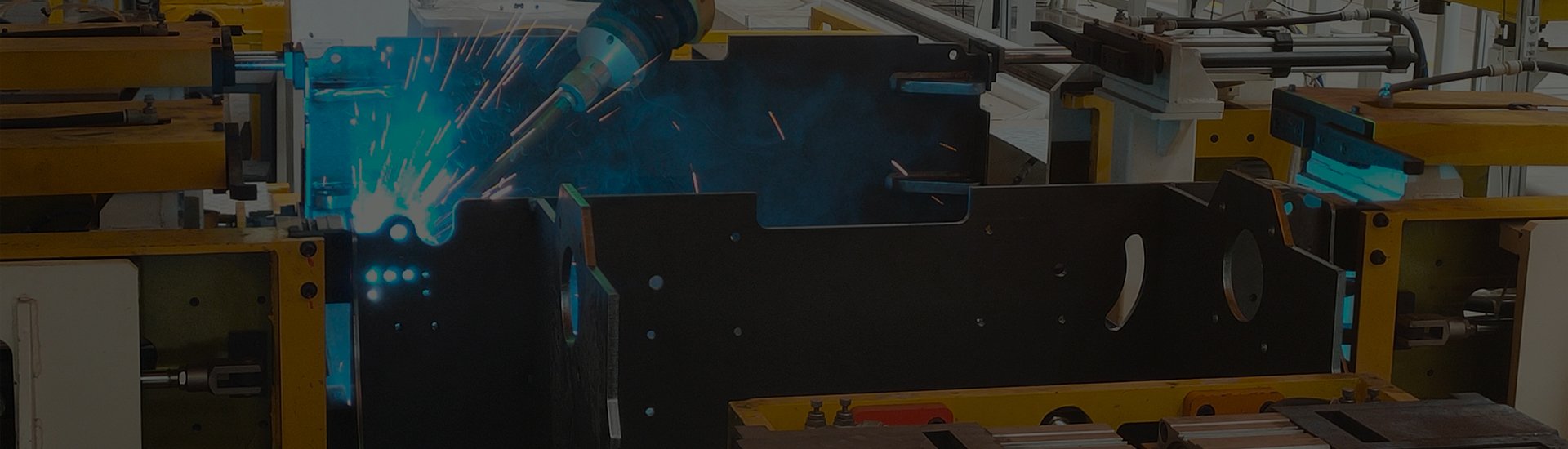

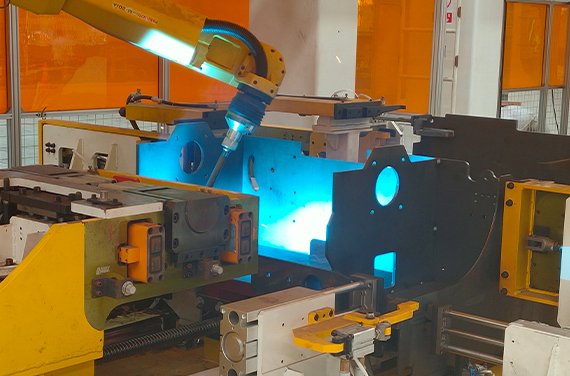

Ferramental de fixação para linha de automação de soldagem

O ferramental de fixação é uma ferramenta e um equipamento usado no processo de soldagem, cuja principal função é garantir que a peça de trabalho permaneça fixa e estável durante o processo de soldagem.

- As ferramentas de fixação podem garantir a precisão e a consistência da soldagem da peça de trabalho.

- Melhorando significativamente a eficiência da soldagem.

- Pode acelerar o processo de preparação e operação da soldagem.

- Suporta o uso repetido em operações de produção em larga escala e de soldagem em lote.

- Os ímãs não alteram seu estado magnético quando há falta de energia.

- A unidade de controle pode ser integrada ao sistema PLC do robô.

- Para placas grossas

- Para placas finas

- Para tubos e barras redondas

- Magneto de formato redondo

| Modelo | Força nominal de elevação (espessura > 16 mm) | Espessura aplicável | L | W | H |

| HEPMP-1510P50 | 160 kg | ≥6mm | 150 mm | 100 mm | 72 mm |

| HEPMP-320P50 | 320 kg | ≥6mm | 180 mm | 180 mm | 72 mm |

| HEPMP-500P50 | 500 kg | ≥6mm | 250 mm | 180 mm | 72 mm |

| HEPMP-640P50 | 640KG | ≥6mm | 320 mm | 180 mm | 72 mm |

| HEPMP-720P50 | 720 kg | ≥6mm | 250 mm | 250 mm | 72 mm |

| HEPMP-2012P70 | 320 kg | ≥8mm | 190 mm | 110 mm | 72 mm |

| HEPMP-2020P70 | 640 kg | ≥8mm | 200 mm | 200 mm | 72 mm |

| Modelo | Força nominal de elevação (espessura > 10 mm) | Espessura aplicável | L | W | H |

