Electro Permanent Magnetic Telescopic Lifting Beam

- Telescopic System:Powered by electricity for steel material with different length

- Thickness Lifting: Starting from a minimum thickness of 5mm

- Landing Detection: prevent unintentional demagnetization while the steel sheet is airborne.

- Remote Control: Digital push buttons and radio remote control

- High Safety: 3:1 safety factor.

What is Electro Permanent Magnetic Telescopic Lifting Beam

Electro Permanent Magnetic Telescopic Lifting Beam Integrate telescoping beam allows for adjustable reach, to handle variable-length steel plates, steel tubes, and profiles in tight spaces. Equipped with the eletrically driven telescopic arms, just adjust the arm remotely to satisfay the reality application needs, there is no necessary to change the lifting magnet modules.

Magnetic Telescopic Lifting Beam is a ideal choice for efficient and safe material handling in industries such as steel processing, construction, and manufacturing.

Magnetic Telescopic Lifting Beam Feature

Provides the ability to handle materials in hard-to-reach areas, enhancing flexibility in material handling

Quickly adjust to different lifting requirements, accelerating material handling processes.

Reduce the risk of workplace injuries by minimizing the need for manual handling of heavy materials

Reduce operational costs by minimizing material damage and downtime associated with manual handling

By adjusting to the lengths, enable optimize storage space, allowing for more efficient use of warehouse racks and stacks

Abnormal situation reported immediately by an error code

Magnetic Telescopic Lifting Beam Battery Powered Option

HVR MAG offer customized Magnetic Telescopic Lifting Beam to meet the high steel application requirements.

For steel mills, port, outdoor shipbuilding and offshore, Magnetic Telescopic Lifting Beam supply versatile battery-powered design to handle heavy materials without external power.

