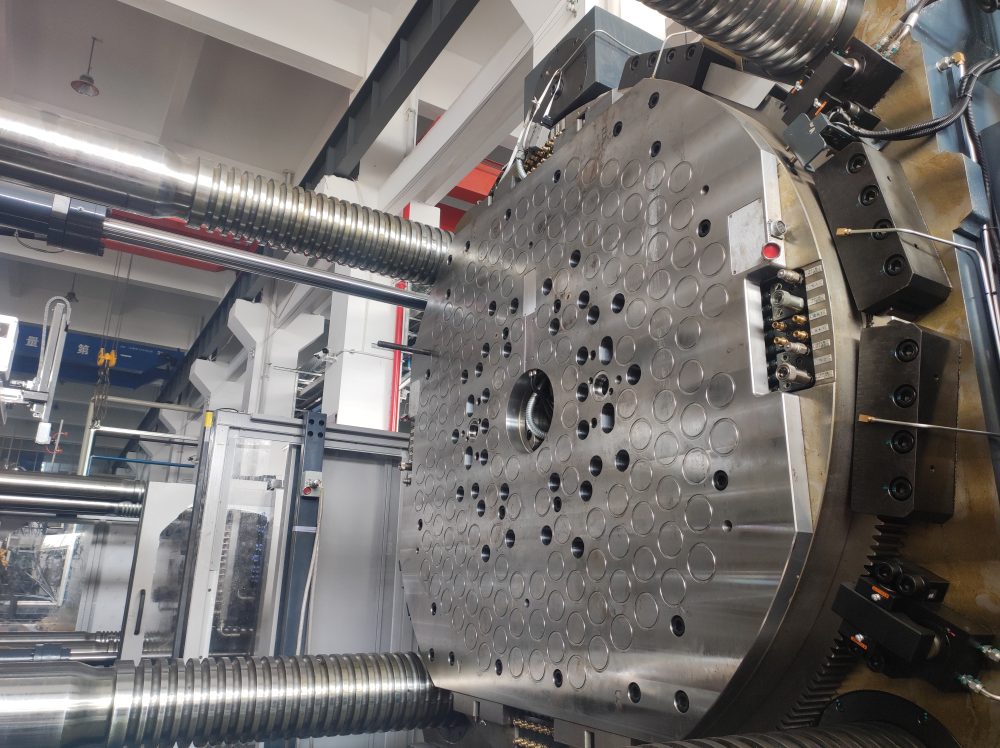

In large-scale injection molding production, efficiency and accuracy form the core competitiveness. We provided a magnetic rapid mold changing system to a Jiangsu-based company, which has successfully applied it to their 1900-ton two-color injection molding machine, achieving a breakthrough improvement in production efficiency.

