Magnetic gripper for Industrial Automation

- Magnetic gripper can handle a variety of material sizes and shapes including items with holes

- Magnets do not change their magnetic state when power failure

- Control unit could be integrated to the PLC system of robot

- Less energy comsumption

- Low-maintenance

- Compact and powerful

Product By Application

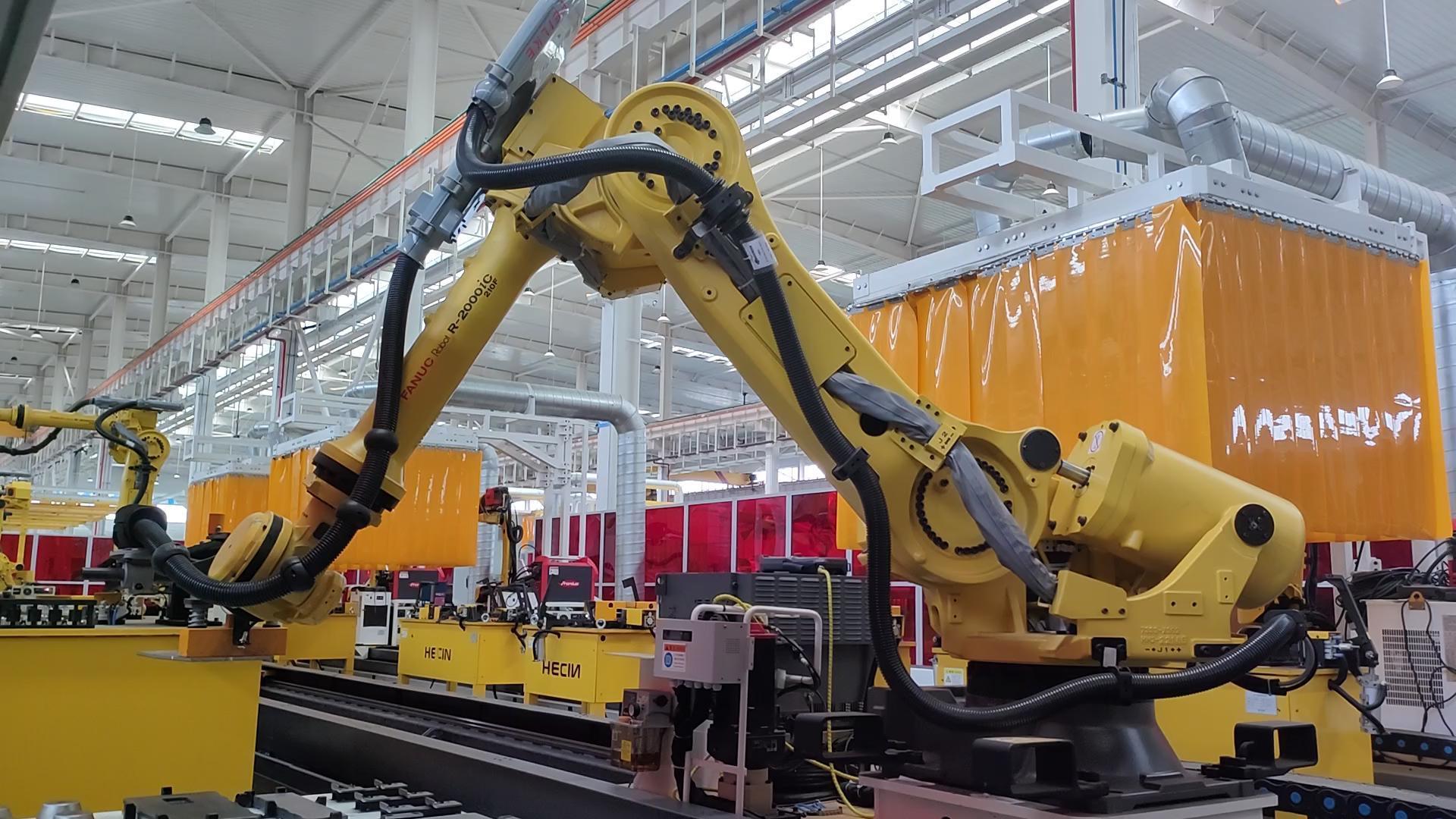

HVRMAG’s magnetic gripper can be used as magnetic grippers to pick, lift, load, place, transfer of ferrous parts for robot arm and automation line as an end-of arm-tool.

The end-of-arm tools can handle kinds of steel parts with high precision, reliability, operate stably in various automation scenarios.

Magnetic Gripper can quickly and reliably grip metal workpieces, reducing handling time and improving production efficiency.

Fixture tooling can accurately locate workpieces and ensure accurate docking of various components during welding.

Product By Function

Designed for specific needs, HVRMAG’s magnetic gripper offer a range of functionalities and different working conditions such as used for loading and unloading in cutting system, welding,bending,palletizing,etc.

In the loading process, raw materials can be quickly and accurately placed in designated locations. In the unloading process, the cut workpiece can be safely removed, ensuring the smooth progress of the entire process.

It has strong magnetic force and can firmly fix the workpiece during the welding process, ensuring the accuracy and stability of the welding. And it can adapt to workpieces of different shapes and sizes.Make sure welding quality.

Powerful magnetic force ensures the stability of the workpiece during the bending process, and it can also reduce vibration and displacement during the bending process, lower the scrap rate, and improve production efficiency.

It can quickly and accurately place workpieces on pallets, ensuring the stability and neatness of palletizing. The highly precise operation greatly improves palletizing efficiency.Reduced the burden of manual operation.

Magnetic Robot Gripper

In addition to lifting and workholding, electro permanent magnets can be used as magnetic grippers for robots to pick, lift, load, place, transfer of ferrous parts, or as magnet clamps in welding line.With the trend of “Industry 4.0”, electro-permanent magnets will be more and more widely applied to intelligent plant in automation applications in the near future.

What is HVRMAG Magnetic Gripper

Magnetic gripper is a transfer device for automation and robots, utilizing electro permanent magnetic modules and magnetic grippers for manipulation, clamping and moving of workpieces with various shapes and weight.

The technology of the double magnet uses electrical power only for few seconds in activation “MAG” and deactivation “DEMAG”cycles. The workpiece will not fall down due to the power outage.

Followed with “Industry 4.0” trend, magnetic grippers would be more and more widely applied to intelligent plant in the near future in automation applications such as:

- Transfer lines • Conveyor lines

- General engineering • Pick and place equipment

- Robotics • Packaging machinery

- Palletising/depalletising systems

Product Feature Box

Magnets for Industrial Automation, with its unique advantages, have become a key force driving the process of industrial automation.

Only uses electricity in MAG & DEMAG phase, saving energy up to 95%.

Short cycle time,magnetization/demagnetization with in 2 seconds.

Lightweight structure to maximise the end-of-arm capacity.

Magnetic force can remain even in a sudden power failure.

No moving parts inside nearly zero maintenance cost.

Customised design for perfect pick-up of any workpiece.

Resource

Click on the link to learn more.Choose the appropriate magnet based on your working conditions

Click on the link to learn more about our products. Fill in the form below to receive the brochure directly to your email.

Click on the link to learn more about our magnetic slolutions in all kinds of application.

Request A Quote

The professional magnetic gripper solution and quotation will be provided based on your applications and requirements.

You’ll receive exclusive access to new product releases, technical insights, and industry achievements. Don’t miss out on this opportunity to stay informed and ahead of the curve in the world of magnet technology.