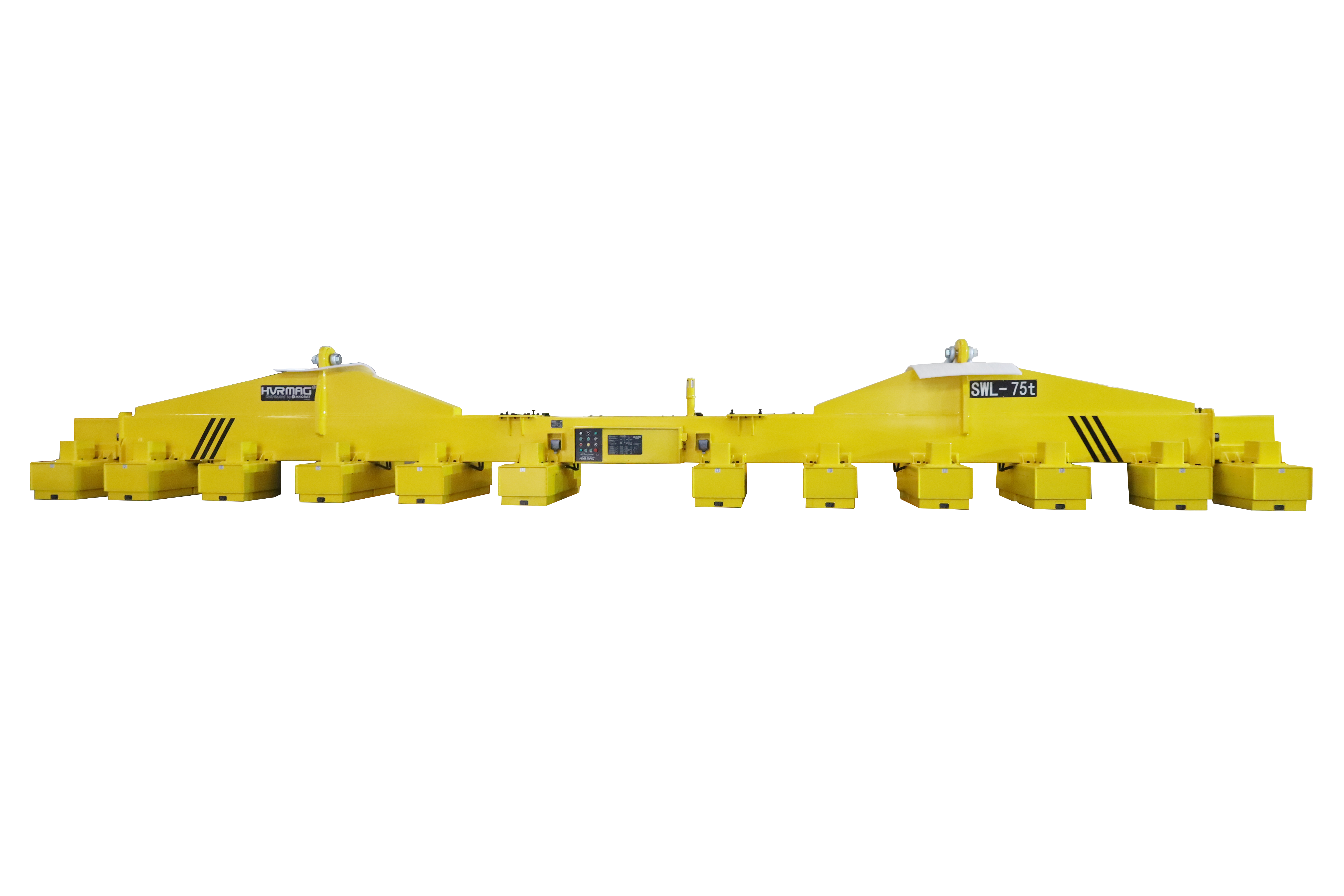

Magnetic Telescopic Lifting Beam Working Module Option

The Magnetic Telescopic Lifting Beam is used to transport ferrous loads of different sizes.

When handling some smaller parts, like the short plats, there are some magnetic modules will not be used. The Magnetic Telescopic Lifting Beam can turn off the unnecessary magnetic modules, not only versatility application, but also save the energy.

Magnetic Telescopic Lifting Beam Application

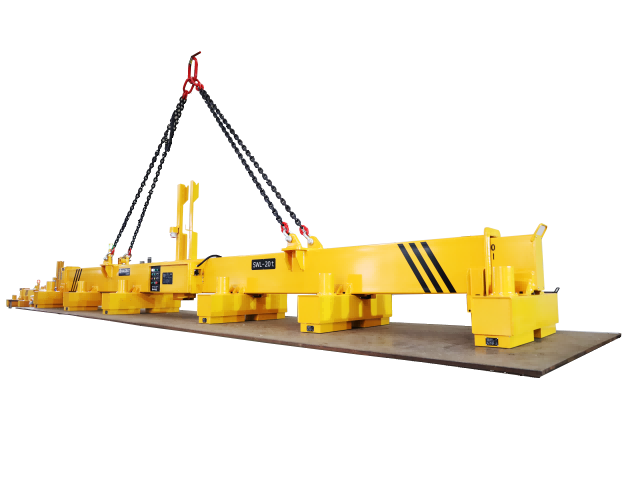

Magnetic Telescopic Lifting Beam specifically designed to handle steel plates of varying dimensions efficiently. They extend and retract to accommodate different lengths, enabling precise placement of materials in high-density storage racks without manual handling.

This operation reduces labor costs, minimizes the risk of damage to both goods and personnel, and streamlines inventory management, making them an essential tool for modern, efficient warehouse operations.

Magnetic Telescopic Lifting Beam also is useful to load steel plates of different lengths directly onto cutting tables. Allow for the telescoping of the beam to adjust to the length of the plate, providing a quick and safe method to position materials for cutting without physical contact.

This not only speeds up the loading process but also prevents damage to the plate edges and surface, ensuring high precision in cutting operations and reducing the risk of accidents in the workplace.