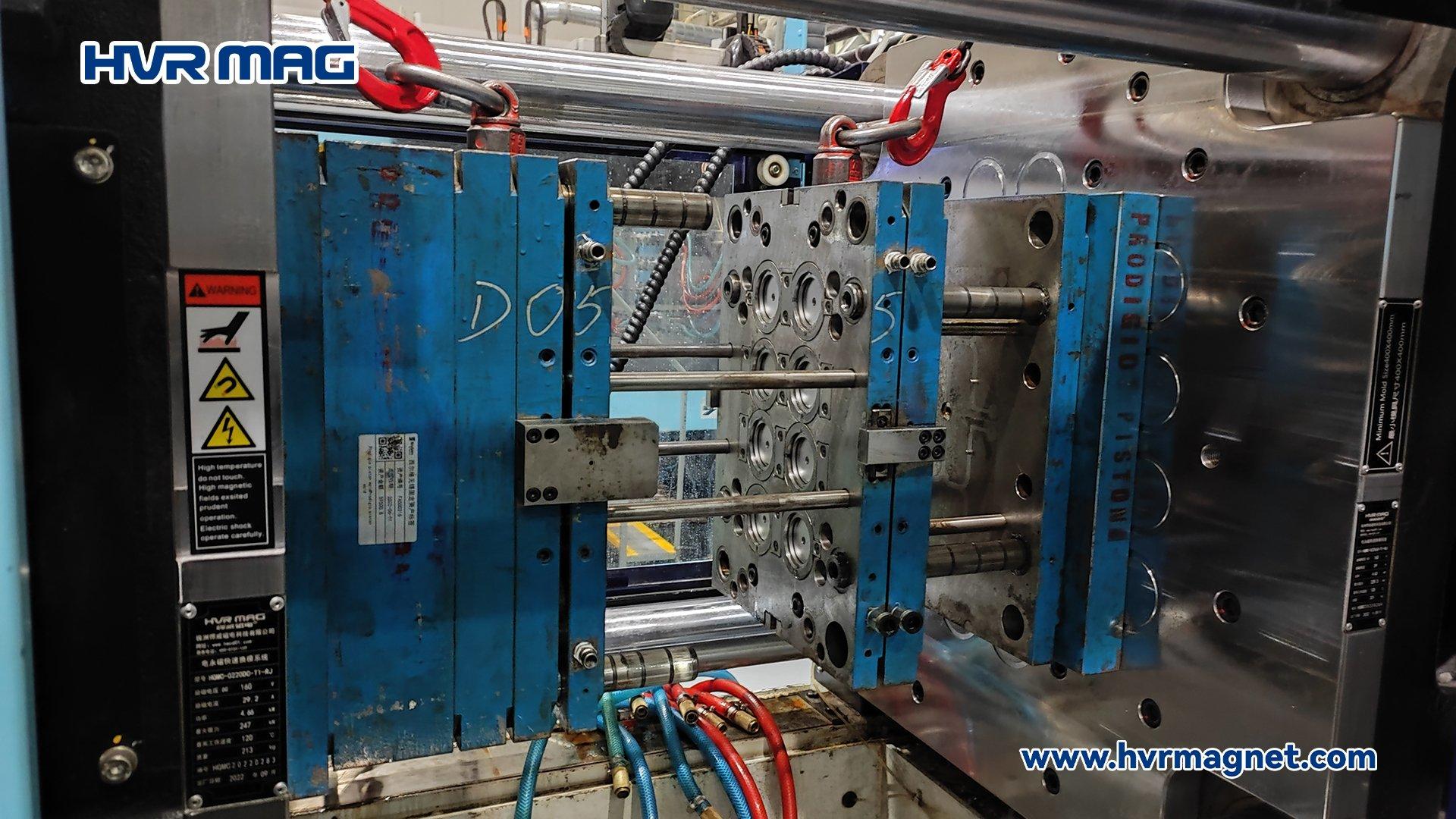

Previously, the customer’s hydraulic clamping system took up to 2.5 hours for mold replacement, and oil pressure fluctuations affected the positioning accuracy, causing the two-color injection molded products to have only an 89% yield rate. Moreover, the frequent switching of rotating pressure plates imposed higher demands on mold changing speed.

