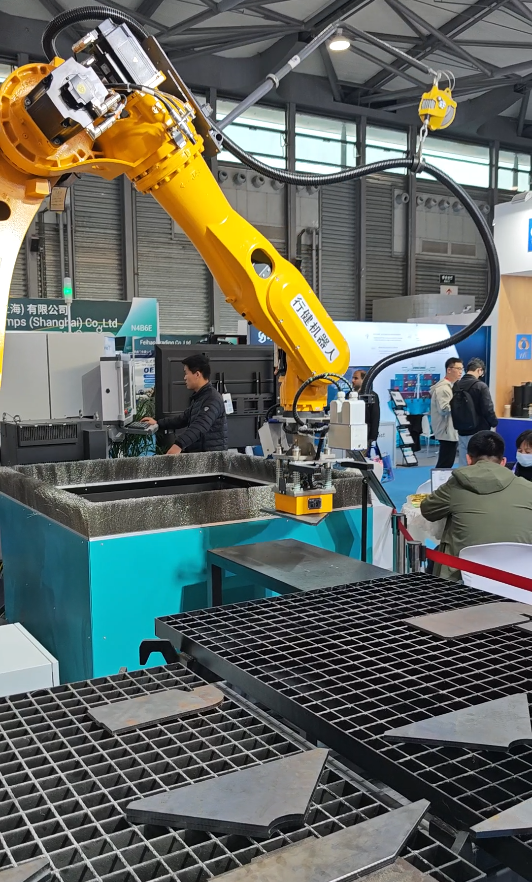

In many workshops, picking up laser-cut steel parts by hand can be slow and tiring. A practical solution we’ve seen involves fitting a magnetic gripper to the end of a robot arm. This setup helps to automatically lift and move parts after cutting.

Integration with Vision Guidance Systems

When combined with robotic vision systems, the magnetic gripper enables precise component localization and retrieval. The vision system identifies cut parts’ positions and orientations, then communicates coordinates to the robotic controller. The gripper subsequently positions itself accurately over each component, engaging only when proper alignment is achieved. This coordinated approach reduces positioning errors and minimizes part damage during handling.

What This Means for the Workshop

This approach helps keep the work area organized and allows the cutting machine to run more continuously. Workers spend less time sorting parts by hand and can focus on other tasks. The magnetic gripper is simple, with no moving parts, so it requires little maintenance and works consistently shift after shift.

Setting It Up

To make this work well, the magnet needs to be the right strength for the parts being lifted. The camera system should be adjusted to recognize parts clearly under the workshop lighting. Good communication between the camera, robot, and gripper makes the whole process smooth and efficient.

This is one example of how magnetic grippers, when combined with basic automation, can help workshops work smarter—reducing manual effort while keeping things running smoothly.