Magnetic Telescopic Lifting Beam Data Sheet

Art No. | Series Code | Length (mm/in) | Width (mm/in) | Thickness (mm/in) | Dead Weight (kg/Lbs) | Capacity (kg/Lbs) | ||

| Min. | Max. | Min. | Max. | Min. | ||||

HM2-12-050 | HM2-050A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2350/5170 | 5000/11000 |

HM2-12-080 | HM2-080A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2500/5500 | 8000/17600 |

HM2-12-090 | HM2-090A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2650/5830 | 9000/19800 |

| HM2-12-120 | HM2-120A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2800/6160 | 12000/26400 |

HM2-12-150 | HM2-150A0204-1 | 3000/118 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 2950/6490 | 15000/33000 |

HM2-12-200 | HM2-200A0206-1 | 3800/149.6 | 12000/472 | 500/20 | 3500/137.8 | 8/0.3 | 3350/7370 | 20000/44000 |

| HM2-12-240 | HM2-240A0206-1 | 3800/149.6 | 12000/472 | 500/20 | 3500/137.8 | 5/0.2 | 3550/7810 | 24000/52800 |

| HM2-16-090 | HM2-090A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3300/7260 | 9000/19800 |

HM2-16-120 | HM2-120A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3400/7480 | 12000/26400 |

HM2-16-160 | HM2-160A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3600/7920 | 16000/35200 |

HM2-16-200 | HM2-200A0206-1 | 3100/122 | 16000/630 | 500/20 | 3500/137.8 | 5/0.2 | 3800/8360 | 20000/44000 |

| HM2-16-240 | HM2-240A0206-1 | 3100/122 | 16000/630 | 250/9.8 | 500/20 | 5/0.2 | 4000/8800 | 24000/52800 |

HVR MAG Magnetic Telescopic Lifting Beam provide manual telescoping beams, electronic motorized telescoping beams, pneumatic telescopic beam, rotating beams, and more to adapt to different customers’ production scenarios. Each beam is customized to fit your exact needs.

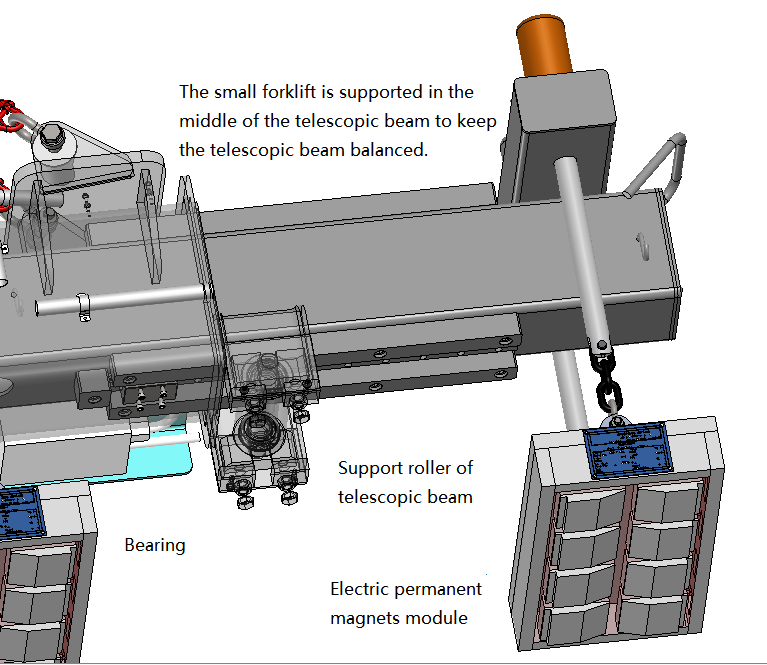

- Manually crank the Magnetic Telescopic Lifting Beam to extend it to the outermost end.

- Remove the electro permanent magnet on the magnetic telescopic lifting beam.

- Support the telescopic beam with a small forklift or other tools.

- Remove the supporting roller of the telescopic beam.

- Remove the screws that fix the slider.

- Use a small forklift to lift the magnetic telescopic lifting beam a little bit, and then take out the slider along the guide rail.