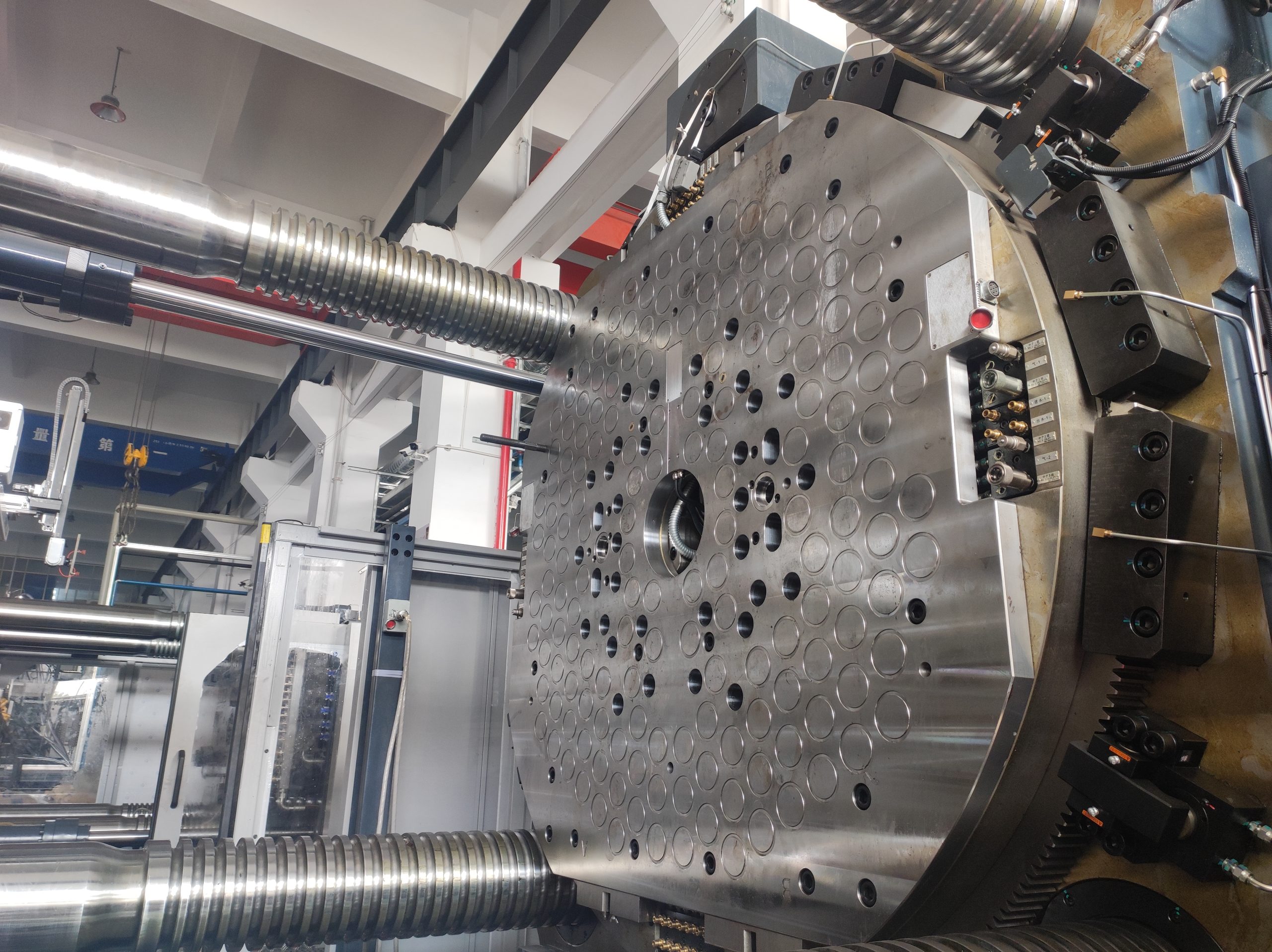

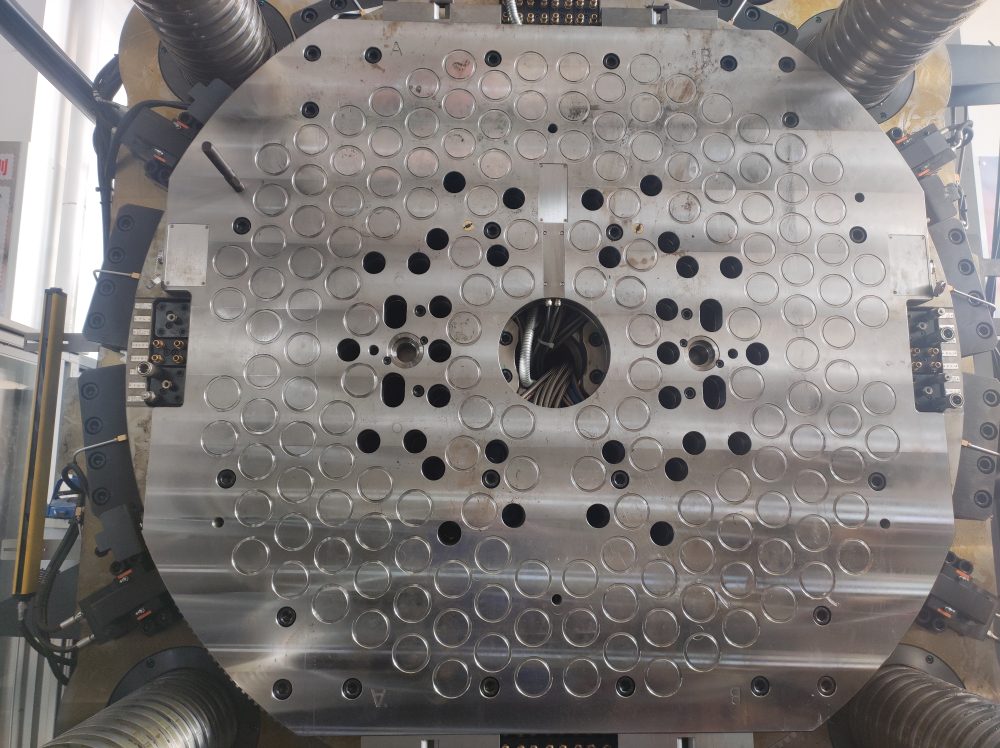

Our solution is a customized magnetic template that ensures zero displacement under a 1900-ton locking force. It comes with intelligent safety protection, integrating multiple safety measures such as pressure sensors, misalignment sensors, and distance sensors, with an error of ≤±0.05mm to eliminate the risk of mold pressing.

The original hydraulic system required 150 minutes for mold changing, had an 89% product yield, and an average daily production capacity of 22 molds. In contrast, the magnetic mold changing system reduces the mold changing time to 10 minutes, increases the product yield to 99%, and raises the daily production capacity to 38 molds. As the customer feedback stated, “The magnetic system not only solves the problem of positioning drift in two-color injection molding but also enables us to achieve flexible production of multiple varieties in a single day, reducing mold change energy consumption by 60%.”

This case confirms the application value of magnetic mold changing technology in large multi-color injection molding machines. We look forward to providing more customers with efficient, stable, and intelligent mold management solutions!

https://www.hvrmagnet.com/category/magnetic-mold-die-clamping-system-3.html