| HEPMP-30P30B | 30 kg | 2-12 mm | 100 mm | 54 mm | 58 mm |

| HEPMP-60P30B | 60 kg | 2-12 mm | 100 mm | 100 mm | 58 mm |

| HEPMP-100P30B | 100 kg | 2-12 mm | 140 mm | 100 mm | 58 mm |

| HEPMP-200P30B | 200 kg | 2-12 mm | 260 mm | 100 mm | 58 mm |

| HEPMP-300P30 | 300KG | 2-12 mm | 260 mm | 110 mm | 58 mm |

| HEPMP-60P30 | 60 kg | 3-12 mm | 110 mm | 60 mm | 58 mm |

| HEPMP-1406P30 | 90 kg | 3-12 mm | 140 mm | 60 mm | 58 mm |

| HEPMP-1817P30 | 300 kg | 3-12 mm | 180 mm | 170 mm | 58 mm |

| HEPMP-1906P30 | 120 kg | 2-12 mm | 190 mm | 60 mm | 58 mm |

| HEPMP-120P30 | 120KG | 2-12 mm | 190 mm | 60 mm | 60 mm |

| HEPMP-90P30 | 90KG | 2-12 mm | 150 mm | 60 mm | 60 mm |

| Modelo | Força nominal de elevação (espessura > 12 mm) | Espessura aplicável | L | W | H |

| HEPMSP-60P45×24 | 60 kg | ≥3mm | 145 mm | 90 mm | 81 mm |

| HEPMSP-100P45×24 | 100 kg | ≥3mm | 200 mm | 120 mm | 81 mm |

| HEPMP-2811S | 120KG | ≥3mm | 280 mm | 110 mm | 80 mm |

| HEPMSP-200P45×24 | 200 kg | ≥3mm | 370 mm | 105 mm | 81 mm |

| HEPMSP-300P45×24 | 300 kg | ≥3mm | 435 mm | 105 mm | 81 mm |

| Modelo | Força nominal de elevação | Espessura aplicável | Diâmetro | H | Peso |

| HEPM1-25 | 3KG | ≥2mm | 25 mm | 35 mm | 120g |

| HEPM1-40 | 20KG | ≥2mm | 40 mm | 48 mm | 420g |

| HEPM1-50 | 30KG | ≥10mm | 49 mm | 45 mm | 650g |

| HEPM1-60 | 50KG | ≥10mm | 60 mm | 50 mm | 1 kg |

| HEPM1-75 | 90KG | ≥12mm | 78 mm | 48 mm | 1,5 kg |

| HEPM1-100 | 150KG | ≥14mm | 100 mm | 55 mm | 3,5 kg |

Aplicação de soldagem automotiva

A tecnologia de soldagem automatizada desempenha um papel fundamental no setor automotivo, por exemplo, a soldagem de componentes como estruturas de carros, portas e tetos. Isso não só melhora muito a velocidade de soldagem, mas também garante a qualidade da soldagem e a resistência estrutural da carroceria do veículo, e pode se adaptar à produção de vários modelos de veículos.

Aplicação de placas para soldagem

O ferramental de fixação no sistema de soldagem automatizado pode ser ajustado de acordo com diferentes espessuras de chapas de aço, tipos e processos de soldagem para atender a diversas necessidades de produção.

Aplicação de soldagem de componentes

Muitos componentes têm formas complexas e requisitos de alta precisão, e a soldagem automatizada pode garantir a precisão e a estabilidade da qualidade da soldagem, produzindo assim componentes de alta qualidade.

Fabricante de ferramentas de fixação personalizadas de uma só vez na China

- Forneceremos soluções personalizadas

- Certificação de qualificação completa, exportada para todo o mundo

- Resposta rápida, serviços de pré-venda e pós-venda garantidos

ABB、 Dez grandes marcas, incluindo Fanuc e Estun, bem como Sany Vision Bit, Sylt, Shenyang Xinsong, Huaheng Robotics, Foxconn (eletrônicos), BYD (eletrônicos, automotivos)

Claro, temos nossa própria equipe de P&D e design que pode personalizar produtos que atendam às suas necessidades com base nas condições de trabalho e nos requisitos fornecidos por você.

Todos os produtos da nossa empresa são desenvolvidos de forma independente e contam com o apoio de uma equipe de especialistas técnicos alemães. Temos direitos de propriedade intelectual independentes (seis patentes de invenção, trinta patentes de modelos de utilidade) e podemos oferecer serviços abrangentes de pré-venda e pós-venda.

Nossa garantia é de 1 ano.